Pipe fitting forming system based on coreless extrusion principle

A pipe fitting and principle technology, applied in the field of non-cutting forming system, can solve the problems of complicated lead melting and cleaning work, surrounding environmental pollution, low work efficiency, etc., and achieve the effects of saving investment in pollution prevention, simplifying the process, and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

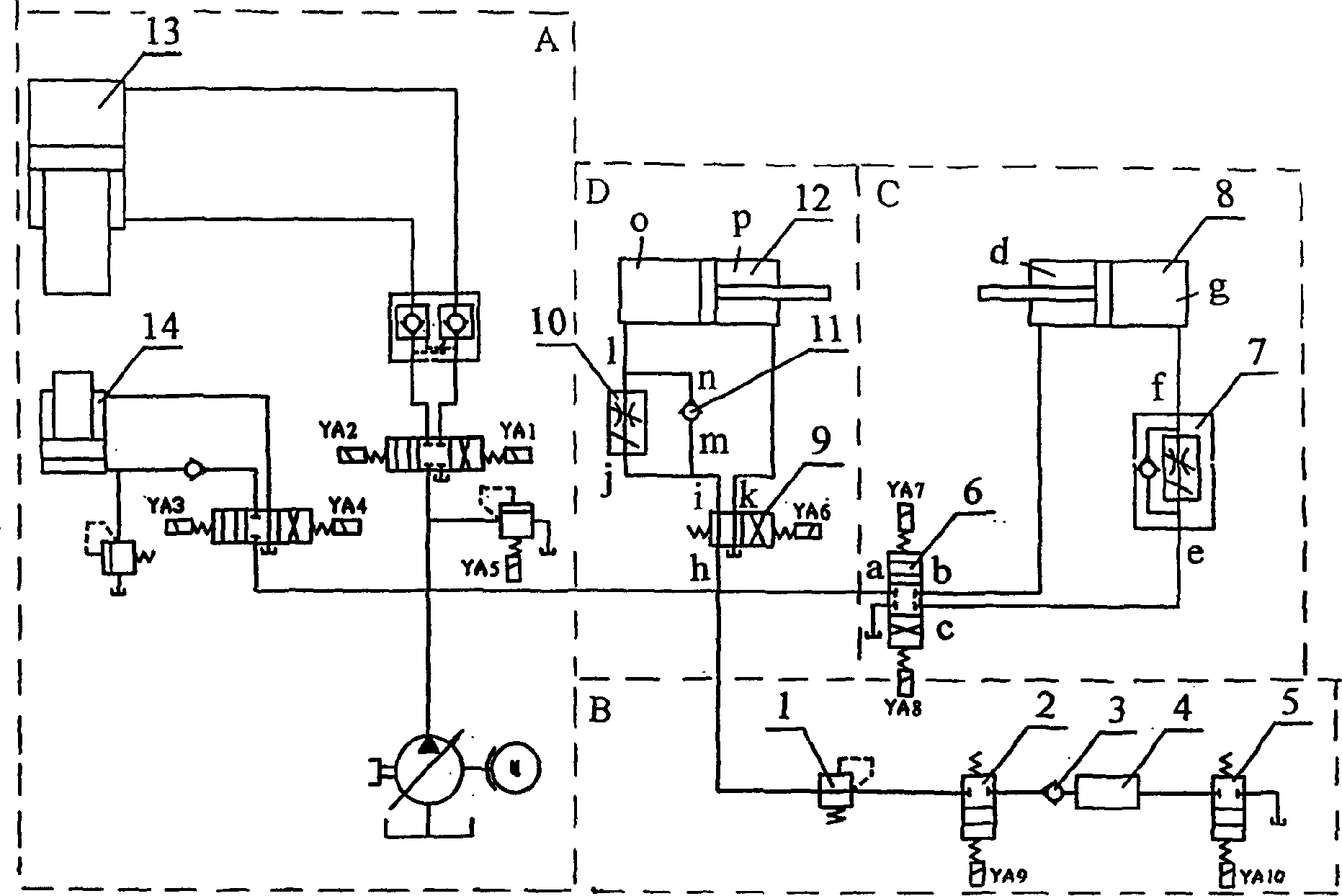

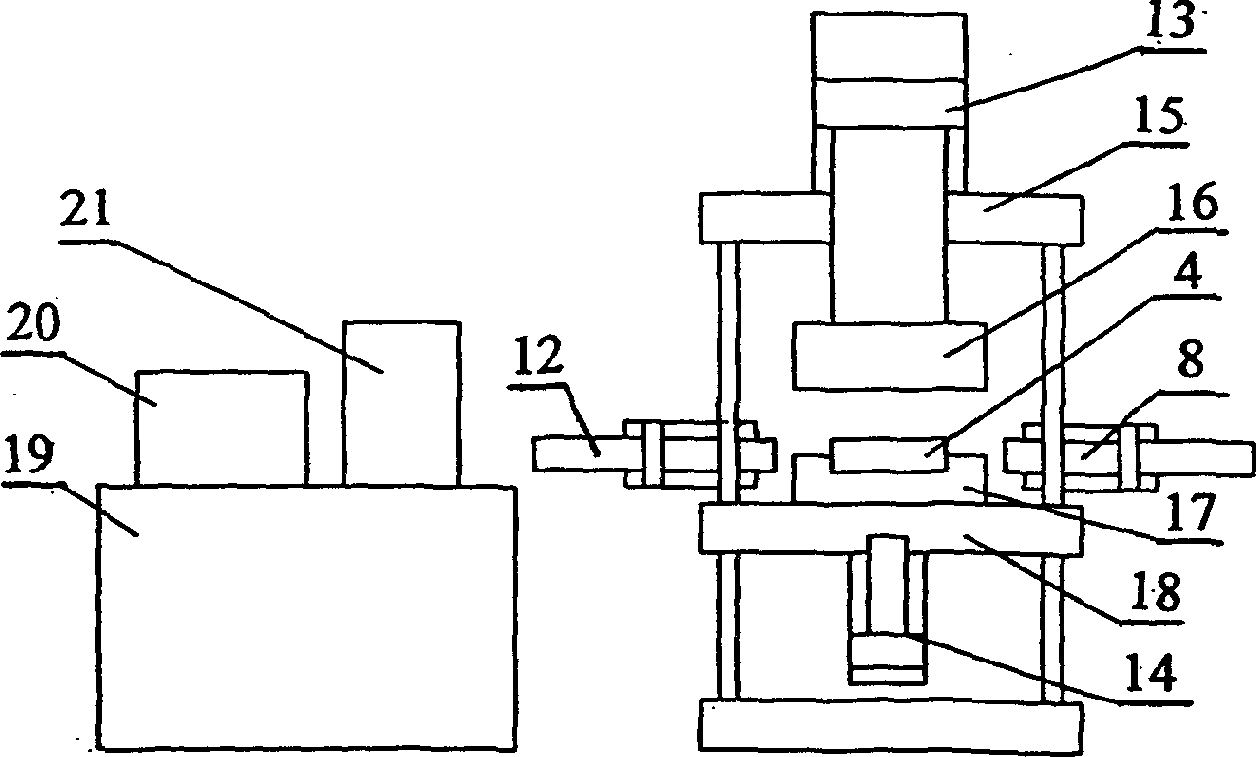

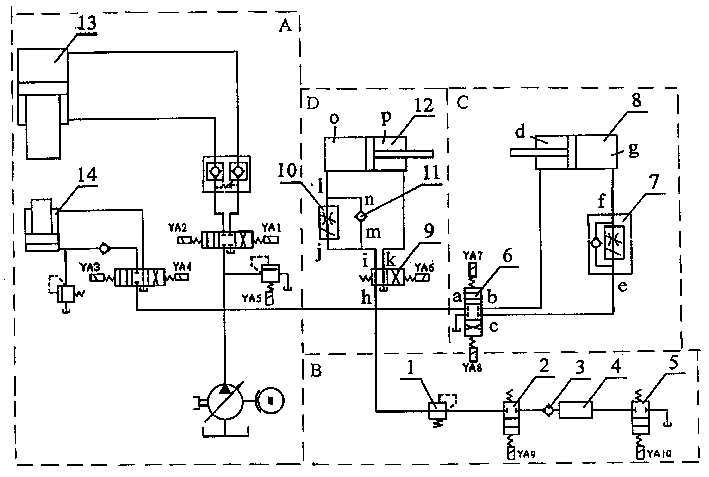

[0012] Such as figure 1 Shown is the schematic diagram of the system structure of the present invention. It includes the hydraulic control part A that makes the main cylinder 13 and the ejector cylinder 14 act, the hydraulic control part B for oil / water injection, the hydraulic control part C for the extrusion cylinder speed, the synchronous hydraulic control part D for the extrusion cylinders on both sides, and the extrusion cylinder speed The input ends of the hydraulic control part C and the synchronous hydraulic control part D of both extrusion cylinders are connected to the output end of the hydraulic pump of the hydraulic control part A which acts on the main cylinder and the ejector cylinder, and the input end of the hydraulic control part B for oil / water injection It is connected with the output end of the hydraulic pump of the hydraulic control part A or the output end of the saponification water pump of the main cylinder and the ejection cylinder.

[0013] However, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com