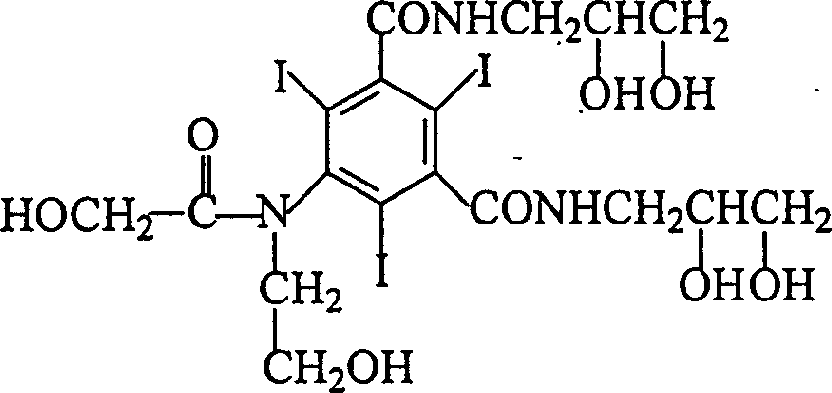

Method for purifying ioversol

A purification method, the technology of ioversol, which is applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems that ioversol cannot be completely purified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 3L three-necked flask equipped with an electric stirrer and a reflux condenser, the crude ioversol (45g) was added to n-butanol (2250mL), and the temperature was gradually raised to reflux under stirring, and refluxed for 5 hours, then filtered the white The suspension was washed with hot n-butanol (3×15 mL) on the filter and dried in vacuo to obtain 27.5 g of ioversol. HPLC analysis (water / acetonitrile, C 8 column). The results are shown in Table 1.

[0023] Dissolve ioversol (27.5g) obtained in the first recrystallization above in water (150mL), evaporate to dryness under reduced pressure and add n-butanol (1375mL) to carry out the second recrystallization, the operation steps are the same as the first recrystallization Crystallization, to get ioversol 19.3g, carry out HPLC analysis (water / acetonitrile, C 8 column). The results are shown in Table 1.

[0024] the peak

Embodiment 2

[0026] In a 1L three-neck flask equipped with an electric stirrer and a reflux condenser, the ioversol crude product (45g) was added to a mixture of 2-methoxyethanol (135mL) and isopropanol (540mL), and the temperature was gradually raised to Keep the temperature at 100°C for 5 hours, then filter the white suspension while hot, wash the crystals with hot isopropanol (3×15 mL) on the filter, and dry in vacuo to obtain 29.2 g of ioversol. HPLC analysis (water / acetonitrile, C 8 column). The results are shown in Table 2.

[0027] Dissolve ioversol (29.2g) obtained in the first recrystallization above in water (150mL), evaporate to dryness under reduced pressure, add 2-methoxyethanol (88mL) and isopropanol (350mL), and carry out the second Recrystallization, operation steps are the same as first time recrystallization, get ioversol 20.8g, carry out HPLC analysis (water / acetonitrile, C 8 column). The results are shown in Table 2.

[0028] the peak

Embodiment 3

[0030] In a 1L three-necked flask equipped with an electric stirrer and a reflux condenser, add crude ioversol (45 g) into a mixture of 2-methoxyethanol (90 mL) and n-butanol (600 mL), and gradually heat up to 100 °C under stirring. ℃, keep the temperature constant for 5 hours, then filter the white suspension while hot, wash the crystals with hot n-butanol (3×15 mL) on the filter, and dry in vacuo to obtain 31.5 g of ioversol. HPLC analysis (water / acetonitrile, C 8 column). The results are shown in Table 3.

[0031] Dissolve ioversol (31.5g) obtained in the first recrystallization above in water (150mL), evaporate to dryness under reduced pressure, add 2-methoxyethanol (63mL) and n-butanol (420mL), carry out the second recrystallization Crystallization, the operating steps are the same as the first recrystallization, to get ioversol 25g, carry out HPLC analysis (water / acetonitrile, C 8 column). The results are shown in Table 3.

[0032] the peak

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com