Coaxial cable manufacturing process and equipment

A technology for manufacturing equipment and coaxial cables, applied in the field of coaxial cable manufacturing process and equipment, can solve the problems of the outer sheath of the cable being easily damaged and broken, affecting the processing quality of the cable, etc., to achieve the effect of energy saving and improving the cleanliness of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

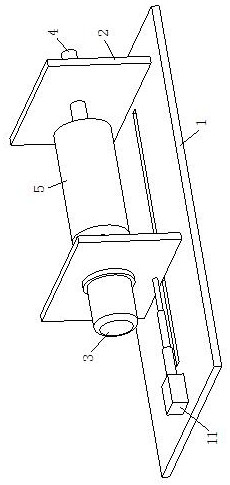

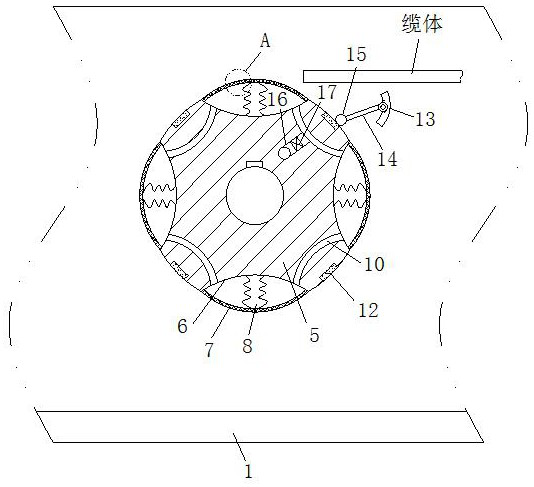

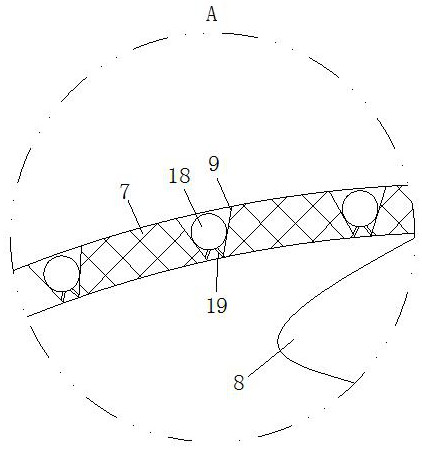

[0033] see Figure 1-Figure 2 As shown, a coaxial cable manufacturing equipment according to an embodiment of the present invention includes a bottom plate 1; a pair of support plates 2 are connected on the top surface of the bottom plate 1, and a motor 3 is installed on the plate surface of one support plate 2 , the output end of the motor 3 is connected with a rotating rod 4, and the other end of the rotating rod 4 extends to another support plate 2 and is connected with it in rotation. The rotating rod 4 is provided with a reel 5, so Several groups of grooves 6 are opened on the outer ring side wall of the take-up drum 5, and the outer end of the side wall of the groove 6 is connected with a bulging elastic film 7, and the elastic film 7 and the inner end of the groove 6 are connected. An elastic member 8 is connected between, and the surface of the elastic film 7 is provided with a number of air outlet holes 9; after the preparation of the coaxial cable in the prior art, t...

Embodiment 2

[0041] like Figure 4 As shown, Comparative Example 1, in which another embodiment of the present invention is: the side wall of the take-up drum 5 is provided with a slot 20, and the outer end of the side wall of the slot 20 is symmetrically provided with a chute , a slide plate 21 that is slidably connected to the side wall of the chute, a spring is connected between the slide plate 21 and the inner end of the chute, and the inner end of the chute is installed with a sliding plate 21 capable of attracting The electromagnet 22, an elastic tympanic membrane 23 is connected to the side wall of the inner end of the tympanic membrane 23, and the side wall of the tying slot 20 inside the tympanic membrane 23 is provided with a conducting groove 24 that communicates with the inner end of the chute; During the initial winding, the two electromagnets 22 can attract the slide plate 21 to make the card slot 20 open, and then the end of the cable body is placed inside the card slot 20. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com