Treating method of metacresol production effluent

A treatment method, m-cresol technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of increasing acid consumption and treatment costs, large hydrogen peroxide The addition amount, the inability to meet the emission requirements and other problems, to achieve the effect of stable and reliable treatment effect, low treatment cost and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

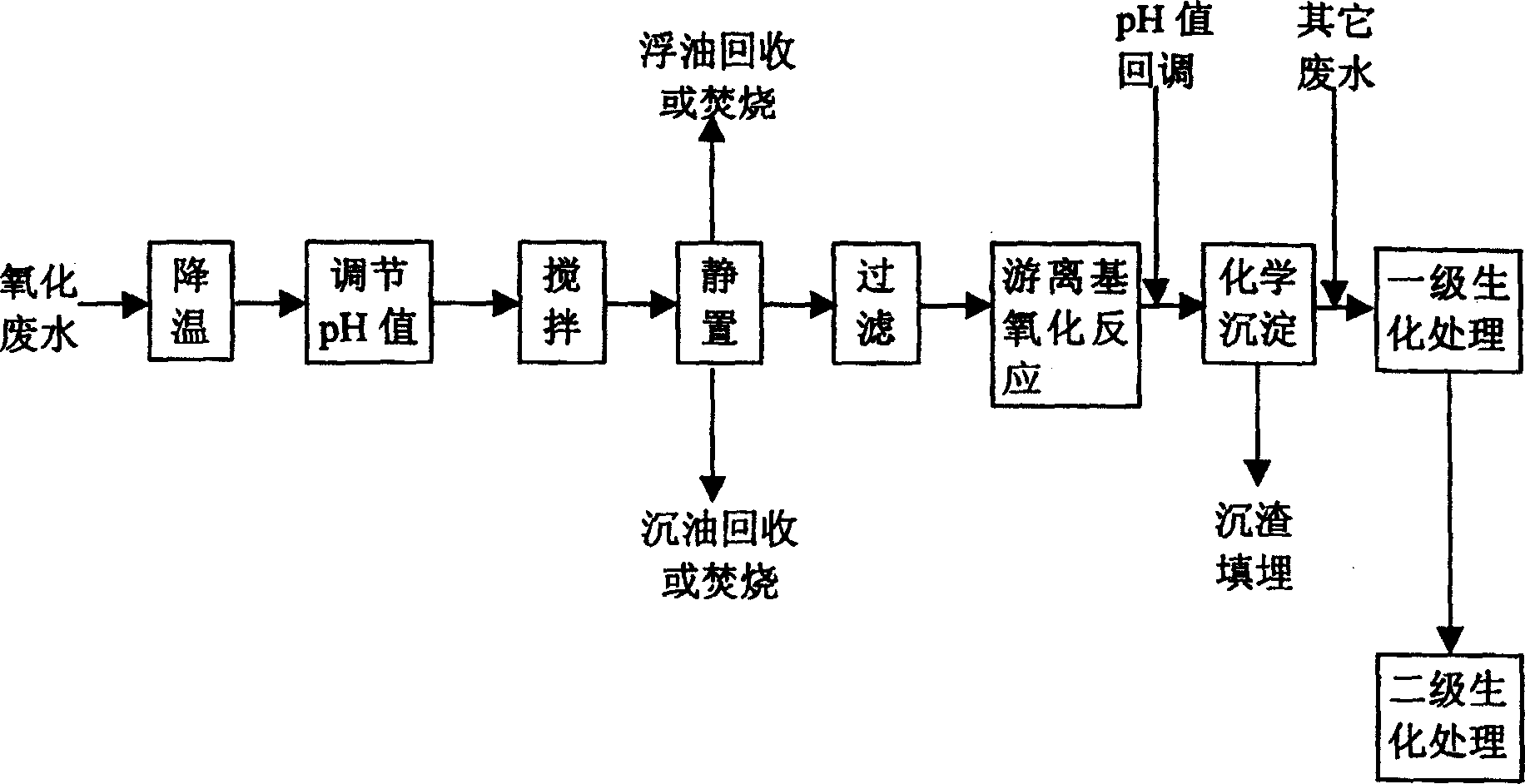

Image

Examples

Embodiment 1

[0026] Get m-cresol production oxidation wastewater 100ml (its COD Cr 78,000mg / L), after cooling down to 25°C, concentrated sulfuric acid with a concentration of 98% was added to adjust the pH of the wastewater to 4.0. Afterwards, stir rapidly at a speed of 600 rpm for 15 minutes, and stand still for 15 minutes. After removing the sunken oil and floating oil in the oxidized wastewater and filtering, according to the H 2 o 2 / COD Cr = 0.3 (w / w, pure substance weight ratio) Add hydrogen peroxide to waste water, according to Fe 2+ / H 2 o 2 = 0.25 (w / w, pure substance weight ratio) Add FeSO to wastewater 4 ·7H 2 O, the free radical reaction time is taken as 30 minutes. After the free radical reaction, a solution with a concentration of 20% NaOH was added to the oxidation wastewater to adjust the pH to 10.0. The waste water is then filtered to remove the sediment. Then the pretreated oxidized wastewater is mixed with the other two streams of wastewater for contact oxidati...

Embodiment 2

[0029] In addition to the amount of hydrogen peroxide added according to H 2 o 2 / COD Cr Except =0.4 (w / w, pure substance weight ratio), all the other conditions are with embodiment 1.

[0030] COD of wastewater after adjusting pH=4.0, rapid stirring, standing still, separation and filtration Cr 61,223mg / L, COD Cr The removal rate is 21.5%; after free radical reaction and pH adjustment = 10.0, the COD of wastewater after filtration Cr 21,185mg / L, total COD Cr The removal rate was 72.8%, the effluent CODcr was 572mg / L after contact oxidation treatment, and the biochemical reaction was running well.

Embodiment 3

[0032] In the acidification pretreatment step of the oxidized wastewater, the pH of the oxidized wastewater was adjusted to 3.0, and the rest of the conditions were the same as in Example 1.

[0033] COD of wastewater after adjusting pH=3.0, rapid stirring, standing still, separation and filtration Cr 52,880mg / L, COD Cr The removal rate is 32.2%; after free radical reaction and pH adjustment = 10.0, the COD of wastewater after filtration Cr 20,370mg / L, total COD Cr The removal rate was 73.9%. After contact oxidation treatment, the CODcr of the effluent was 524mg / L, and the biochemical reaction was running well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com