Method for preparing n-type An1-XMgXO crystal film

A zn1-xmgxo, n-type technology is applied in the field of n-type doped Zn1-xMgxO crystal films and their preparation, which can solve the problems affecting the application of crystal films and achieve the effect of high doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

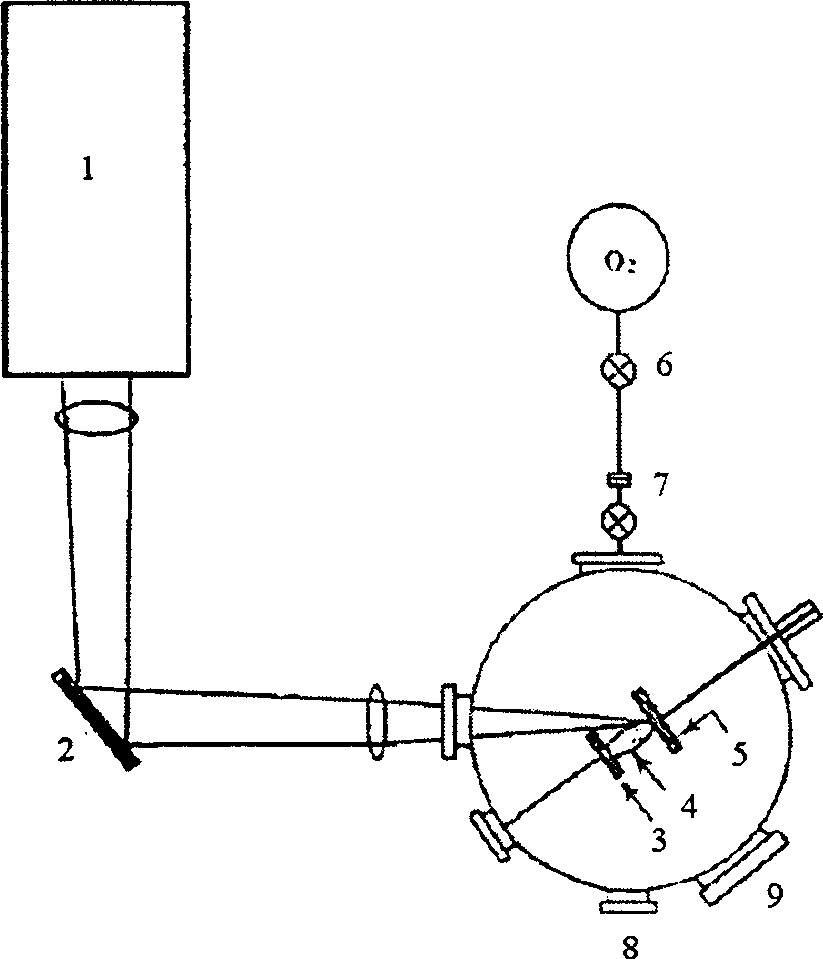

Image

Examples

Embodiment

[0017] 1) Take ZnO, MgO and Al with a purity of 99.99% 2 o 3 powder, wherein the molar content of MgO is 20%, that is, the molar ratio of MgO:ZnO is 1:4, Al 2 o 3 The molar content is 0.1%. Then ZnO, MgO and Al 2 o 3 The powder is mixed and poured into an agate ball cup, and placed on a ball mill for ball milling. On the one hand, ZnO, MgO and Al can be 2 o 3 The powder is mixed evenly to ensure the uniformity of the prepared target. On the other hand, ZnO, MgO and Al 2 o 3 Powder refinement for subsequent ZnO, MgO and Al 2 o 3 Forming and sintering of mixed powders. After the ball milling, add the binder polyvinyl acetate, and press the powder into a disc with a thickness of 3mm and a diameter of 4cm; then sinter the pressed powder disc at 1000°C for 1 hour to form an organic bond. The agent is volatilized, and the Al-doped 2 o 3 Zn 0.8 Mg 0.2 O ceramic target.

[0018] 2) take the silicon chip as the substrate as an example, first clean the silicon chip wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com