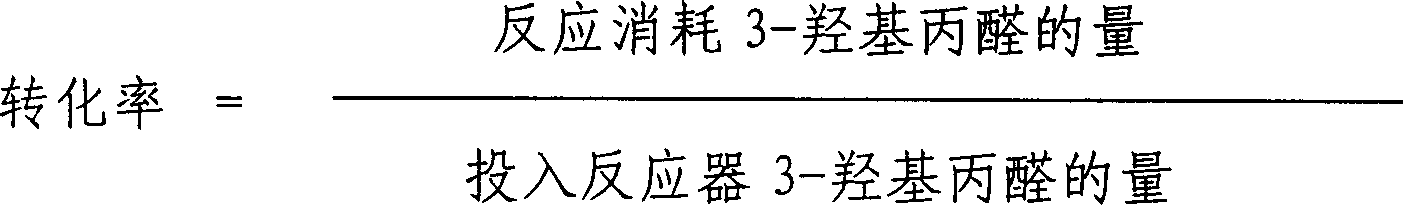

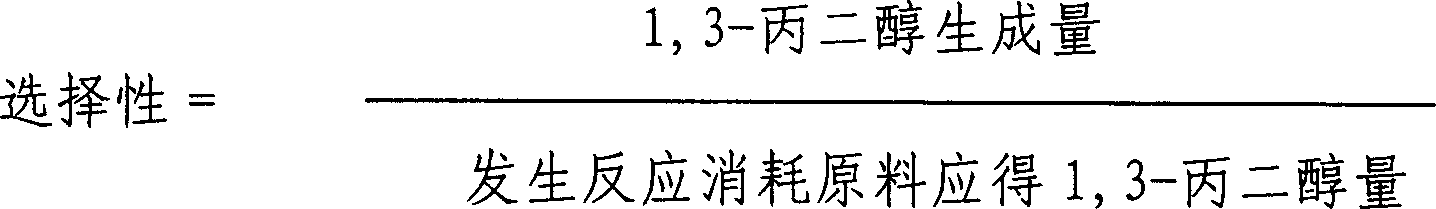

Method for preparing 1,3-propylene glycol by 3-hydroxypropionaldehyde hydrogenation

A technology of hydroxypropionaldehyde and propylene glycol, which is applied to the hydrogenation of 3-hydroxypropionaldehyde to produce 1, can solve the problems of increased production cost, easy platinum poisoning, and decreased selectivity, and achieves reduced hydrogenation production costs, mild hydrogenation conditions, The effect of activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0019] Preparation of catalyst:

[0020] Nickel nitrate and a water-soluble compound containing the promoter component A are prepared into an aqueous solution according to a certain proportion, and then the catalyst carrier is added according to the proportion, and stirred evenly. When it reaches a certain viscosity, it is extruded into strips and dried in the shade. In order to improve the strength of the catalyst and decompose the metal compounds into oxides, calcinations were carried out at 80°C, 300°C and 700°C for 3 hours, 4 hours and 5 hours, respectively. After the calcination is completed, it is naturally lowered to room temperature and loaded into the reduction reactor. When the hydrogen pressure is 0.2 MPa, the temperature is raised at 470 ° C and reduced for about 4 hours. The degree of reduction can be judged from the amount of water generated. After the reduction, it was lowered to room temperature in a nitrogen atmosphere and stored in water for later use.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com