Process for purifying swainsonine by biofermentation

A technology of swainsonine and biological fermentation, which is applied in the field of bioengineering research and can solve the problems of high cost and low content of swainsonine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

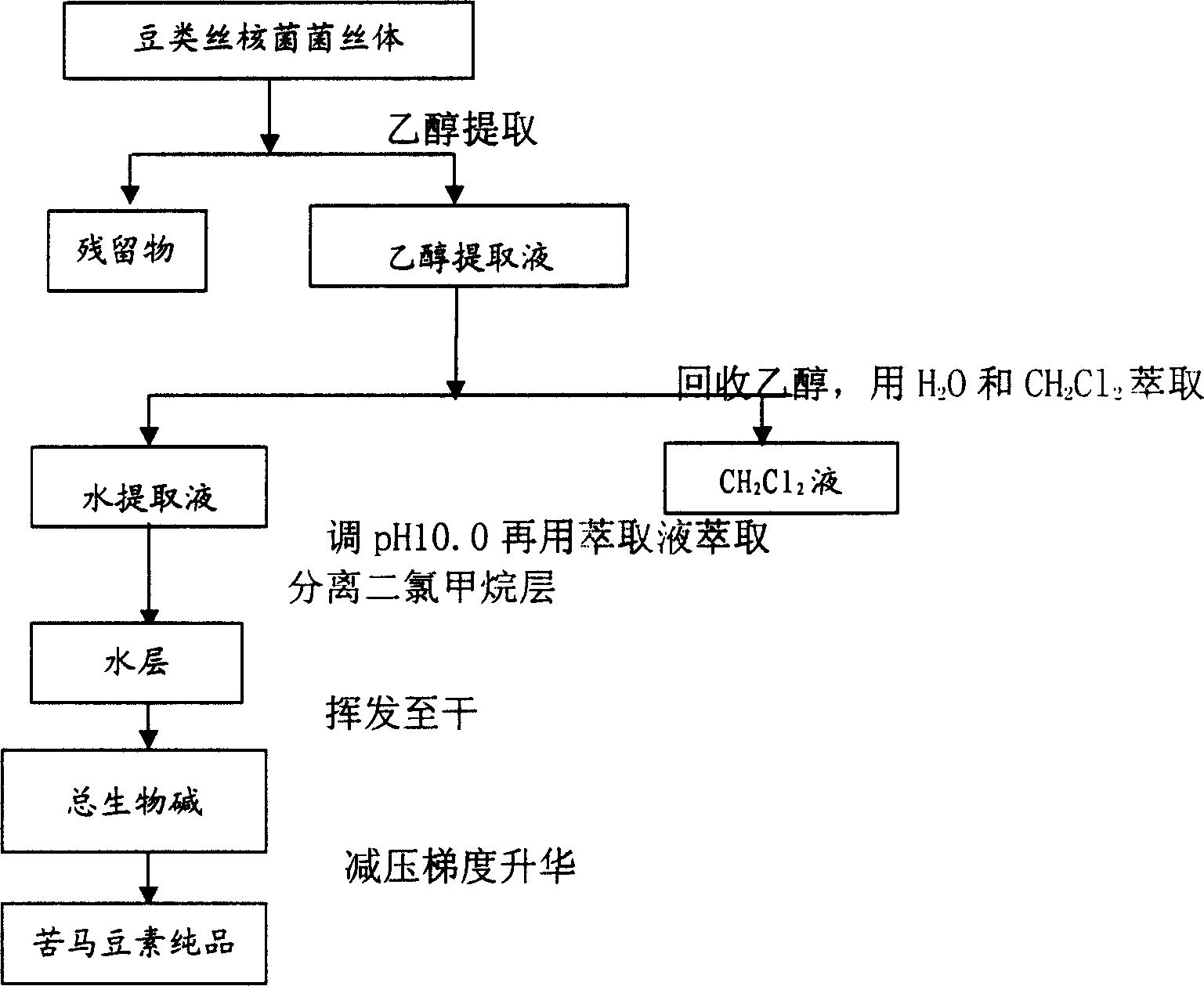

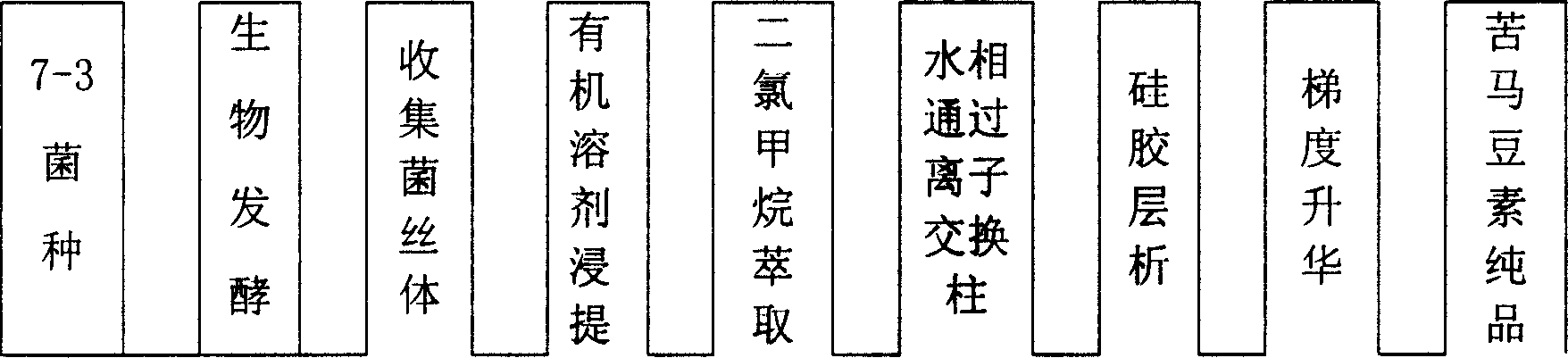

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: according to the technical scheme of the present invention, the process of purifying swainsonine is carried out as follows:

[0023] 1) Preservation of Rhizoctonia leguminosa 7-3: self-isolated Rhizoctonia leguminosa 7-3 PDA medium was inoculated, stored in a refrigerator at 4°C, and subcultured once every 20 days;

[0024] The formula of PDA medium consists of: peeled potato 200g, agar 15g, glucose 20g, water 1000ml;

[0025] 2) Inoculation, cultivation and collection of mycelium of Rhizoctonia leguminosa 7-3: In aseptic condition, inoculate strain 7-3 in Czapek's medium for biological fermentation, culture in aeration at 25°C for 2 weeks, and collect mycelia Body, dry, spare;

[0026] The formula of Czapek's medium consists of: 30g of sucrose, 3g of sodium nitrate, 1.3g of dipotassium hydrogen phosphate, 0.5g of magnesium sulfate, 0.5g of potassium chloride, 0.01g of ferrous sulfate, 3g of yeast extract, and 1000ml of water.

[0027] 3) Purification of...

Embodiment 2

[0033] Embodiment 2: according to the technical scheme of the present invention, the process of purifying swainsonine is carried out in the following steps:

[0034] 1) Preservation of Rhizoctonia leguminosa 7-3: self-isolated Rhizoctonia leguminosa 7-3 PDA medium was inoculated, stored in a refrigerator at 4°C, and subcultured once every 25 days;

[0035] The formula of PDA medium consists of: peeled potato 1000g, agar 75g, glucose 100g, water 5000ml;

[0036] 2) Inoculation, cultivation and collection of mycelium of Rhizoctonia leguminosa 7-3: in aseptic condition, inoculate strain 7-3 in Czapek's medium for biological fermentation, culture in aeration at 27°C for 2 weeks, and collect mycelia Body, dry, spare;

[0037] The formula of Czapek's medium is as follows: 150g of sucrose, 15g of sodium nitrate, 6.5g of dipotassium hydrogen phosphate, 2.5g of magnesium sulfate, 2.5g of potassium chloride, 0.05g of ferrous sulfate, 15g of yeast extract, and 5000ml of water.

[0038]...

Embodiment 3

[0044] Embodiment 3: according to the technical scheme of the present invention, the purification process of swainsonine is carried out in the following steps:

[0045] 1) Preservation of Rhizoctonia leguminosa 7-3: self-isolated Rhizoctonia leguminosa 7-3 PDA medium was inoculated, stored in a refrigerator at 4°C, and subcultured once every 20 to 30 days;

[0046] The formula of PDA medium consists of: 2000g of peeled potatoes, 150g of agar, 200g of glucose, and 10000ml of water;

[0047]2) Inoculation, cultivation and collection of mycelia of Rhizoctonia leguminosa 7-3: In aseptic condition, inoculate strain 7-3 in Czapek's medium for bio-fermentation, culture in aeration at 26°C for 2 weeks, and collect mycelia Body, dry, spare;

[0048] The formula of Czapek's medium is as follows: 300g of sucrose, 30g of sodium nitrate, 13g of dipotassium hydrogen phosphate, 5g of magnesium sulfate, 5g of potassium chloride, 0.1g of ferrous sulfate, 30g of yeast extract, and 10000ml of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com