Apparatus and method for treating titanium tetrachloride slurry containing vanadium

A technology of titanium tetrachloride and treatment method, which is applied in the field of halide vapor phase oxidation to produce rutile titanium dioxide, can solve the problems of unresolved mud addition technology, high operating cost, hindering production, etc., so as to save money and energy, The effect of reducing costs and reducing operating expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

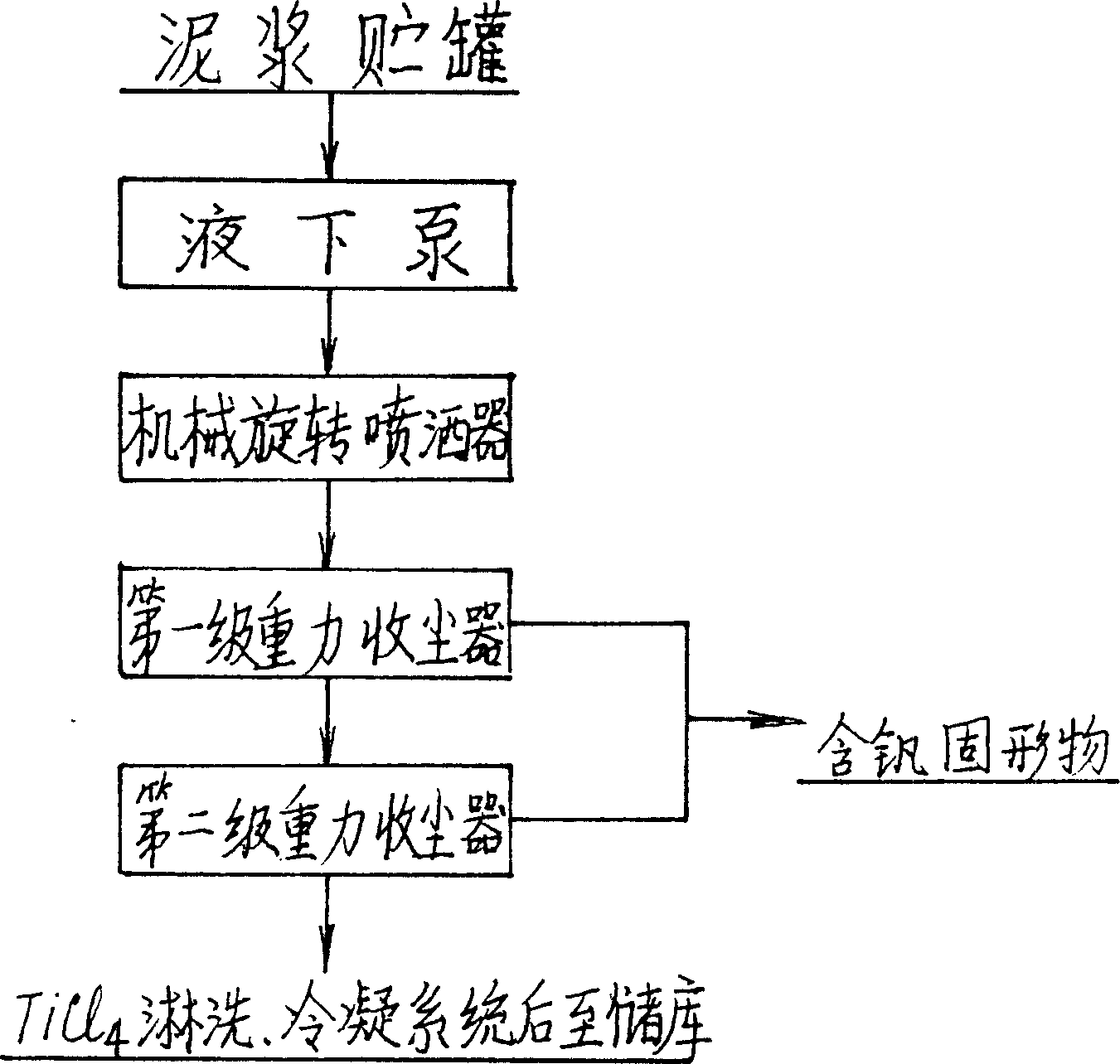

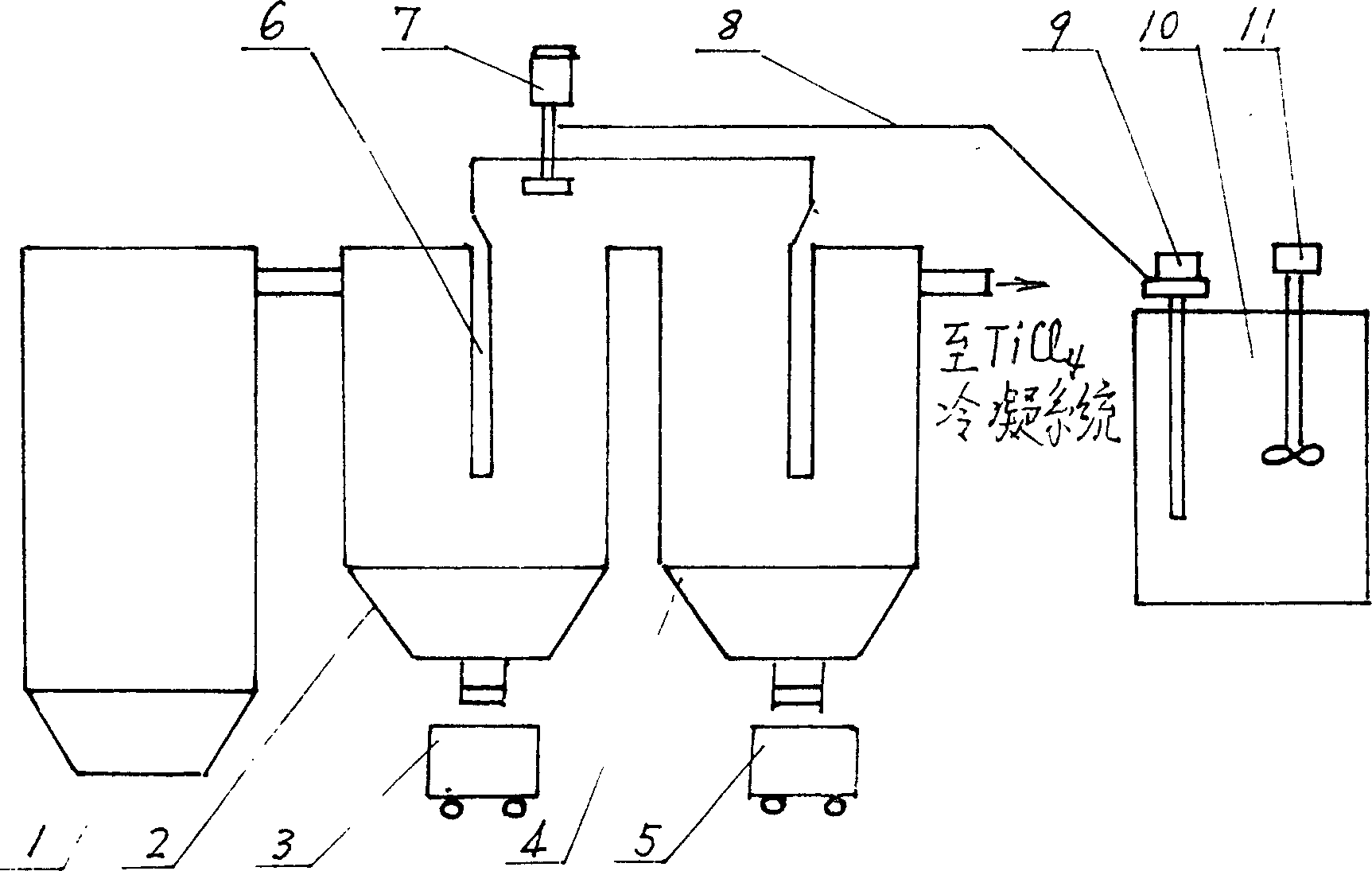

[0012] A method for treating vanadium-containing titanium tetrachloride mud, which is to use the submerged pump 9 located in the vanadium-containing titanium tetrachloride mud storage tank 10 to send the mud through the pipeline 8 to the first stage of gravity dust collection in the chlorination system In the mechanical rotary sprinkler 7 at the top of the device 2, the mud is sprayed into the first-stage gravity dust collector 2 with a diameter of 5 m by a nozzle (210 mm in diameter) rotating at a speed of 31.2 m / min at a speed of 1440 rpm. Countercurrent heat exchange with the 450°C high-temperature mixed gas discharged from the chlorination furnace 1, the titanium tetrachloride droplets in the mud are gasified, and enter the second-stage gravity dust collector 4 with the mixed gas, and most of the vanadium-containing solids are in the Under the action of gravity, it settles into the ash box 3 at the bottom of the gravity dust collector 2, and is sent to the flushing system r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com