Chute-type furnace roof distributor driven via self-centering combined link rod

A distributor and chute technology, which is applied in the field of blast furnace distributing devices, can solve the problems of affecting the quality and life, popularizing and applying, shortening the life, and aggravating the wear of the supporting ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

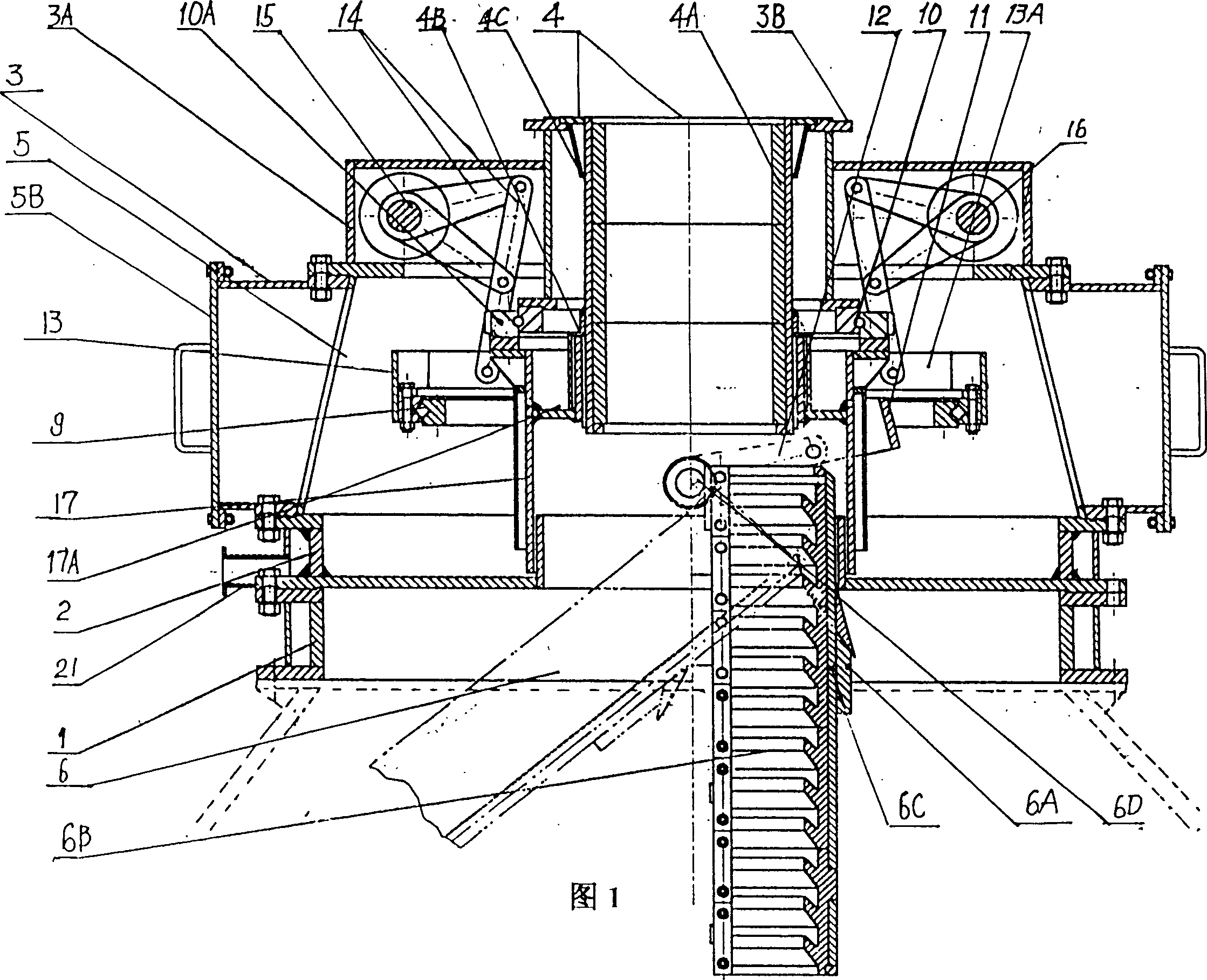

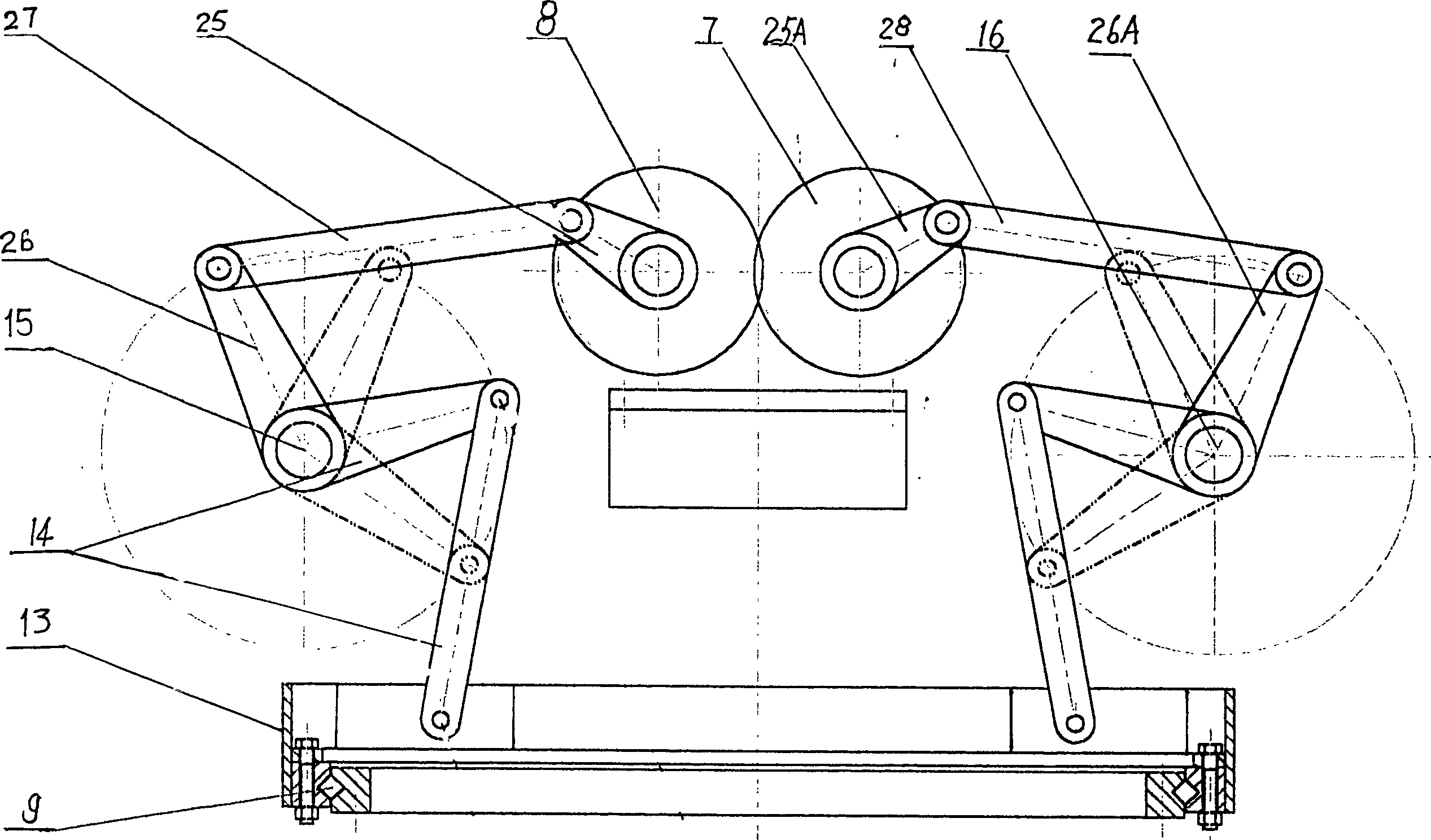

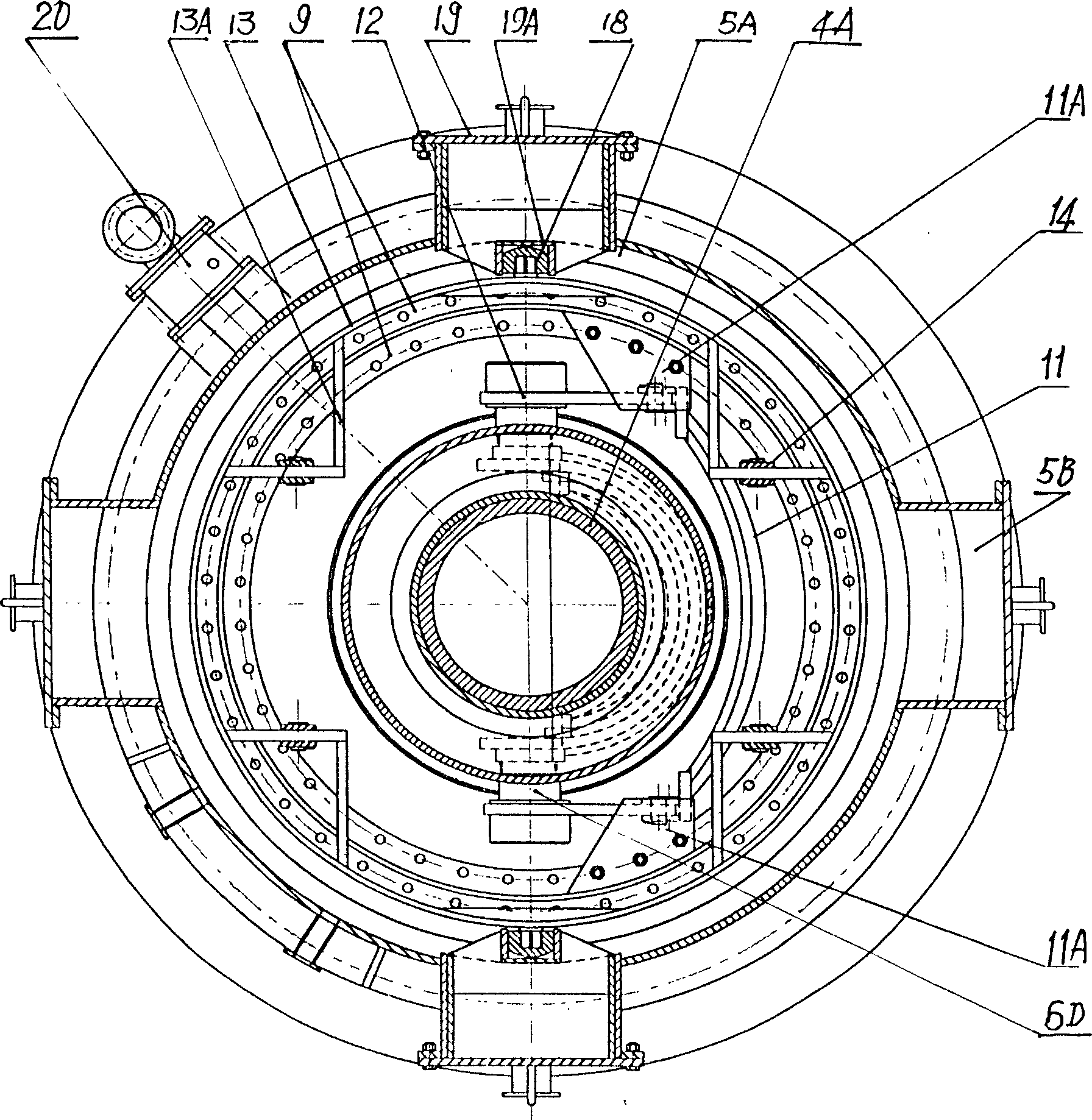

[0015] What the α angle transmission mechanism adopted in this device is by two shafts (15, 16) with opposite directions of rotation and four crank connecting rods (14) groups that are connected on the shaft and are symmetrically distributed. These four crank connecting rods are evenly connected on the outer support ring 13 of the upper bearing large support ring 9 . In this way, along with the synchronous rotation of the axles (15, 16), the four crank linkages form a synchronous self-centering grabbing mechanism. Grab and carry middle and lower bearing bearing support ring 9 and move up and down, but do not hinder the rotation of inner sleeve.

[0016] As long as the shafts 15 and 16 are synchronously and reversely rotated, the α-angle rotation mechanism can smoothly transmit the rotational torque to the symmetrical semi Shaft 6D, so that the chute can be driven by 6D to swing at an angle of α between 0° and 90°.

[0017] One of the keys of the above transmission is to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com