Process for preparing 5-methyl pyrazine-2-carboxylic acid

A technology of methylpyrazine and methylbenzopyrazine, which is applied in the field of preparation of pharmaceutical intermediates, can solve problems such as difficult production, high product impurities, and unacceptable production costs, and achieves improved purity, abundant sources, and preparation The effect of the method is easy to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

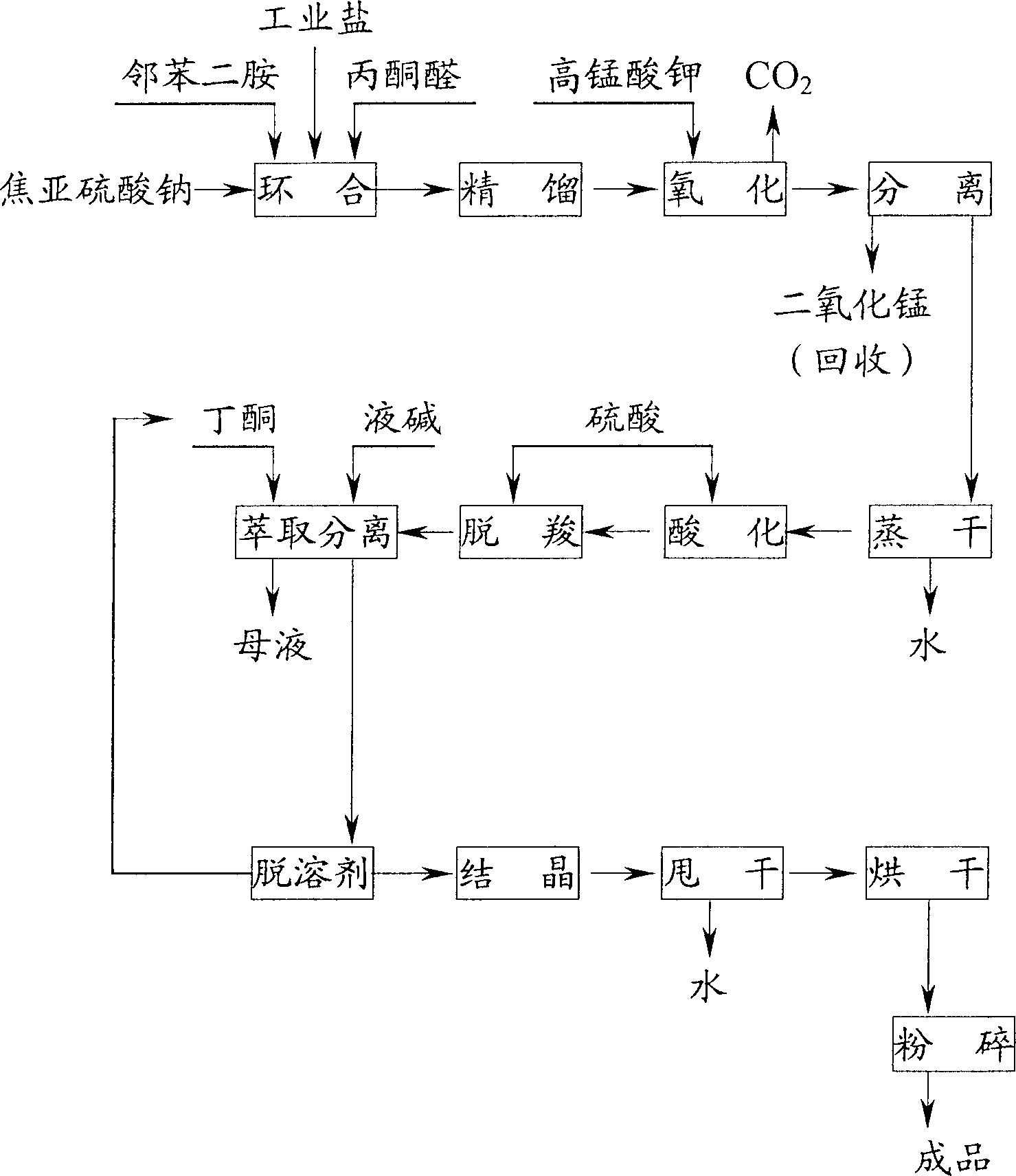

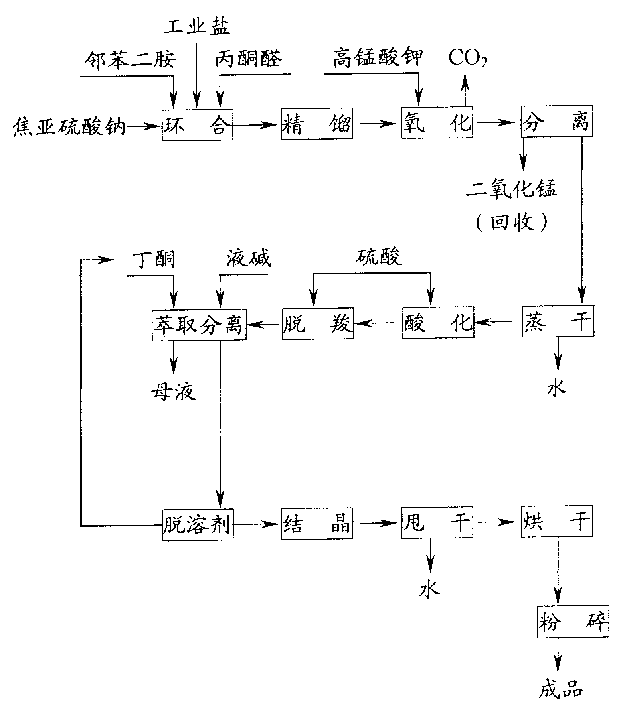

Method used

Image

Examples

Embodiment

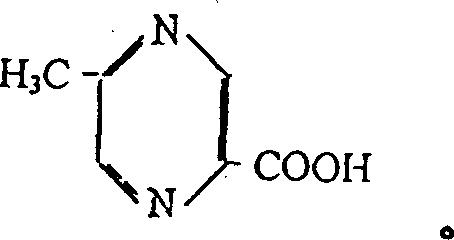

[0018] (1) The main chemical reactions involved in the preparation method

[0019] ① ring closure:

[0020]

[0021] ② Oxidation:

[0022]

[0023] ③ Acidification:

[0024]

[0025] Decarboxylation:

[0026]

[0027] raw material name

Specification

Dosage(kg / kg)

Methylglyoxal CH 3 COCHO

o-Phenylenediamine C 6 h 4 (NH 2 ) 2

Sodium metabisulfite Na 2 S 2 o 5

Potassium permanganate KMnO 4

Industrial salt NaCl

Sulfuric acid H 2 SO 4

Liquid caustic soda NaOH

Butanone CH 3 COCH 2 CH 3

Industrial products (according to 100%)

Industrial products, 98%

Industrial products, 98%

Industrial products, 98%

Industrial products, 98%

Industrial products, 98%

Industrial products, 40%

Industrial products

7.00

8.50

6.75

38.00

35.00

31.00

Appropriate amount

100

[0028] (3) Preparation steps

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com