Hydraulic vibrating pile driver

A vibratory pressure and hydraulic technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of high requirements for motor vibration resistance, large damage to prefabricated piles, environmental pollution, etc., to save energy and steel, harmful The effect of low vibration and no adverse damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

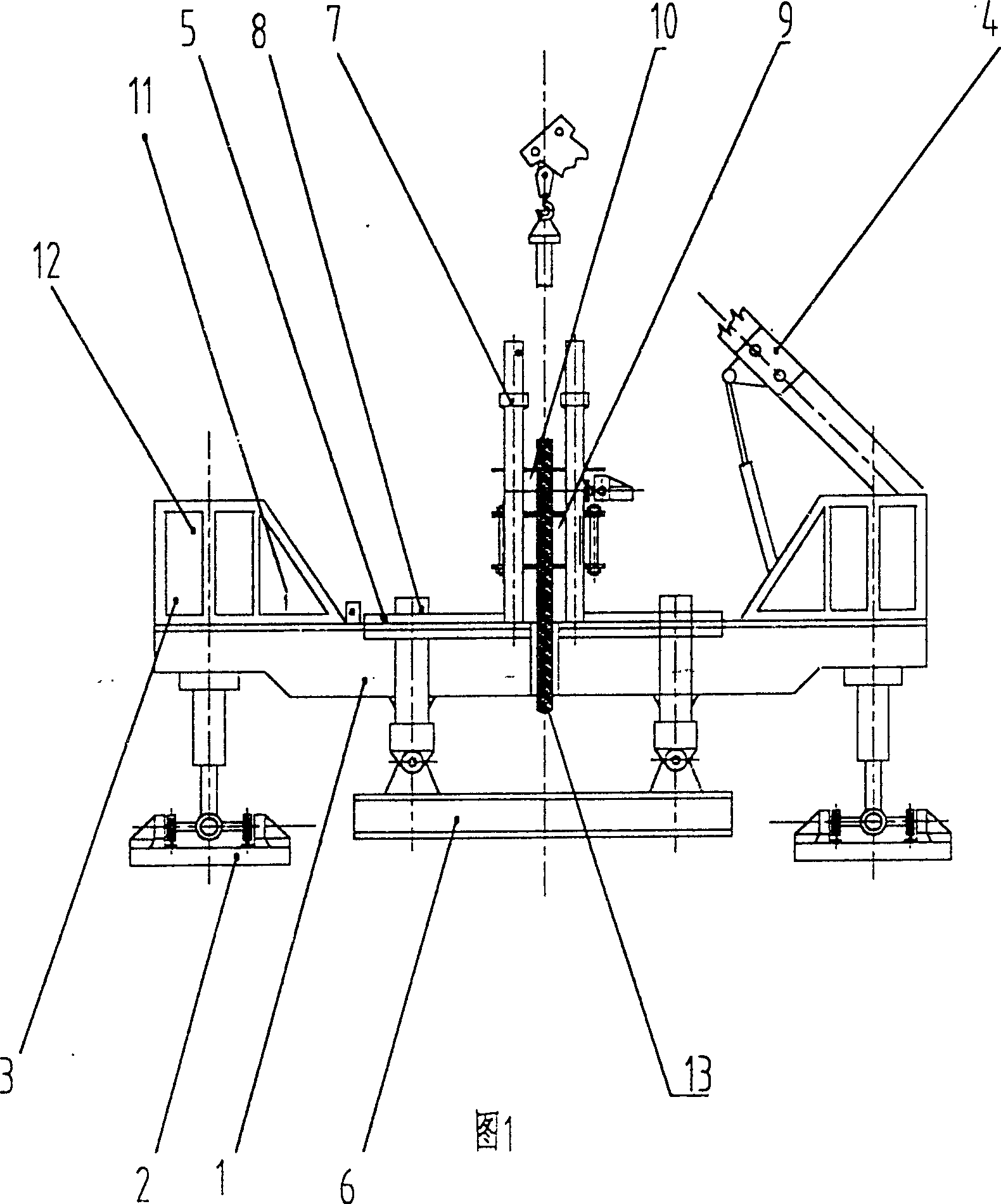

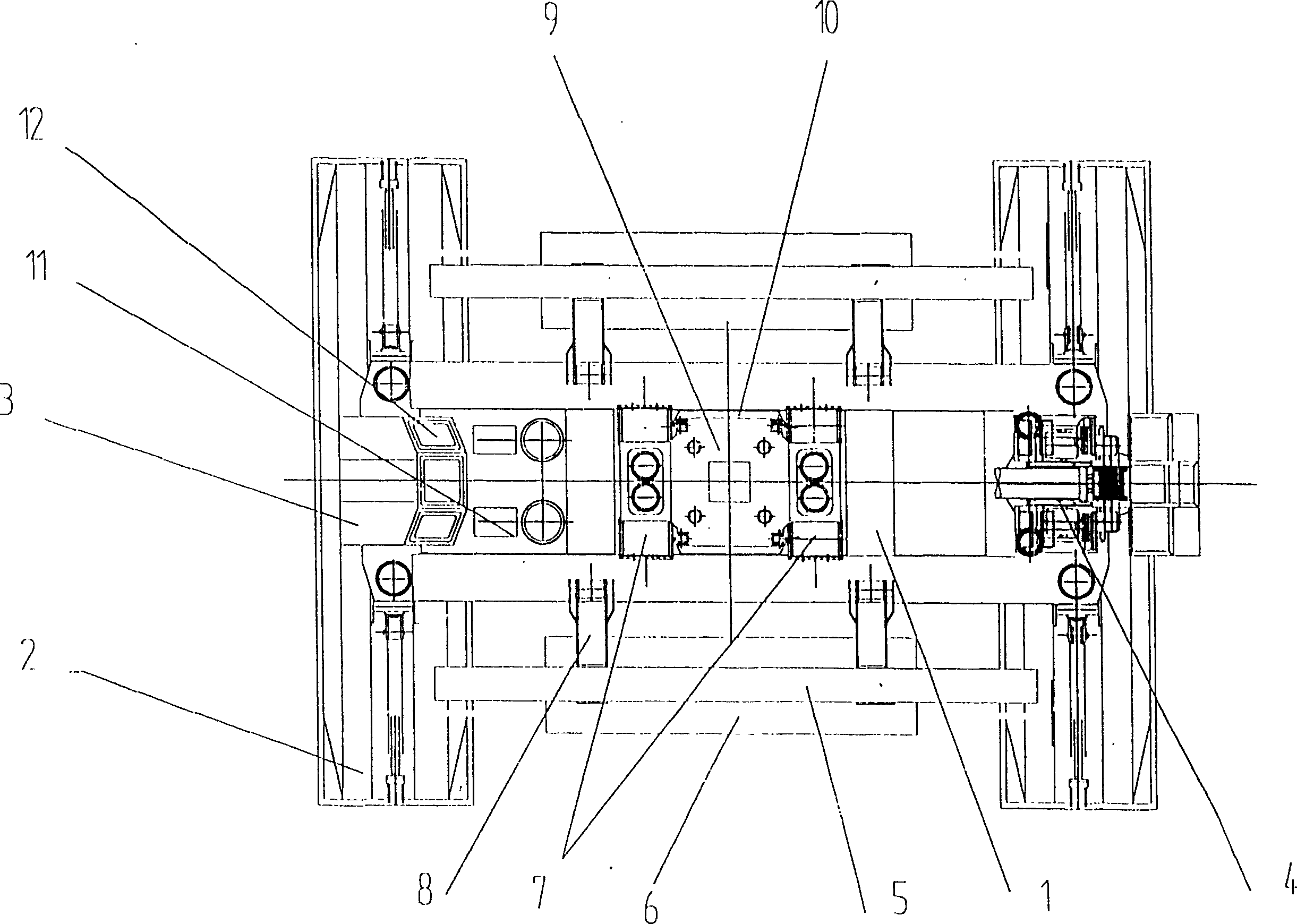

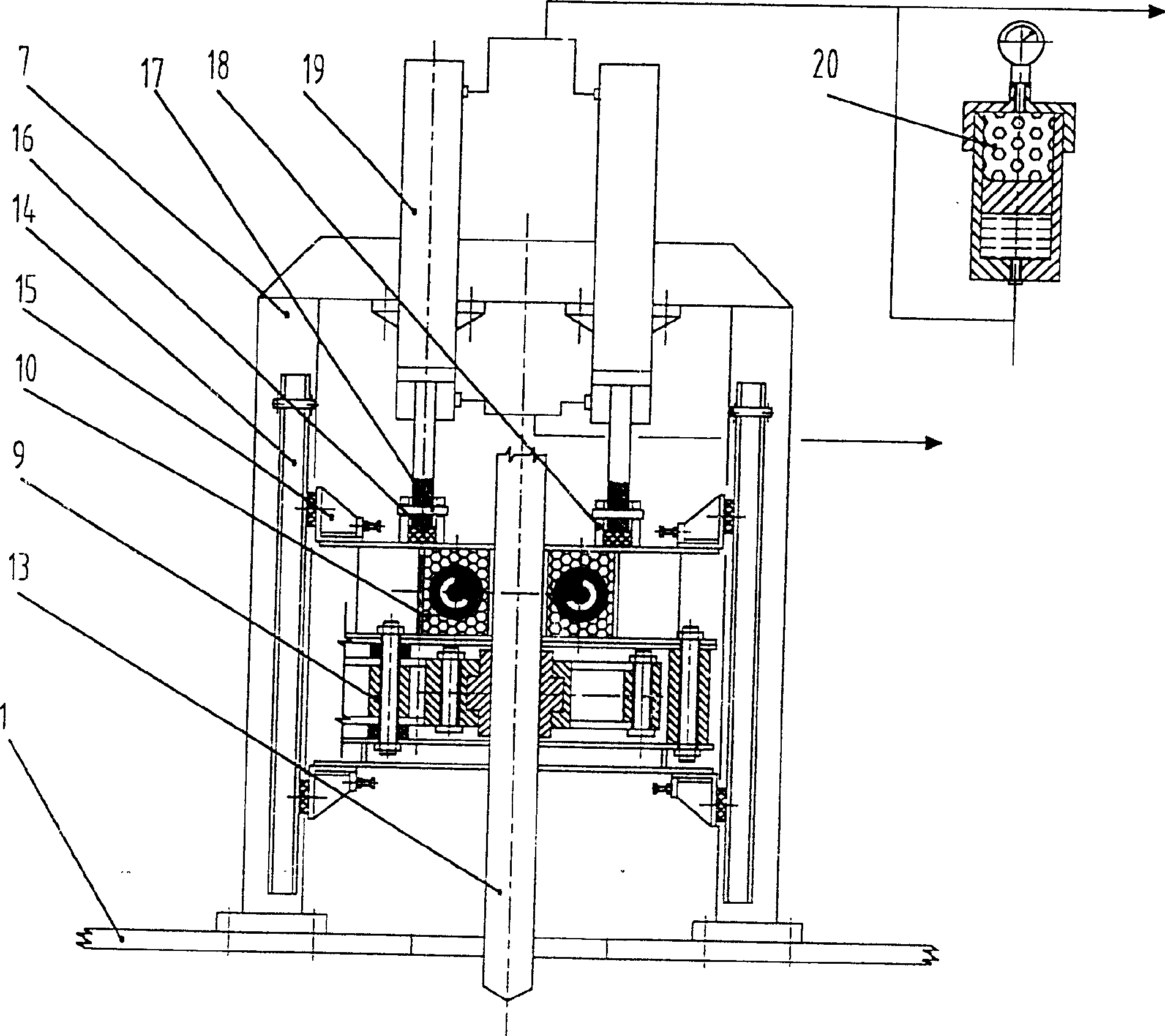

[0016] The hydraulic vibratory pile driver shown in the figure has a rectangular fuselage platform 1, and the fuselage platform 1 is the supporting body of all executive parts. Four jacking cylinders are installed vertically at the four corners of the fuselage platform 1, and the piston rod hinge of the jacking cylinder is connected with the longboat running mechanism 2 through the fork shaft trolley; the two sides of the fuselage platform 1 are hinged with four Support leg 8, the lower end of this support leg 8 links to each other with parts such as bearing pin and short boat running mechanism 6, can realize the horizontal and vertical walking and turning of whole pile driver by long boat running mechanism 2 and short boat running mechanism 6. The counterweight beam 5 and its counterweight are mounted on the legs 8 .

[0017] The right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com