Joint mortar for improving durability of new and old concrete joint surface

A new and old concrete, joint surface technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effect of simple production method, high ball effect, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

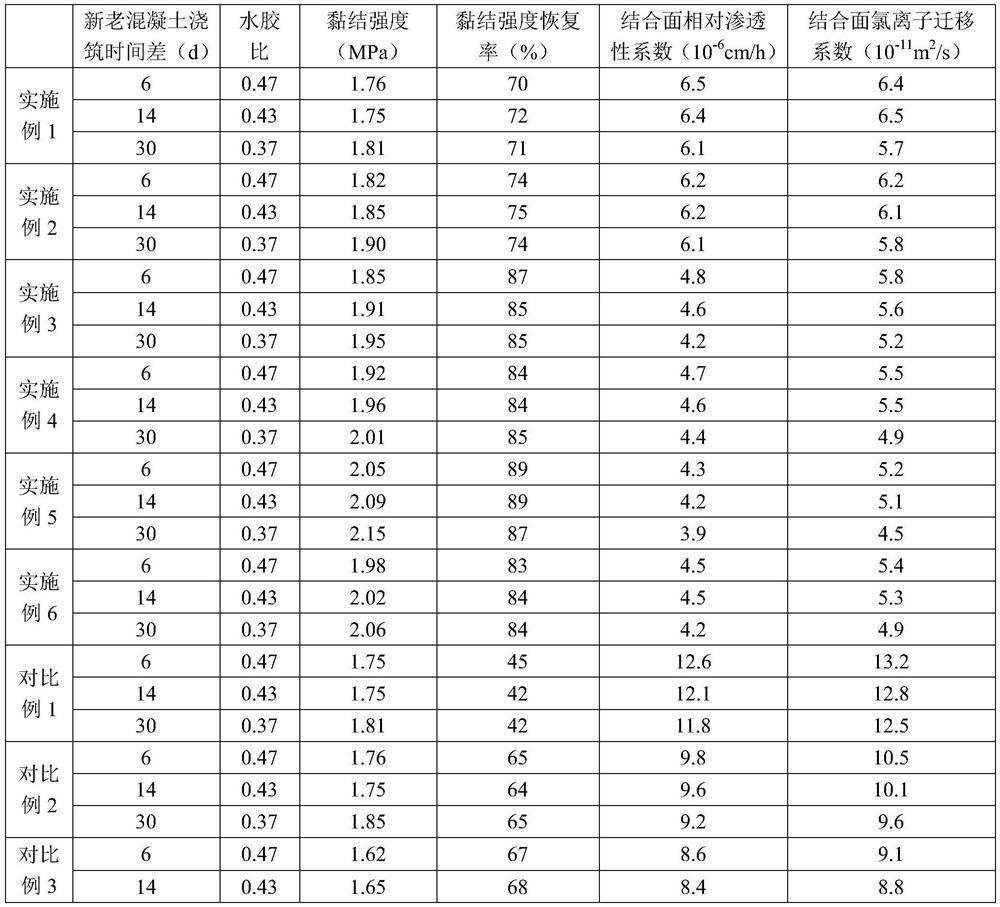

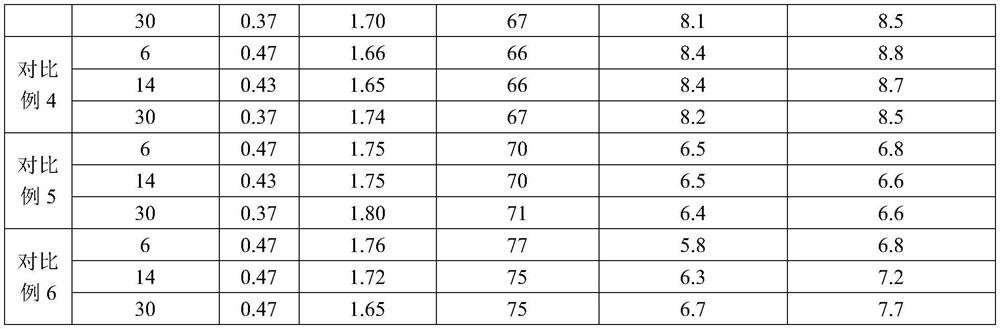

Examples

Embodiment 1

[0034] A joint mortar for improving the durability of new and old concrete joint surfaces. parts, 3 parts of modified fibers, and 5 parts of polycarboxylate powder water reducing agent. Weigh the mixing water according to the water-to-binder ratio of 0.47, 0.43 and 0.37, and mix the mortar and mixing water evenly before use.

[0035] Among them, the mineral admixture is composed of fly ash, fly ash microbeads and nano-SiO 2 According to the mass ratio of 40:40:20, the fly ash is grade I ash, the water demand ratio of fly ash microbeads is 84%, the activity index is 88%, and the nano-SiO 2 Specific surface area 200m 2 / g.

[0036]The self-healing microcapsules are prepared according to the following method: (1) Preparation of capsule core: put 100 parts of repairing agent into the disc granulator, set the rotation speed of the drum to 35 rpm, and simultaneously add 20 parts of water by spraying, Make the repairing agent powder agglomerate into a spherical shape as the core ...

Embodiment 2

[0039] A joint mortar for improving the durability of new and old concrete joint surfaces. parts, 3 parts of modified fibers, and 5 parts of polycarboxylate powder water reducing agent. Weigh the mixing water according to the water-to-binder ratio of 0.47, 0.43 and 0.37, and mix the mortar and mixing water evenly before use.

[0040] Among them, the mineral admixture is composed of fly ash, fly ash microbeads and nano-SiO 2 According to the mass ratio of 35:45:20, the fly ash is grade I ash, the water demand ratio of fly ash microbeads is 84%, the activity index is 88%, and the nano-SiO 2 Specific surface area 200m 2 / g.

[0041] The self-healing microcapsules are prepared according to the following method: (1) Preparation of capsule core: put 100 parts of repairing agent into the disc granulator, set the rotation speed of the drum to 65 rpm, and simultaneously add 30 parts of water by spraying, Make the repair agent powder agglomerate into a spherical shape as the core of...

Embodiment 3

[0044] A joint mortar for improving the durability of new and old concrete joint surfaces. parts, 3 parts of modified fibers, and 5 parts of polycarboxylate powder water reducing agent. Weigh the mixing water according to the water-to-binder ratio of 0.47, 0.43 and 0.37, and mix the mortar and mixing water evenly before use.

[0045] Among them, the mineral admixture is composed of fly ash, fly ash microbeads and nano-SiO 2 According to the mass ratio of 45:35:20, the fly ash is grade I ash, the water demand ratio of fly ash microbeads is 84%, the activity index is 88%, and the nano-SiO 2 Specific surface area 200m 2 / g.

[0046] The self-healing microcapsules are prepared according to the following method: (1) Preparation of capsule core: put 100 parts of repairing agent into the disc granulator, set the rotation speed of the drum to 65 rpm, and simultaneously add 30 parts of water by spraying, Make the repair agent powder agglomerate into a spherical shape as the core of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com