Thin-combustion, port-sequence-injection, fully electric-controlled diesel/natural gas electronic control system for dual-fuel engine

A dual-fuel engine and electronic control system technology, applied in engine control, fuel injection control, machine/engine, etc., can solve the problems of inaccurate control of oil volume, scavenging short circuit, high emission, etc., and achieve high anti-interference ability and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

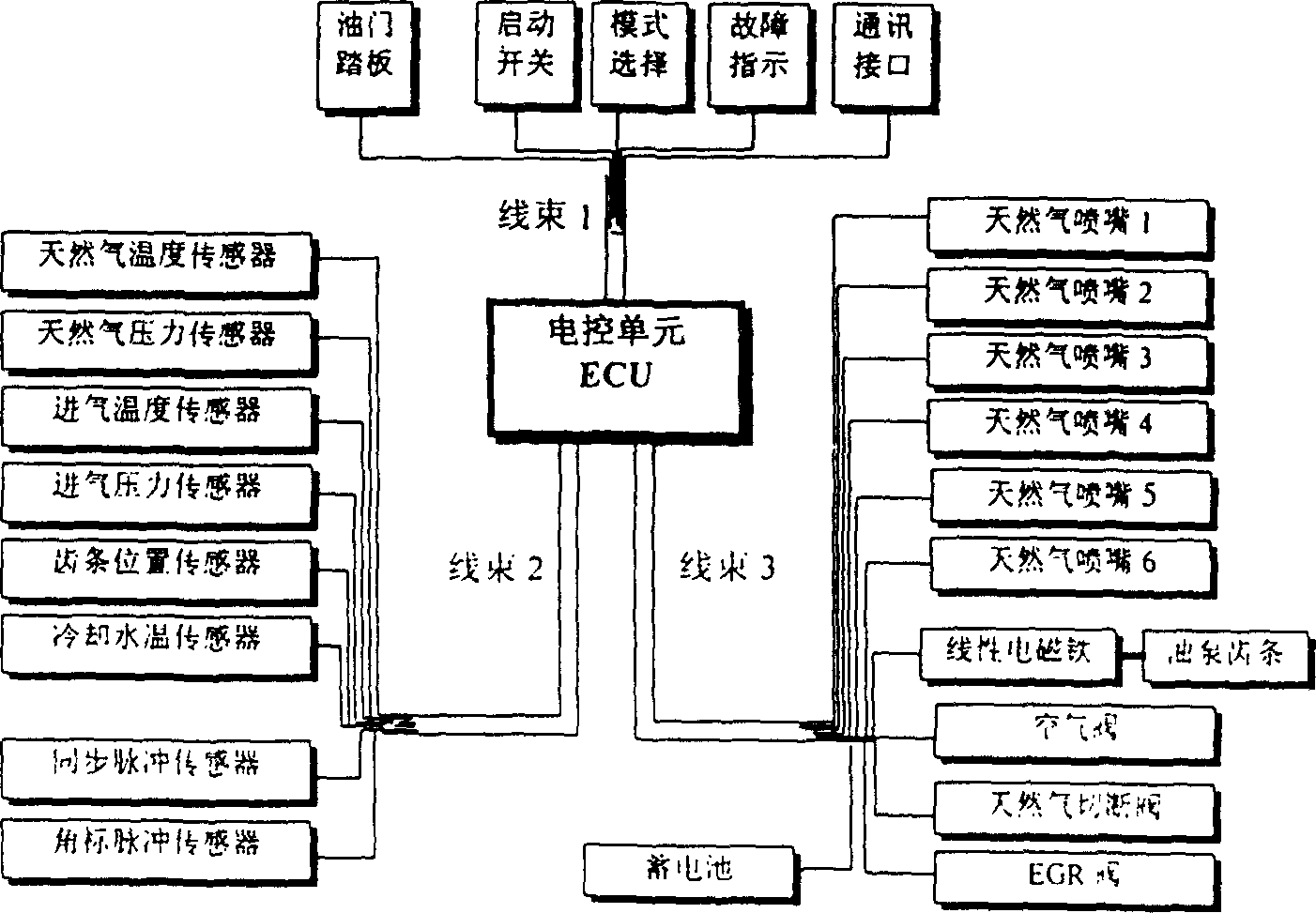

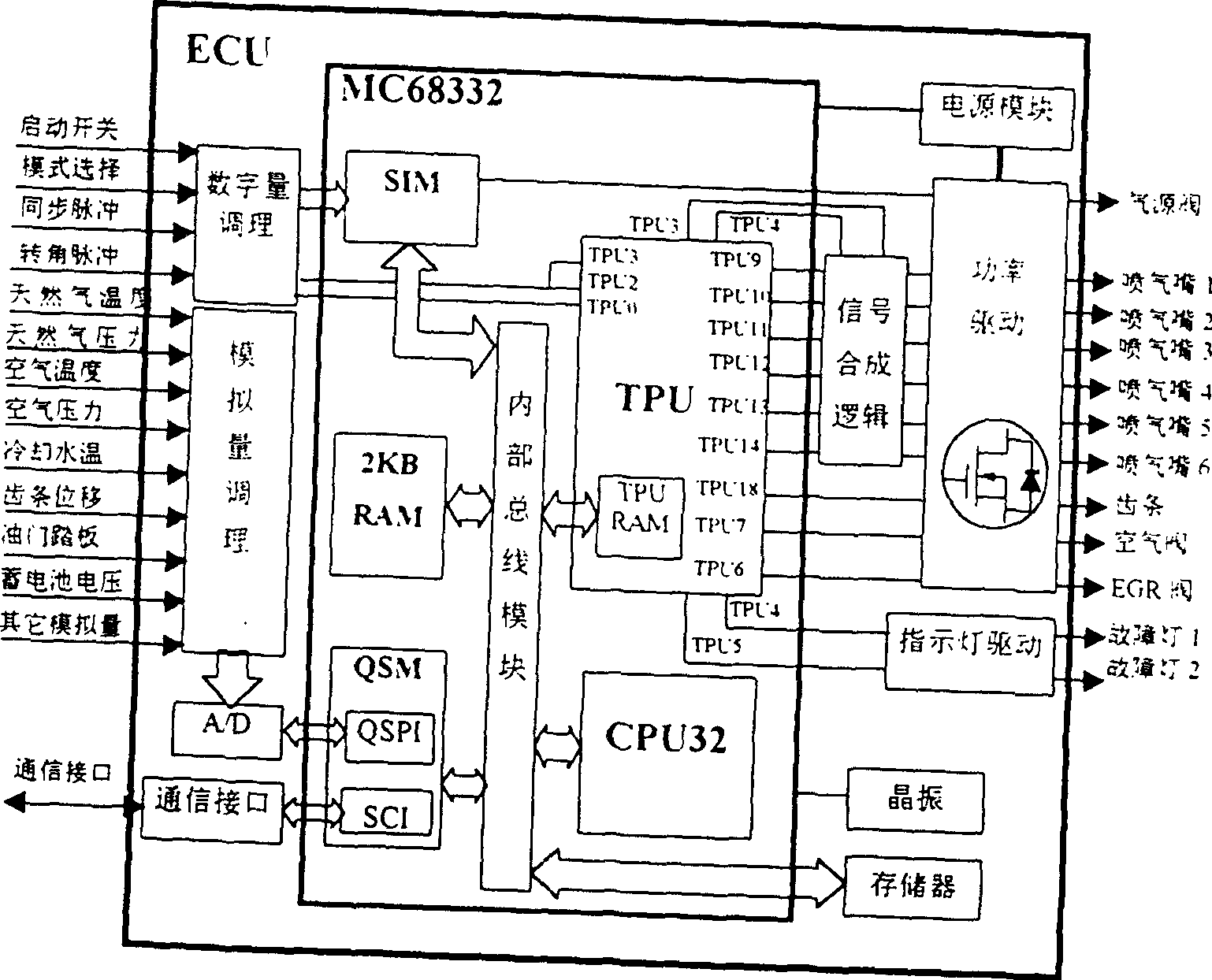

[0014] The electronic control system in the present invention can realize engine working condition judgment (starting, idle speed, acceleration, deceleration, overspeed working condition), working mode selection (pure diesel oil, dual-fuel operation), MAP correction (natural gas injection amount, diesel injection amount) and troubleshooting. When the engine is running, the electronic control unit first judges the working condition according to the cooling water temperature, oil temperature, pressure, engine speed, and accelerator pedal position, and then selects the working mode according to the working condition to control the operation of the MAP. In order to ensure that the engine works under the optimal excess air coefficient stored in MAP, the electronic control unit can correct the injection amount of natural gas, the number of cylinders stopped, and diesel injection in real time according to the actual conditions of engine operation (intake temperature, pressure, natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com