Automatic adjusting system for indoor temperature of transformer substation

An indoor temperature and automatic adjustment technology, applied in the field of substations, can solve the problems of limited location of vents, poor ventilation and heat dissipation, and poor local ventilation and heat dissipation, so as to reduce equipment load loss, increase equipment load capacity, The effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

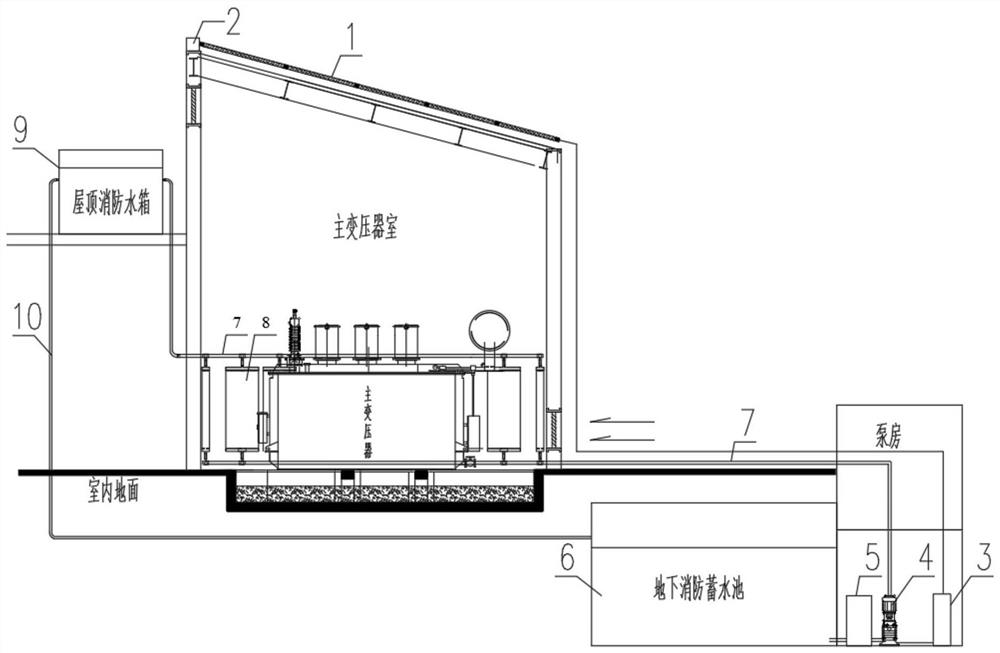

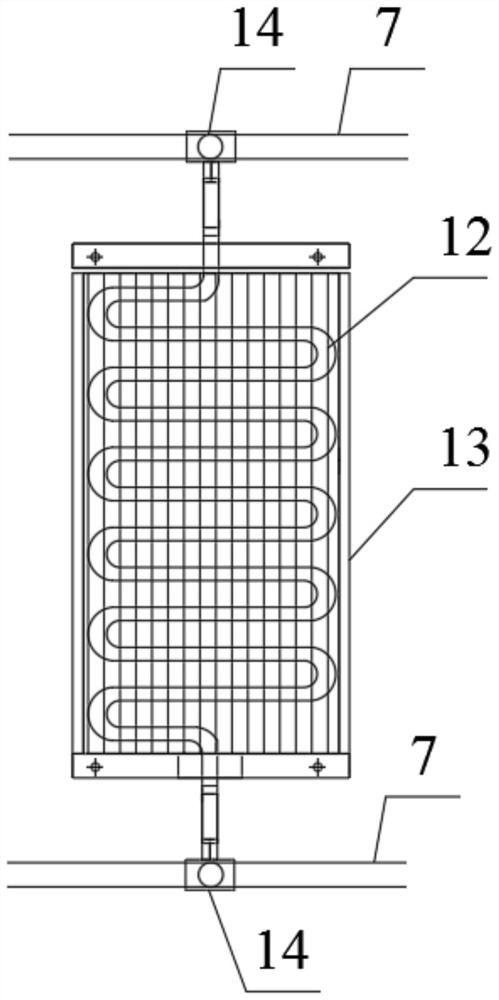

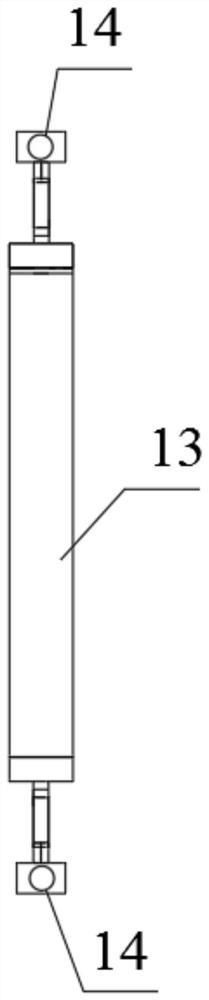

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] It should be noted that due to the fire management requirements of the substation, the substation is usually provided with an underground fire fighting reservoir 6 and a roof fire fighting water tank 9 and a pump room matched with the underground fire fighting reservoir 6, and the underground fire fighting reservoir 6 and the roof fire fighting water tank 9. There is a large amount of water stored in the substation. Through these existing equipment resources and water resources, an effective heat exchange is formed, which improves the operating environment of the indoor equipment of the substation, thereby improving the operating life of the indoor equipment in the substation, increasing the load capacity of the equipment, and reducing the load loss of the equipment. effect,

[0031] The present invention proposes a substation indoor temperature automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com