Method for processing reduced fluorine content brick tea

A processing method and technology of fluorine content, applied in tea treatment before extraction, etc., can solve problems such as failure to apply, and achieve obvious effects of reducing fluoride, significant economic benefits, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

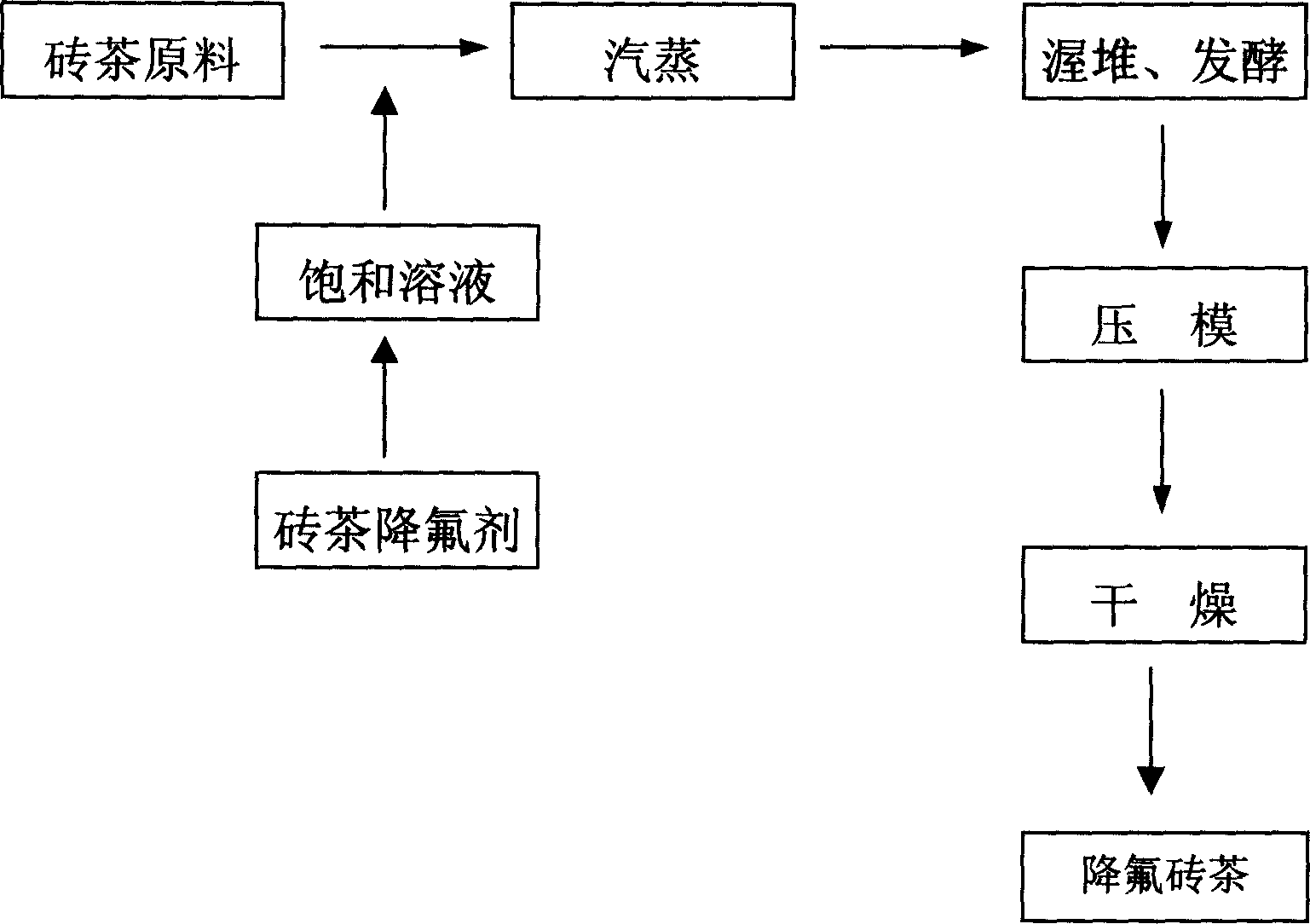

Method used

Image

Examples

Embodiment 1

[0019] Fluoride-reducing effect of fluoride-reducing agent and its influence on tea quality components

[0020] The defluoridation agent is prepared into a solution with a concentration of 1%, which is uniformly added to the brick tea raw materials according to the addition amount of 0, 5, 10, 15, 20, and 25 g / kg respectively, and dried in an oven at 80°C until it is fully dry. Each treatment was repeated 3 times, and the content of water-soluble fluorine and its quality components in each tea sample before and after treatment were determined. The results are as follows:

[0021] Table 1 Fluoride-reducing effect of defluoridation agent and its influence on tea quality components

[0022] Added amount Water-soluble fluoride Fluoride reduction rate Tea polyphenols Amino acids Caffeine

[0023] (g / kg) (mg / kg dry tea) (%) (%) (%) (%)

[0024] 0 481.72 10.79 0.47 1.82

[0025] 5 196.91 59.12 10.01 0.42 1.76

[0026] 10 175.63 63.54 9.74 0.44 1.72

[0027] 15 161.95 66.3...

Embodiment 2

[0032] Processing and production of Jianguo Kang brick tea

[0033] According to the processing technology of the present invention, the raw materials for producing Kangzhuan tea: Jinyu tea and pruning tea are respectively subjected to defluoridation treatment. In 500 kg of Jinyu tea and 500 kg of trimming tea, the brick tea defluoridation agent-calcium dihydrogen phosphate was evenly added in a proportion of 0.5%, and heated by steam, fermented for 2 days, dried, winnowed, and pressed to produce 980 kg of Norflucon bricks. According to the measurement by the Tea Quality Supervision, Inspection and Testing Center of the Ministry of Agriculture, the sensory quality of the Jiangfu Kang brick tea added with the brick tea defluoridation agent is normal, and its water-soluble fluorine content is 300.7mg / kg, which is 44.35% lower than that of the control Kang brick 540.3mg / kg .

Embodiment 3

[0035] Processing and production of fluorine-reduced Fu brick tea:

[0036] According to the processing technology of the present invention, in 1 ton of raw materials of Fuzhuan brick tea, the proportion of 0.5% is uniformly added into the Fuzhuan brick tea defluoridation agent-the mixture of calcium dihydrogen phosphate and calcium chloride, and steam is passed through to heat and ferment for 4 hours , pressed and dried to make fluorine-reduced Fu brick tea. The sensory quality of the defluoridated brick tea treated with brick tea defluoridation agent was normal, and its water-soluble fluorine content was reduced by 40.67% compared with the control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com