Cationic coating composition

A cationic and composition technology, applied in the field of cationic coating composition, can solve the problems of incompatibility, not very effective performance, reduced corrosion resistance of coating film and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

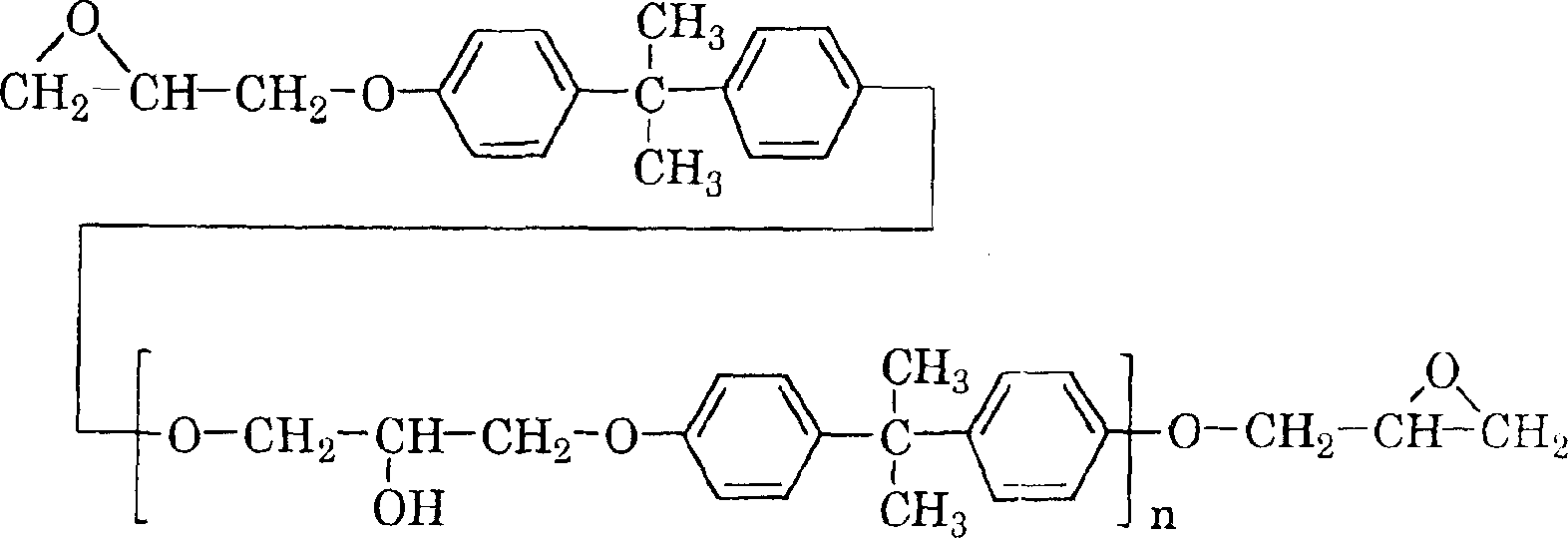

Method used

Image

Examples

preparation Embodiment 1

[0087] Preparation Example 1: Preparation of Xylene-Formaldehyde Resin 1

[0088] In a separable flask with a capacity of 2 liters of thermometer, reflux condenser and stirrer, 240g of 50% formaldehyde solution, 55g of phenol, 101g of 98% industrial sulfuric acid and 212g of m-xylene were charged at 84 It was made to react at 88 degreeC for 4 hours. After the reaction was completed, the flask was left to stand to separate the resin phase from the sulfuric acid aqueous phase, and then the resin phase was washed with water three times and unreacted spacer was removed at 20 to 30 mmHg and 120 to 130° C. for 20 minutes. xylene to obtain 240 g of a phenol-modified xylene-formaldehyde resin with a viscosity of 1050 centipoise (25° C.).

preparation Embodiment 2

[0089] Preparation Example 2: Preparation of Xylene-Formaldehyde Resin 2

[0090] An o-cresol-modified xylene-formaldehyde resin was prepared in the same manner as in Preparation Example 1, except that 55 g of phenol was replaced with 55 g of o-cresol.

preparation Embodiment 3

[0091] Preparation Example 3: Preparation of Xylene-Formaldehyde Resin 3

[0092] A nonylphenol-modified xylene-formaldehyde resin was prepared in the same manner as in Preparation Example 1 except that 55 g of phenol was replaced with 55 g of nonylphenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com