Compsite wire with noble metal cladding

A technology of composite metal and packaging components, which is applied in the field of composite metal wire and composite metal wire manufacturing, can solve the problem of not satisfying, not giving metal wire, and not being able to connect the metal wire with 4N gold alloy and wrap it in the core of copper metal wire, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

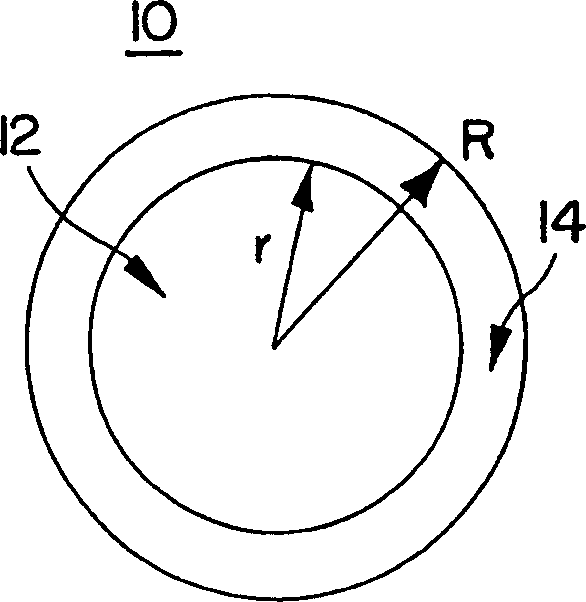

[0024] figure 1 A composite metal wire of an embodiment of the invention is shown wherein a core 12 comprising a non-noble metal is joined to an annular portion 14 of a noble metal. (Noble metals are defined as metals that are heated in air without being oxidized and include platinum, palladium, silver, or similar metals in addition to gold.) R represents the radius of the wire 10 consisting of the core 12 and the annular portion 14, And r denotes the radius of the core 12 . The amount of core material 12 relative to annular portion 14 and wire 10 is expressed as a "section ratio" measured by cross-sectional area, which is a function of the ratio of r to R (r / R).

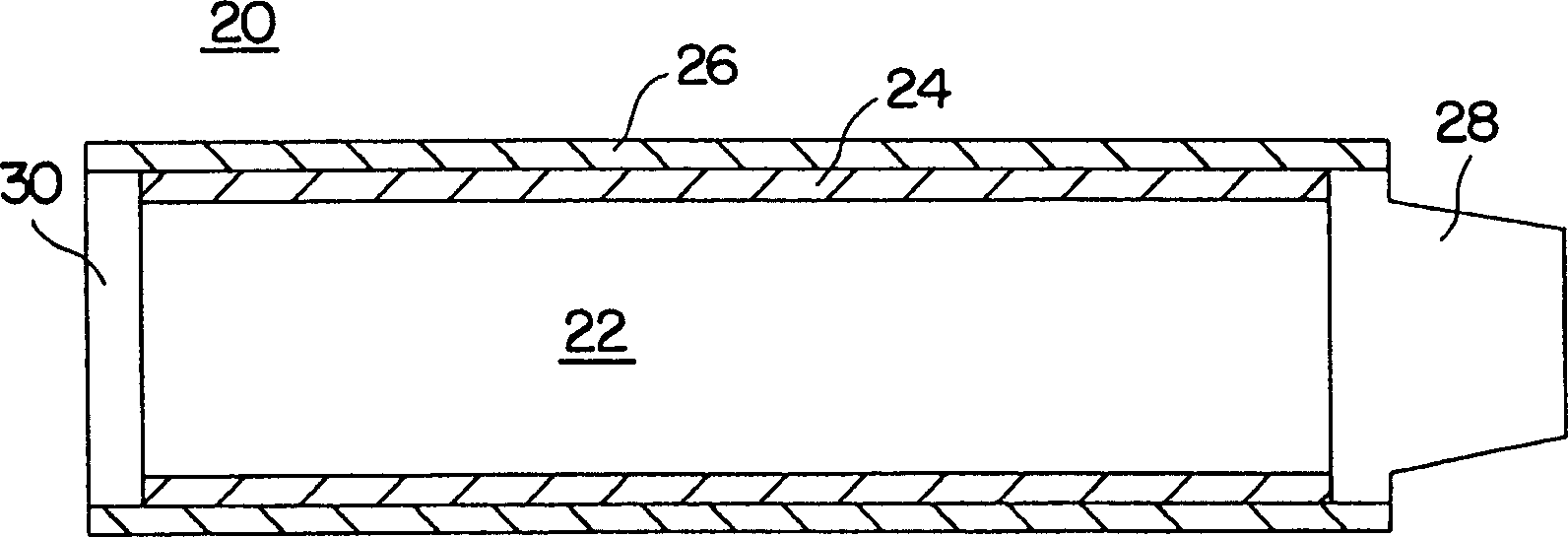

[0025] The connection is made by applying heat and pressure. The amount of heat and pressure applied will depend on the non-precious metal or metal alloy core material and the noble metal or metal alloy annular portion material used and can be readily determined by one of ordinary skill in the metallurgical arts w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com