Activation apparatus and process for continuously preparing adsorbing agent of natural gas

A technology of reaction equipment and adsorbent, which is applied to high-temperature activation equipment and its process field, can solve the problems of lack of large-scale continuous preparation means, difficulty in meeting industrialized production, and difficulty in continuous production process in preparation technology, so as to achieve strong continuity and expand production. Scale, the effect of preventing strong corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] The raw materials used in the preparation of the natural gas adsorbent described in the present invention and their component distribution ratios are based on the contents of a "microporous carbonaceous adsorbent and its preparation method" disclosed in the prior art (application number: 01141565.7) based on. It uses petroleum coke, lignin or walnut shells as raw materials and potassium hydroxide as an activator.

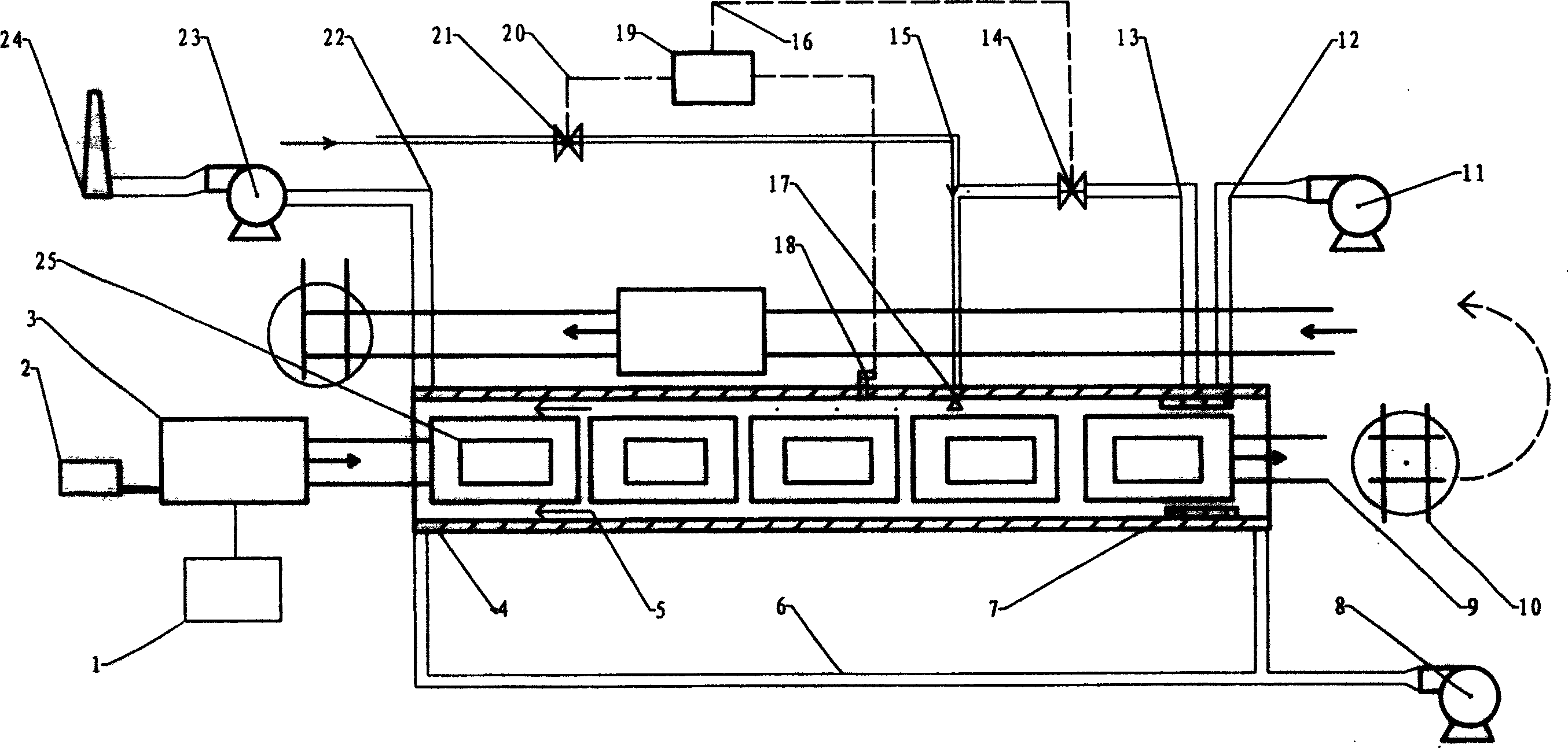

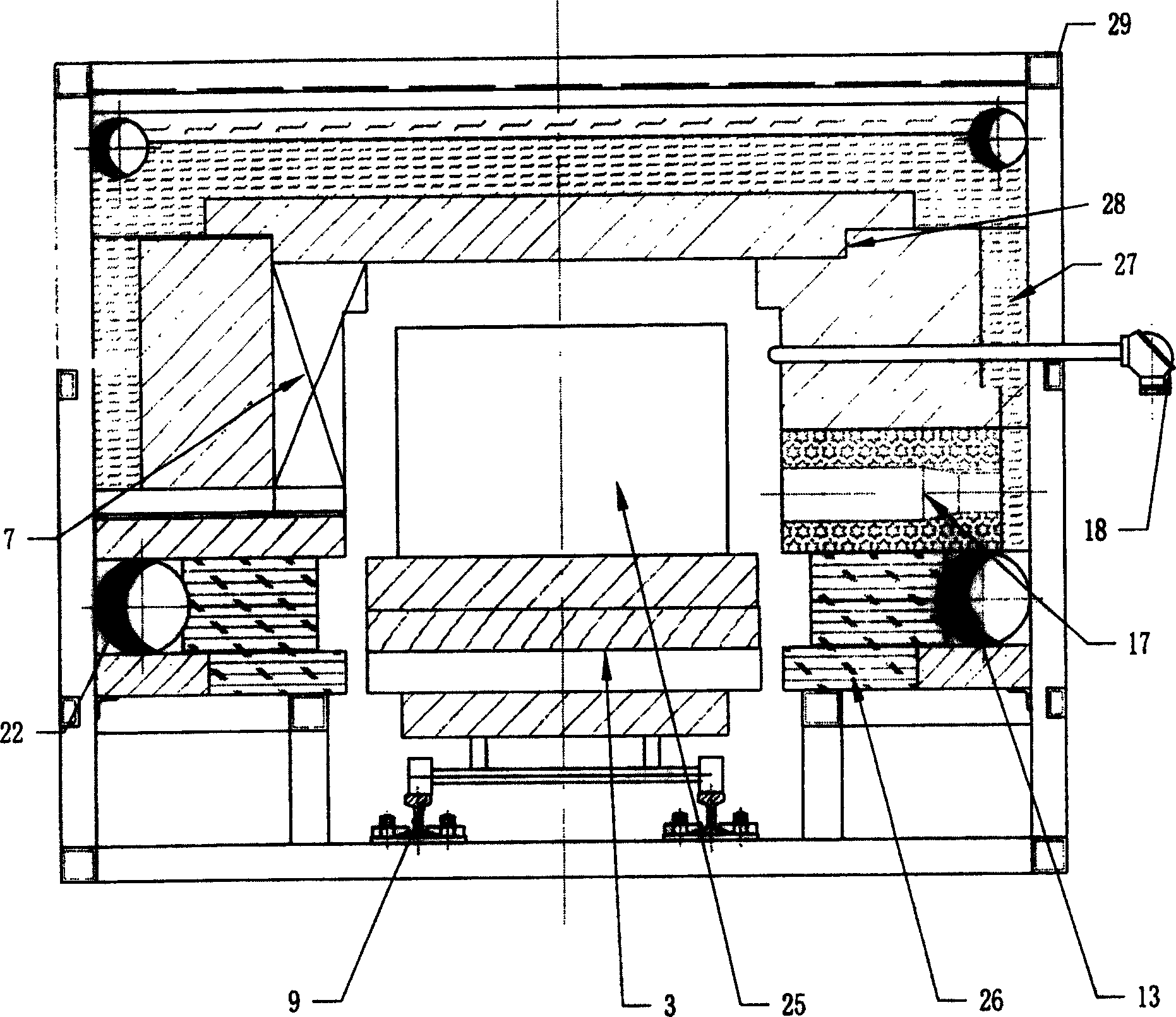

[0029] The activation reaction equipment of the present invention is mainly composed of the following five parts: a reaction kiln body, a combustion system, a temperature control system, a flue gas system and a raw material feeding system. (Such as figure 1 , figure 2 shown).

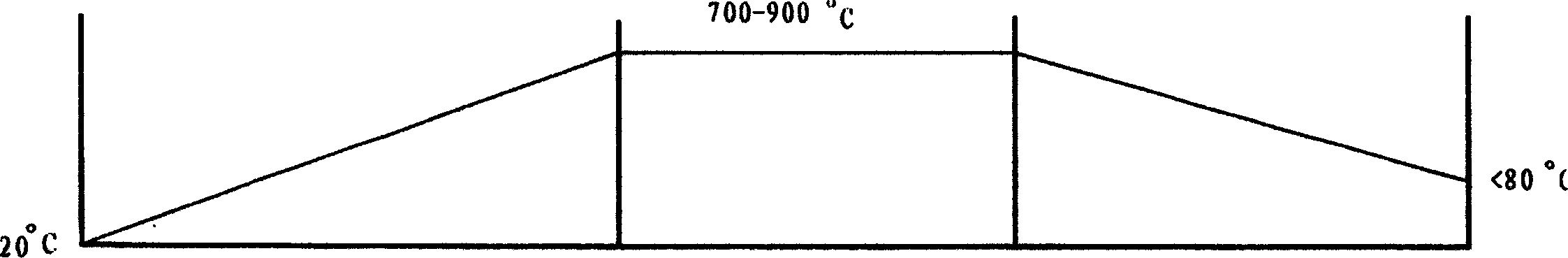

[0030] (1) Kiln body: the kiln body 4 includes three parts: a preheating section, a constant temperature section and a cooling section. In order to improve the heat utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com