Photomultiplier and radiation sensor

A technology for photomultiplier tubes and a manufacturing method, which are applied in the directions of electron multiplier tubes, measuring devices, detailed information of electron multipliers, etc., and can solve problems such as obstacles to the use of photomultiplier tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

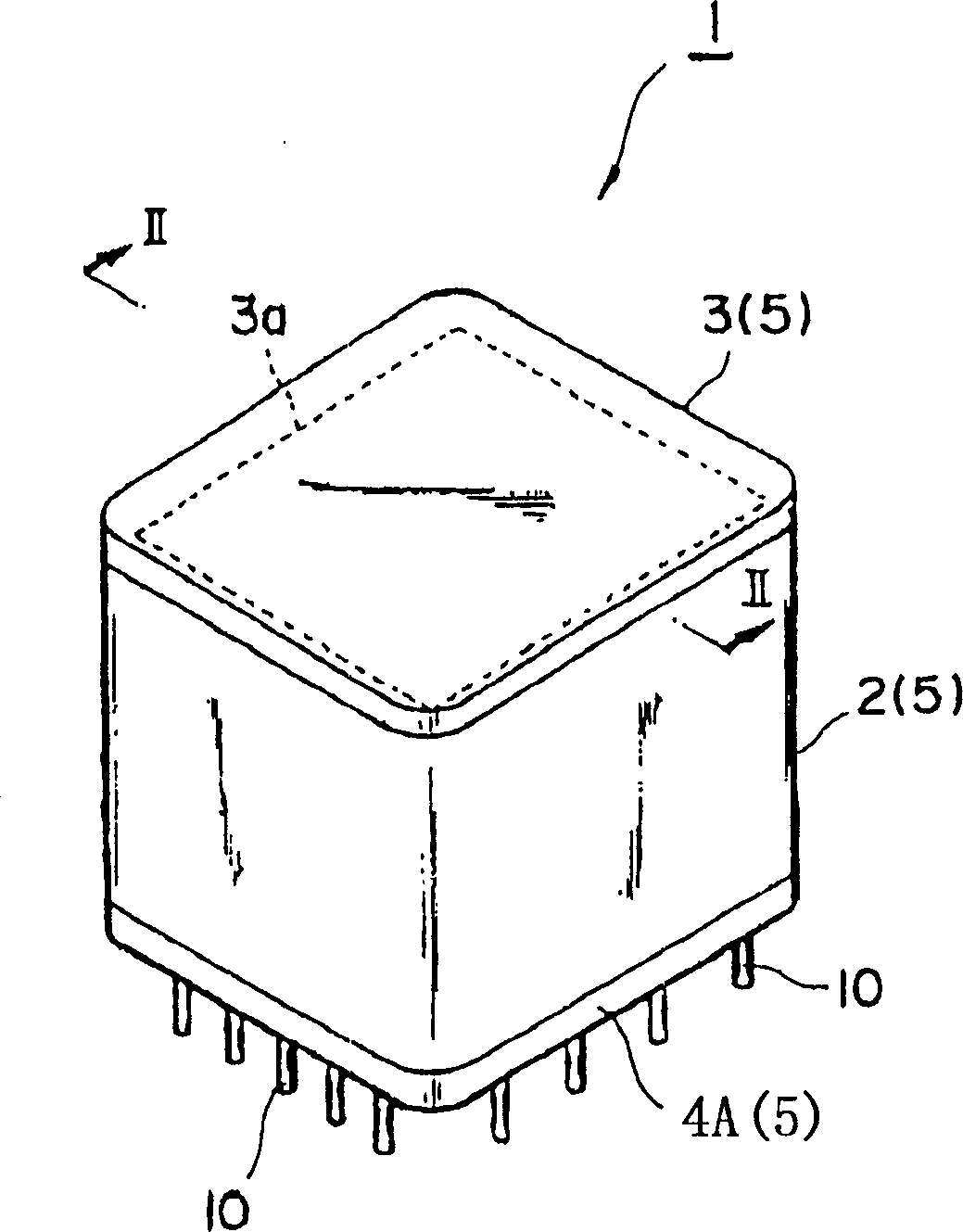

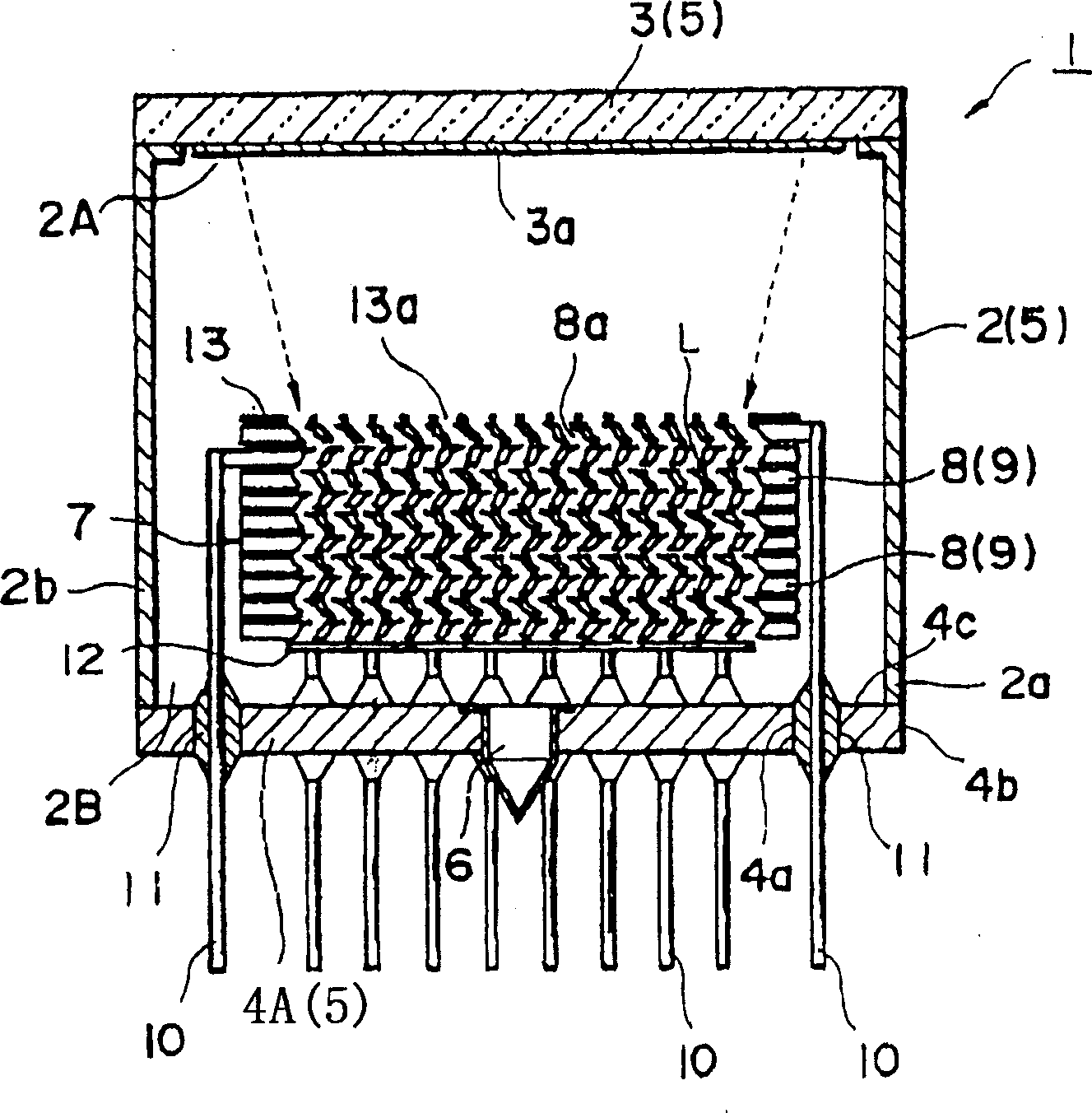

[0041] below, with Figure 1 The ideal embodiment of the photomultiplier tube of the present invention will be described in detail.

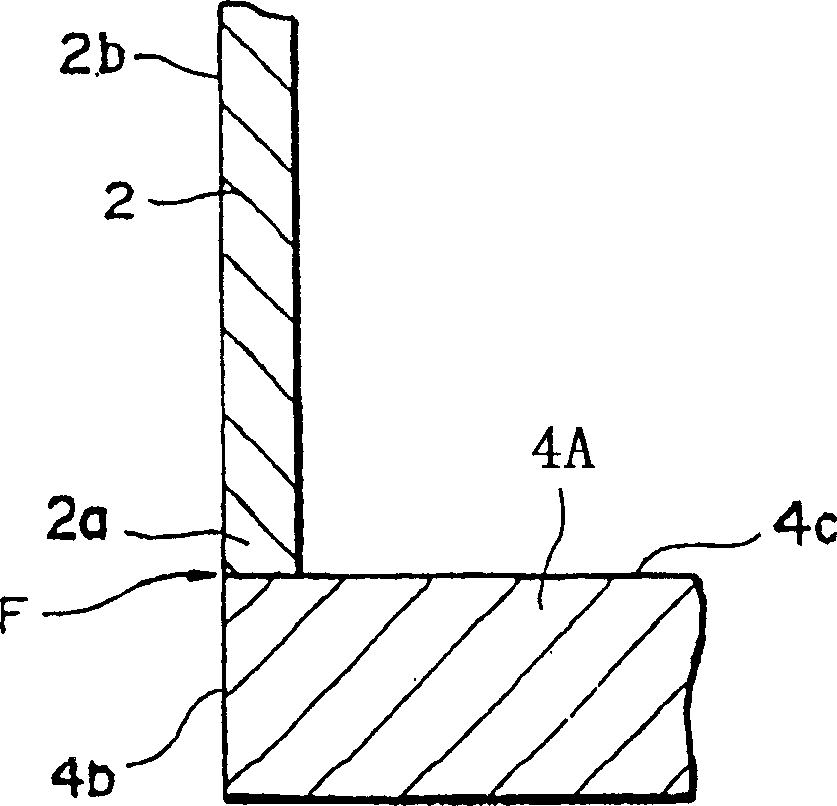

[0042] Fig. 1 is a perspective view showing a photomultiplier tube according to a first embodiment of the present invention, and Fig. 2 is a cross-sectional view of Fig. 1 . The photomultiplier tube 1 shown in these drawings has a side tube 2 made of metal (for example, made of Kovar (Kovar) iron-nickel-cobalt alloy or stainless steel) approximately in the shape of a square column, and the opening on one side of the side tube 2 is A light-receiving panel 3 made of glass is welded and fixed on the end 2A. On the inner surface of the light-receiving panel 3, a photoelectric surface 3a for converting light into electrons is formed. The antimony deposited on the surface reacts to form. In addition, a lever plate 4A made of metal (for example, made of Kovar metal or stainless steel) is welded and fixed to the opening end 2B of the side pipe 2 . Thu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com