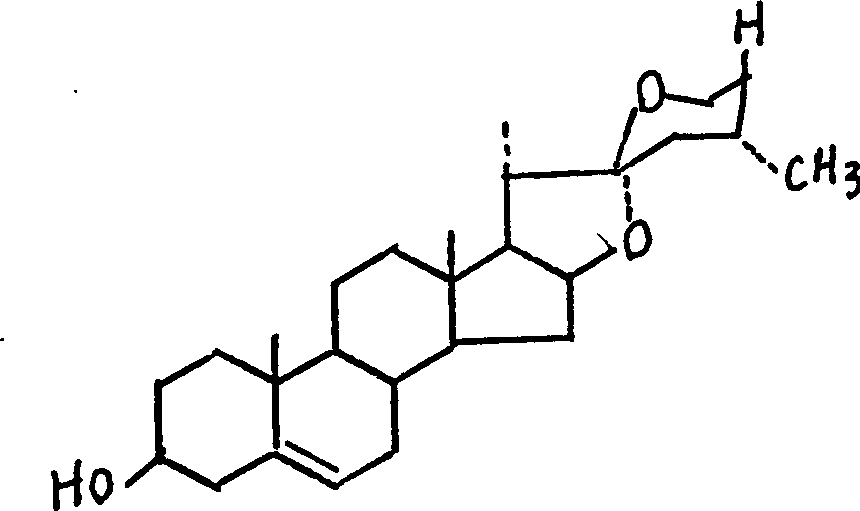

Application method of super critical fluid extracting device in yam saponin production

A supercritical fluid and extraction device technology, which is applied in the general preparation field of steroids, can solve problems such as unacceptable, unable to eliminate the large volume of raw materials and small volume of extraction equipment, which is contrary to the enterprise's pursuit of profit maximization, and achieves a high yield. Improvement, strong market demand, and the effect of reducing pharmaceutical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

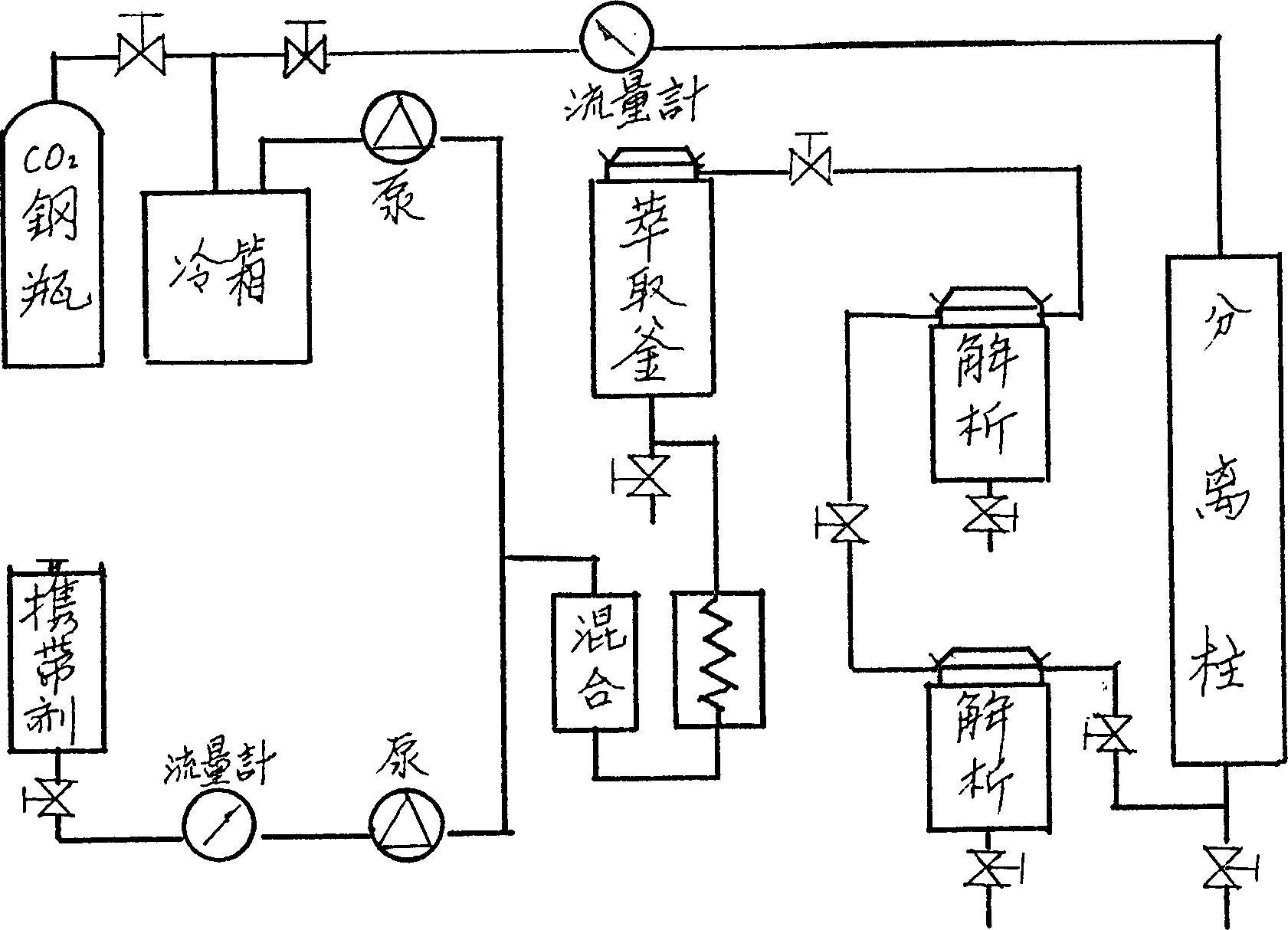

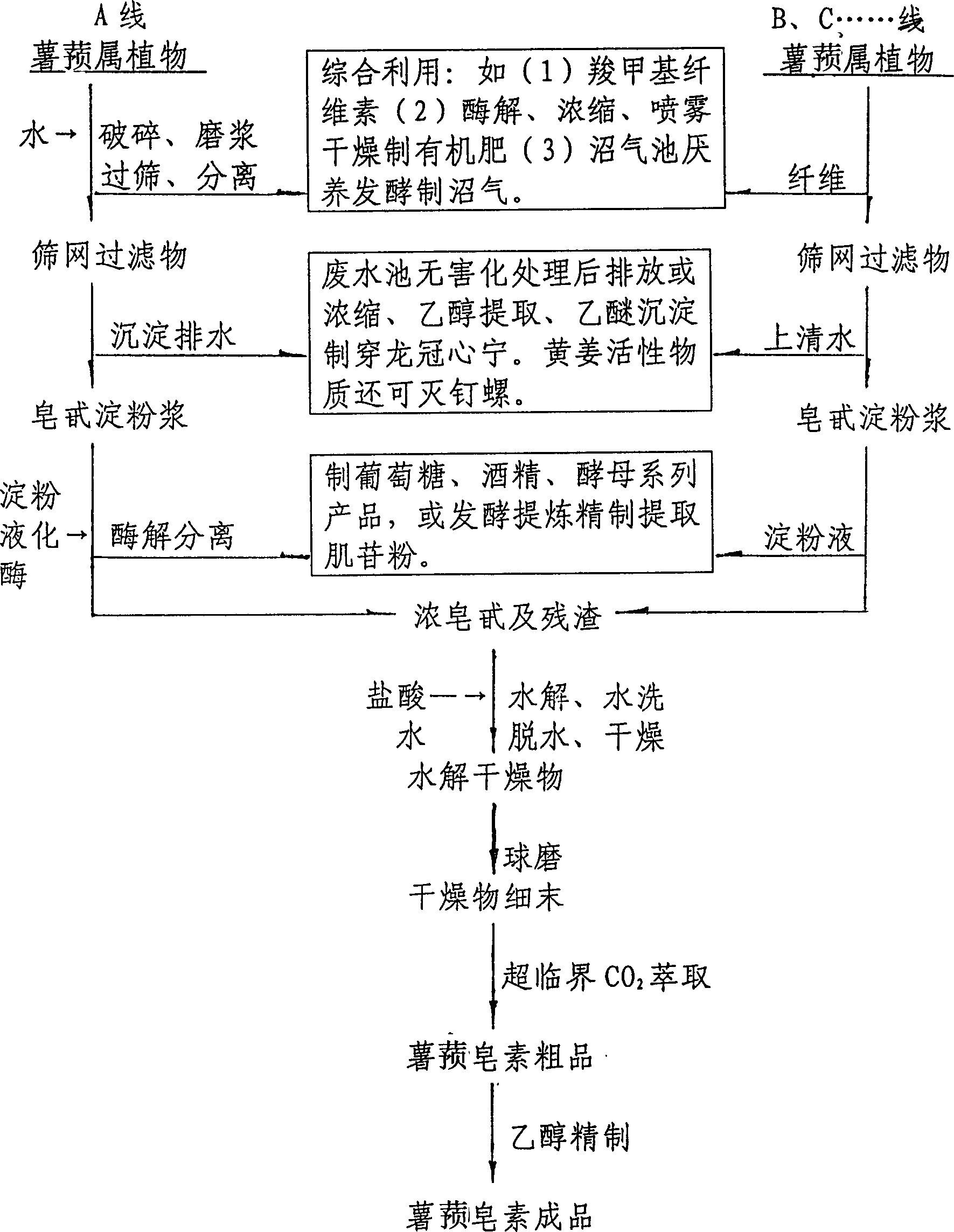

[0033] The following uses 500L / 40Mpa one-extraction-two-separation cycle supercritical CO 2 Take the extraction device as an example:

[0034] The volume of the extraction kettle is 500L, which can be filled with 300kg of fine powder of hydrolyzate with high content of diosgenin, which is equivalent to 3000kg of dry hydrolyzate of dioscin. After charging is complete, open the CO 2 Put the gas bottle into the cold air tank, turn on the air conditioner to cool the gas tank, open the steam valve to heat the extraction kettle, desorption kettle 1, 2 and separation column respectively, and adjust the set temperature of each container through the steam inlet and outlet valves, that is The temperature of the extraction kettle is 75°C, the temperature of the desorption kettle 1 is 65°C, the temperature of the desorption kettle 2 is 50°C, and the temperature of the separation column is 65°C. After meeting the above temperature setting conditions, start the air high-pressure pump to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com