Press-fitting insensitive high polymer bonded explosive and preparation method thereof

A high polymer and bonding technology, which is applied in the field of press-packed insensitive high polymer bonded explosives and its preparation, can solve the problems of low coating degree, wide particle size distribution, poor adhesion between binder and explosive particles, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of press-packed insensitive high polymer bonded explosive, comprising the following steps: mixing 1,1-diamino-2,2-dinitroethylene and an anti-solvent to obtain an anti-solvent suspension;

[0024] Dissolving the binder into the anti-solvent suspension to obtain a blended suspension;

[0025] Ultrasonic dispersion and mechanical stirring are carried out simultaneously for the blended suspension to obtain a stable suspension;

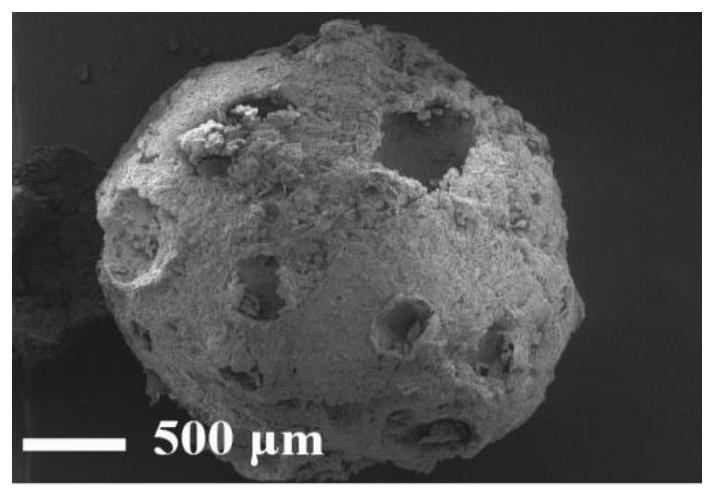

[0026] The stable suspension is spray-dried to obtain a press-packed insensitive high polymer bonded explosive.

[0027] In the present invention, without special instructions, the raw materials used are all commercially available commodities well known in the art.

[0028] In the present invention, 1,1-diamino-2,2-dinitroethylene is mixed with an anti-solvent to obtain an anti-solvent suspension.

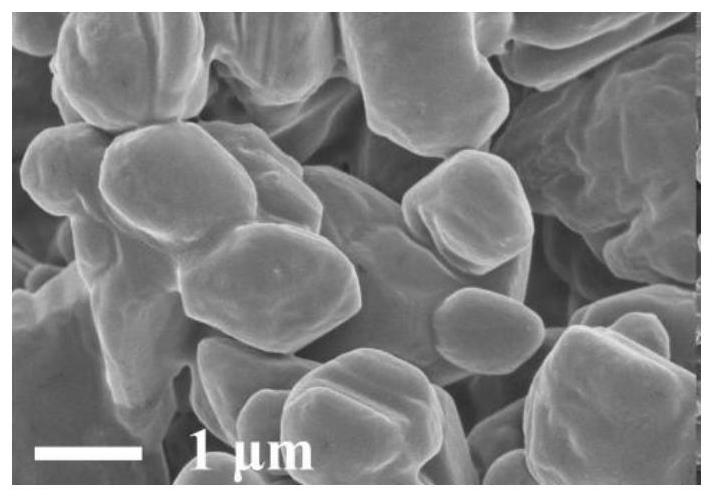

[0029] In the present invention, the median particle size D of the 1,1-diamino-2,2-dinitroethylene 50 Pr...

Embodiment 1

[0046] The composition and preparation process parameters of the pressure-packed polymer bonded explosive (calculated by mass percentage) of the present embodiment are as follows:

[0047] Main explosive: FOX-7, 95%; binder system: ethylene-vinyl acetate copolymer, 1%; vinylidene fluoride and hexafluoropropylene copolymer, 4%.

[0048] The concrete steps of this embodiment are:

[0049] (1) take by weighing FOX-7 and add in ethyl acetate, wherein the mass ratio of FOX-7 and ethyl acetate is 2:98, obtain anti-solvent suspension; Take by weighing ethylene-vinyl acetate copolymer and vinylidene fluoride and The hexafluoropropylene copolymer is dissolved in the anti-solvent suspension to form a mixed suspension;

[0050] (2) under the temperature condition of 25 ℃, the container where the blended suspension prepared in step (1) is placed is placed in an ultrasonic disperser, the ultrasonic power is 270W, and a mechanical stirrer is used to stir at the same time, and the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com