Electronic component

A technology of electronic components and circuits, applied in the directions of printed circuit components, electrical components, circuits, etc., can solve problems such as difficulty in designing electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described below with reference to the accompanying drawings.

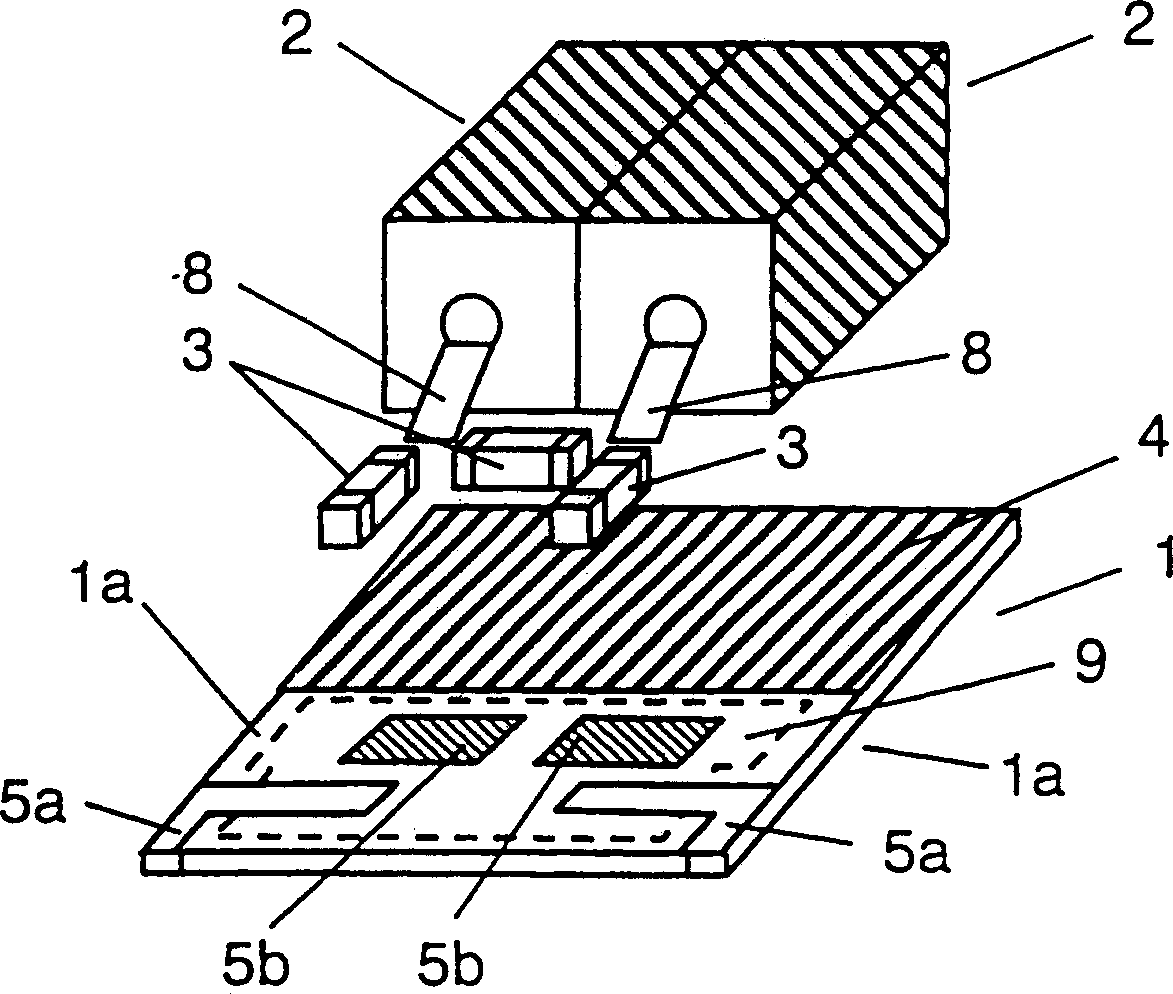

[0013] figure 1 is a partially exploded perspective view of a dielectric filter. The dielectric filter includes circuit elements such as dielectric resonators 2, chip capacitors 3 and others mounted on a substrate 1 by reflection flow soldering.

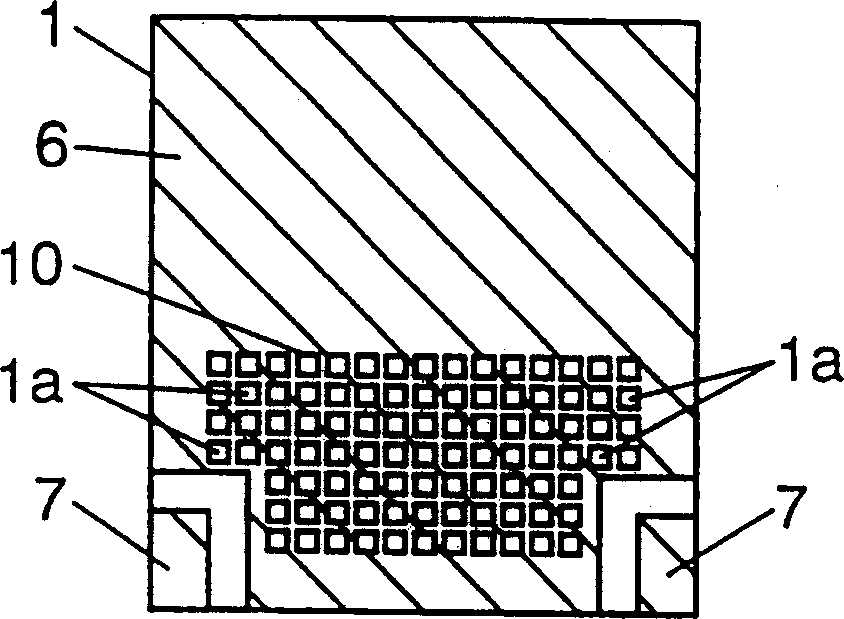

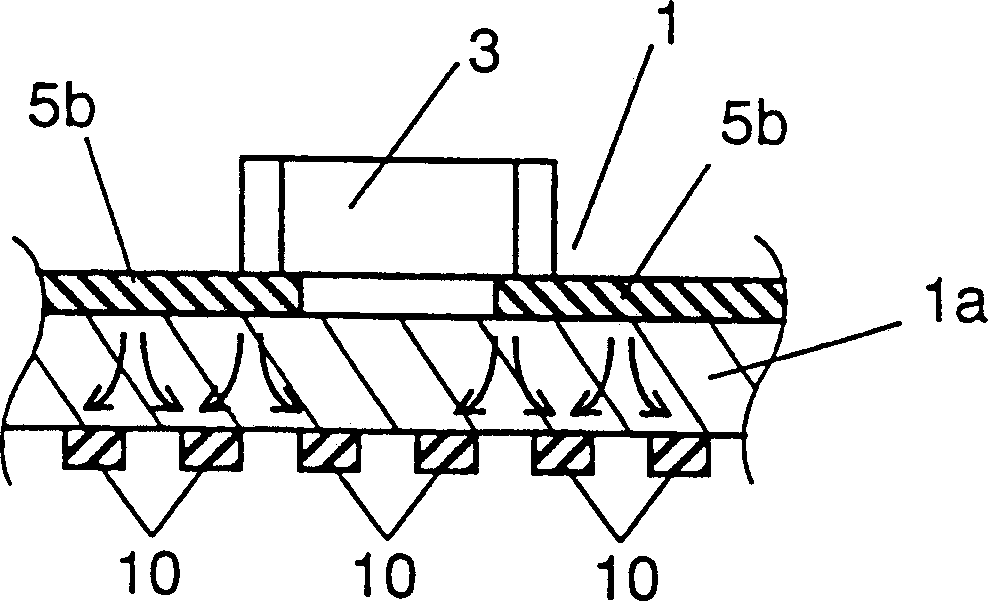

[0014] The substrate 1 comprises a rectangular bare substrate 1a made of glass epoxy resin. On the upper surface of the substrate 1, the following parts are provided: a) a ground electrode 4 for mounting the dielectric resonator 2, b) partially formed circuit electrodes 5a and 5b for mounting and connecting the chip capacitor 3 and others element. On the lower surface, a ground electrode 6 is provided to cover substantially the entire surface, as figure 2 As shown in , and the input / output electrodes 7 are provided at both ends of one side. Circuit electrodes 5a on the upper surface are coupled to input / output electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com