Nano multicrystal biofilm photoelectric cell and its manufacturing method

A biofilm and production method technology, applied in the fields of nanostructure manufacturing, nanotechnology, photovoltaic power generation, etc., can solve the problems of high production and application costs, and the inability to popularize and apply in large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

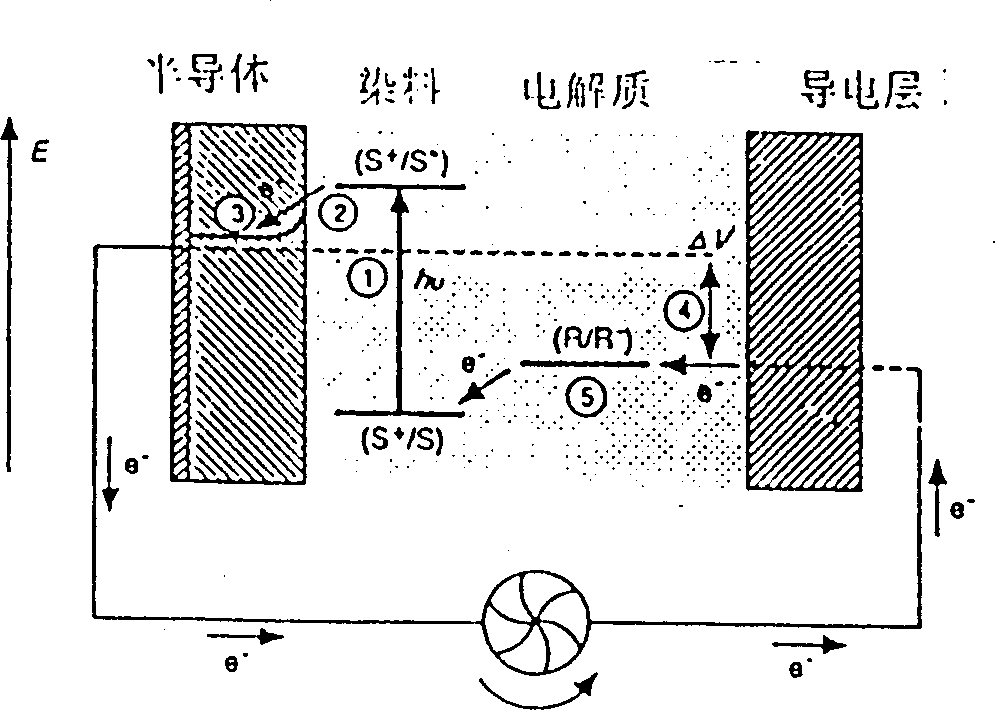

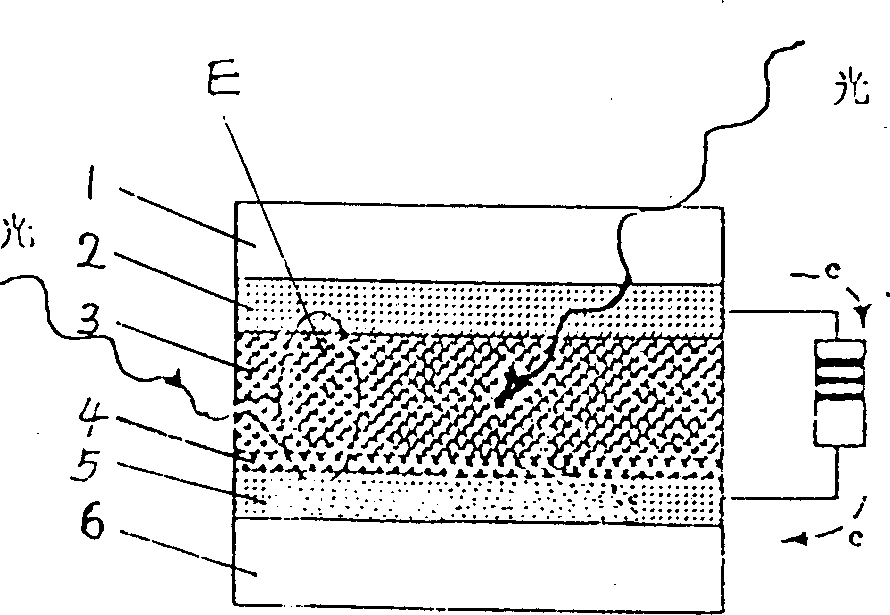

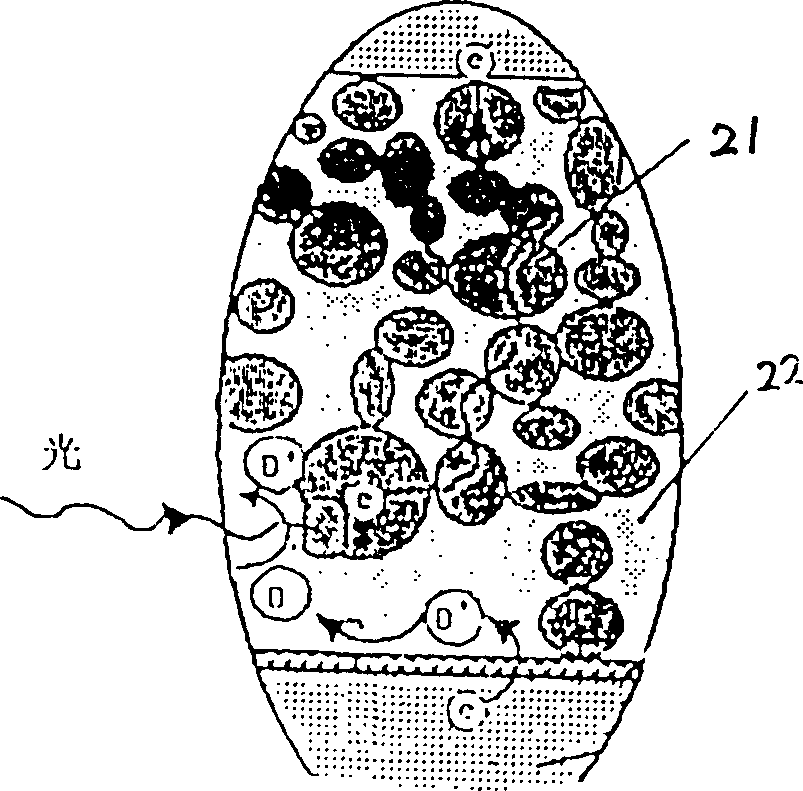

[0030] Such as figure 2 , image 3 The structure of the nano-polycrystalline biological thin film photovoltaic cell shown is as follows: it consists of a layered structure, and the structure from top to bottom is:

[0031] 1. Light-transmitting plastic film cover layer, its light transmittance is greater than 85%, and it can withstand high temperature of 200°C;

[0032] 2. SnO made by magnetron sputtering 2 Conductive film layer, film thickness 20μm, resistance less than 10Ω;

[0033] 3. Pd, Rh, Ru and other organic or inorganic dyes, ZnO, ZnS, Nb 2 o 2 or TiO 2 A semiconductor film with holes self-assembled from a semiconductor film and a latex-like redox agent, with a film thickness of 10-20 μm;

[0034] 4. The conductive film made of Ag, Au or Pt, etc., has excellent electron transfer performance, and the film thickness is 10 μm;

[0035] 5. SnO made by magnetron sputtering 2 Conductive film layer, film thickness 20μm, resistance less than 10Ω;

[0036] 6. Rollabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com