Closed pipeline type photosynthetic reactor

A photosynthetic reactor and pipeline-type technology, which is applied in the field of reactors for cultivating microalgae or other photosynthetic organisms, can solve the problems of cultivation scale expansion, scale-limited enlargement and industrial application, algae cell inhibition, etc., to achieve the reduction of dissolved oxygen Concentration, conducive to industrial application, increase the effect of gas-liquid exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

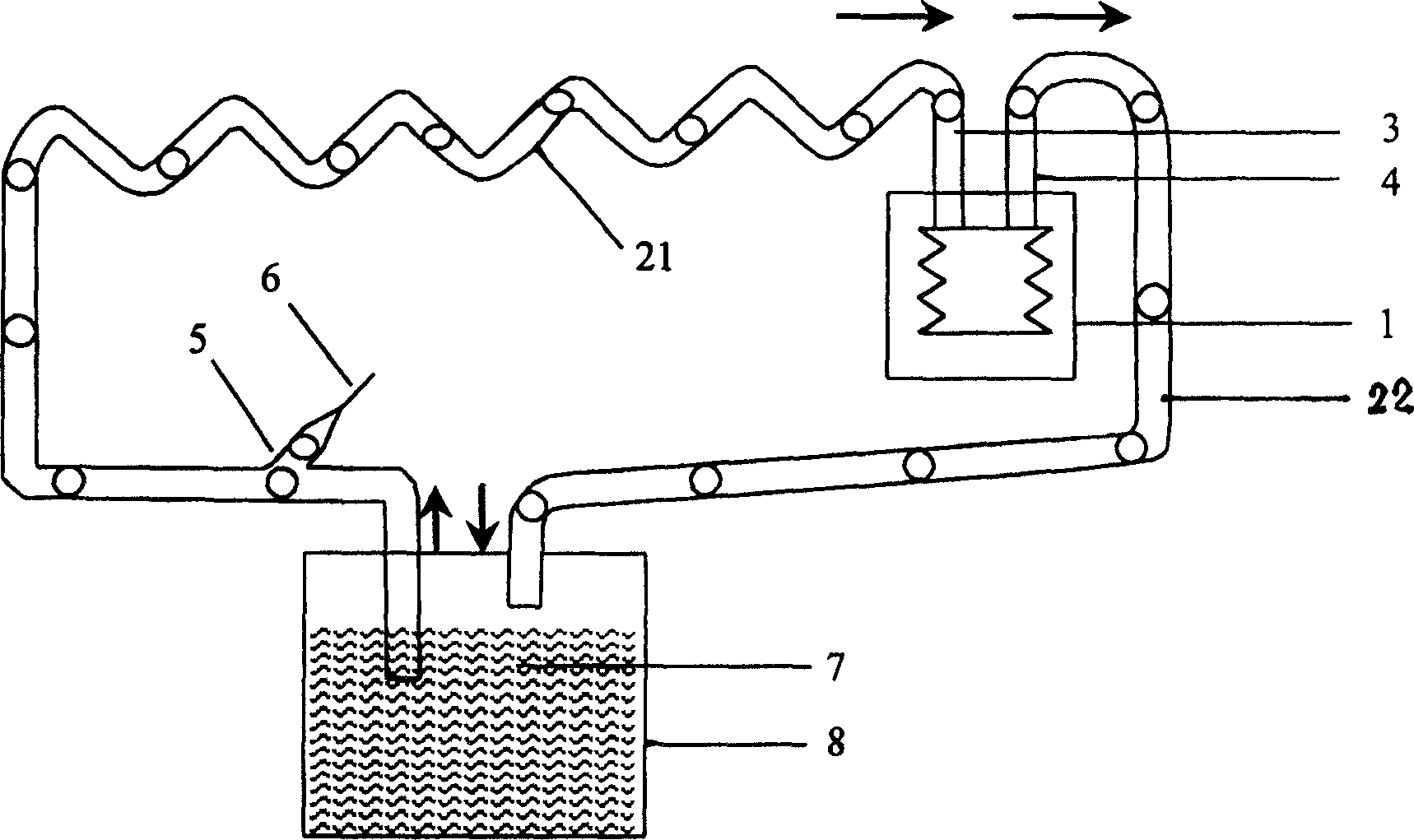

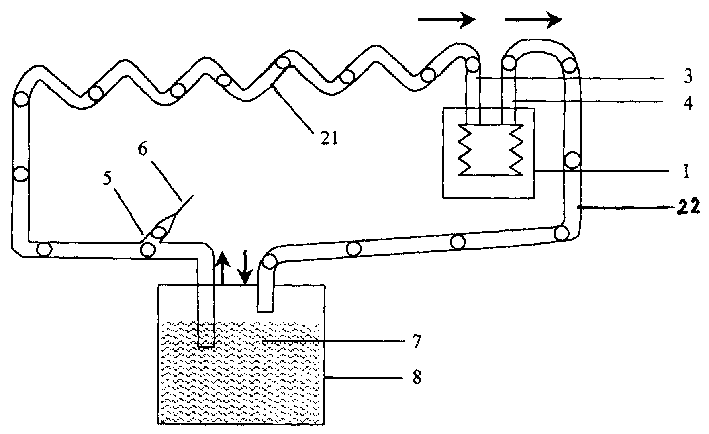

[0012] The structural details of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0013] Such as figure 1 Shown, this photosynthetic reactor uses airbag pump 1 as the power system of photosynthetic reactor, is that the plastic pipe of 6 millimeters is used as the photoreaction pipe with diameter, comprises suction pipe 21 and return pipe 22, the input end of suction pipe 21 and the backflow The output end of the pipe 22 is inserted into the algae liquid storage bottle 8, the output end of the suction pipe 21 is connected to the liquid inlet 3 of the airbag pump, and the liquid outlet 4 of the airbag pump is connected to the input end of the return pipe to form algae Liquid circulation circuit, in the suction pipe 21 up to 10 meters near the algae liquid storage bottle position, connect a side branch glass capillary 6 as the ventilating side pipe through the trident pipe 5. Add 1 liter of concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com