Sludge reduction and resourceful treatment system for waterworks

A waterworks and treatment system technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as high moisture content of sludge and low utilization rate of resources , to achieve the effect of high waste utilization rate, small footprint and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

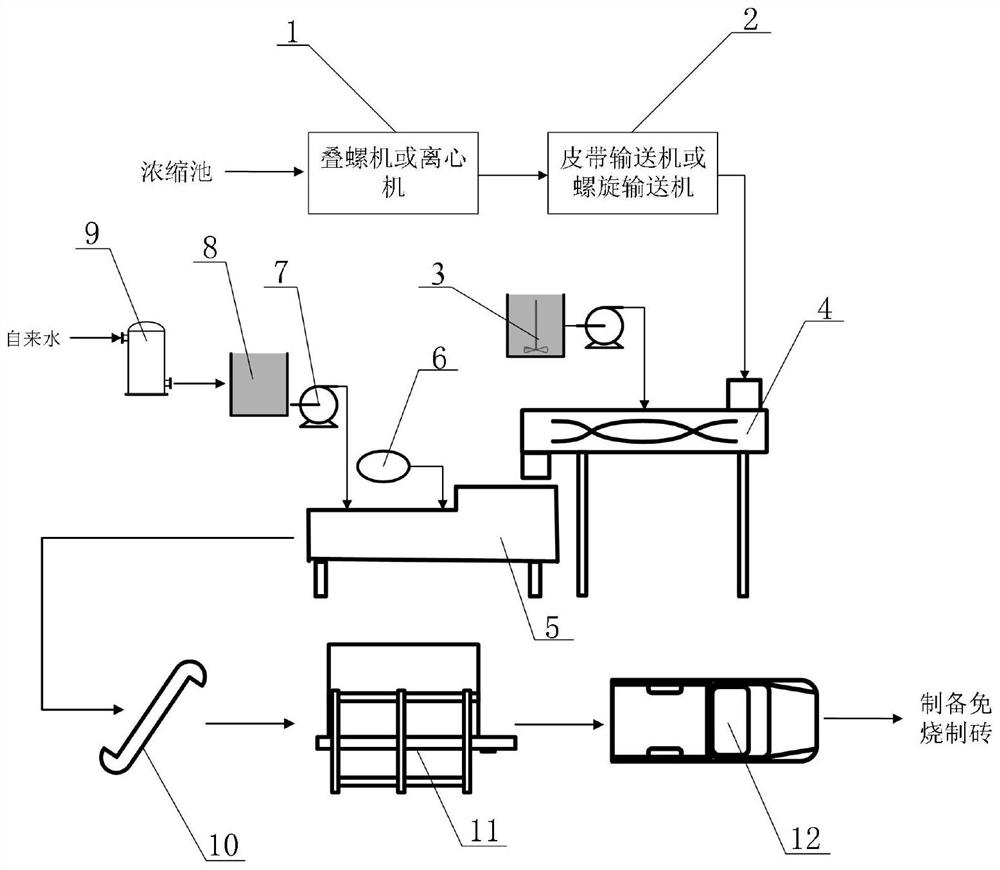

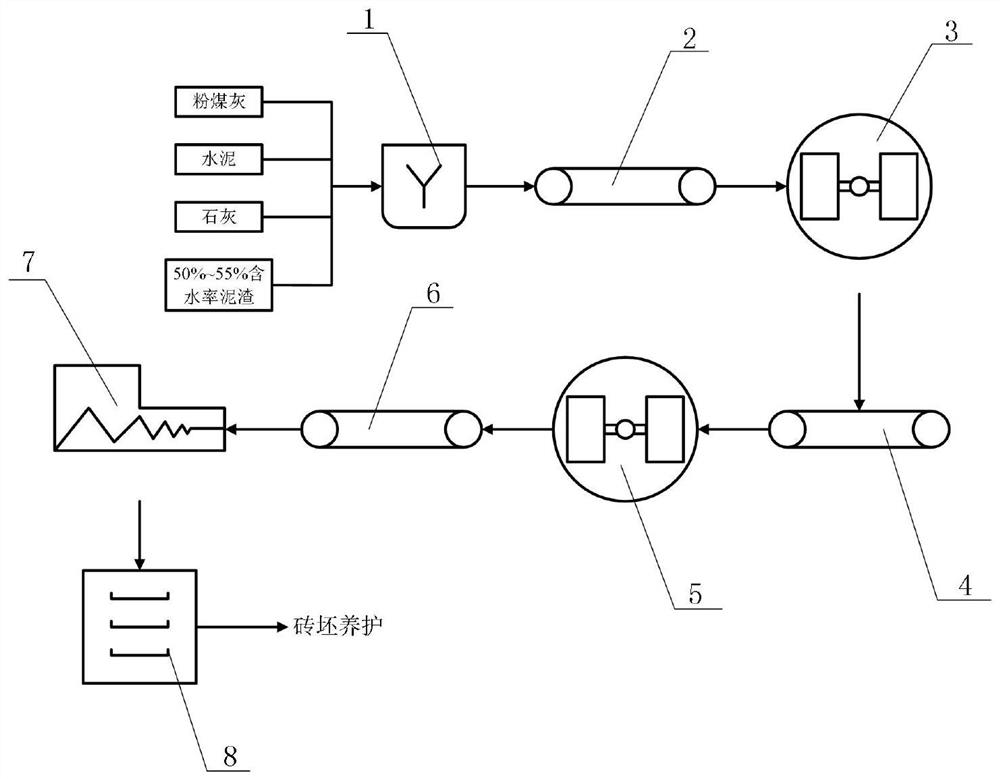

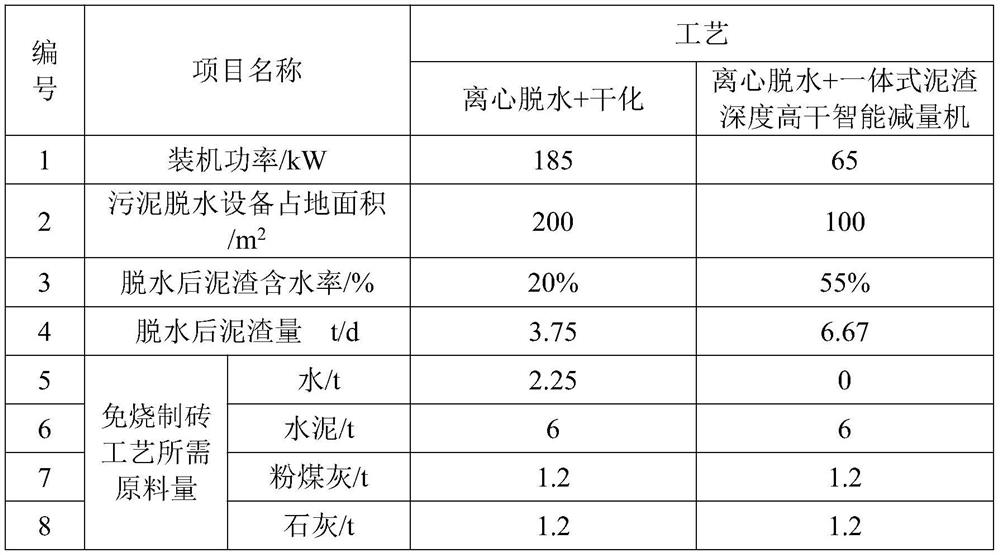

Embodiment 1

[0076] The sludge to be treated in a water plant in Shanghai is 10tDS / d. After the sludge is concentrated and precipitated in the concentration tank, the moisture content of the sludge is 98.5%. A 354 type screw stacker is used to dehydrate and reduce the sludge with high moisture content. It is connected to the sludge inlet of the screw stacker through a mud feed pump. The PAM agent concentration is prepared according to 1.5‰, and the agent is based on the absolute dry sludge quality. The final sludge moisture content is 73-75%. The sludge discharge end of the screw stacker is connected to the sludge inlet of the sludge conditioning reactor through a belt conveyor, and the conditioning agent dosing system is connected to the conditioning reactor through a pipeline. Reactor, 73-75% moisture content sludge and conditioner are conditioned and modified in the sludge conditioning reactor to improve the pressure resistance of the sludge and release the interstitial water, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com