A kind of preparation method of n-type SNSE-based thermoelectric nanomaterial

A nanomaterial and thermoelectric technology, which is applied in the manufacture/processing of thermoelectric devices, and lead-out wire materials of thermoelectric devices, can solve problems such as the instability of SnSe materials, reduce lattice thermal conductivity, and achieve excellent overall electrical performance. The effect of optimizing the power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

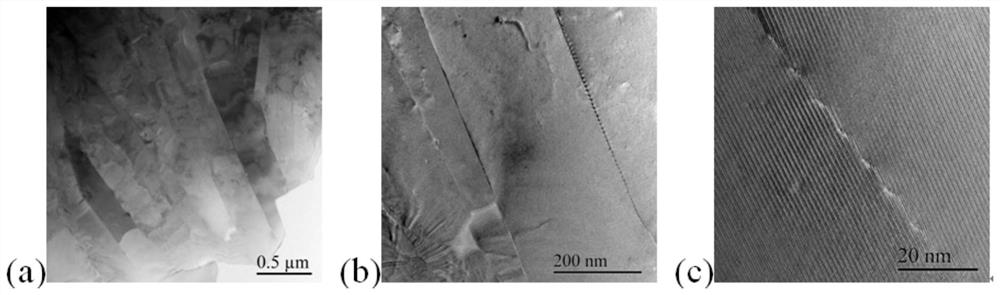

Image

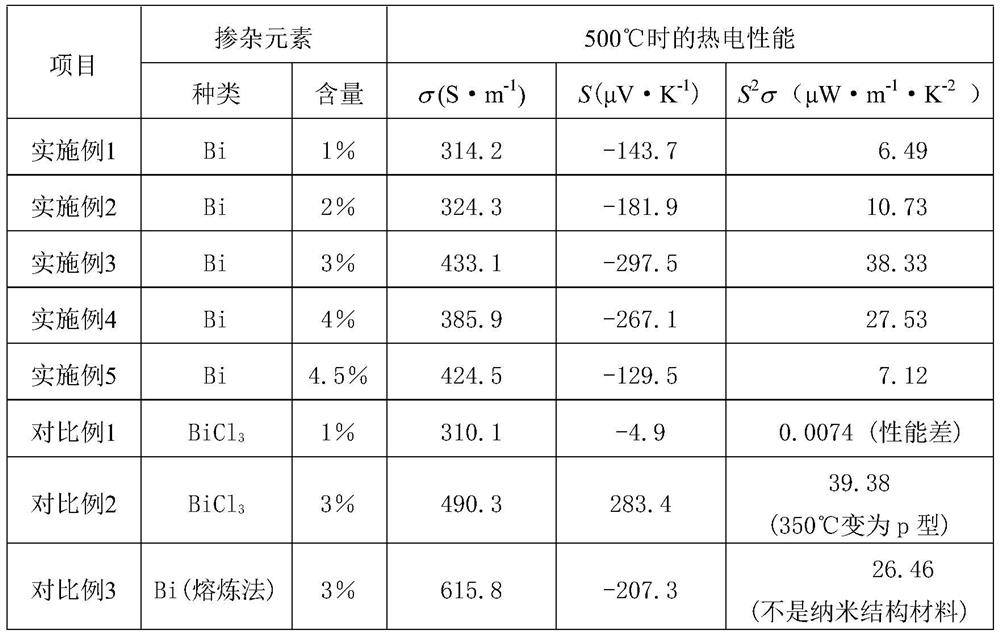

Examples

Embodiment 1

[0026] Using SnCl 2 (mass percentage purity is 98%), Se powder (purity is 99.999%), bismuth 2-ethylhexanoate, NaOH (mass percentage content > 96%), NaBH 4 (mass percentage content is 98%), anhydrous ethylenediamine (mass percentage content > 99%), deionized water are used as reaction raw materials, and solid medicine is stored in the glove box, and all raw materials are purchased from the market without secondary treatment Use directly.

[0027] The complete preparation process is as follows: NaOH (3g) and NaBH 4 (1g) was dissolved in a mixture of 120ml deionized water and 40ml anhydrous ethylenediamine, and then transferred to a mixture containing Se powder (10mmol), SnCl 2 (9.9mmol) and bismuth 2-ethylhexanoate (0.1mmol) in a flask, the flask was connected to the Schlank reaction line, after the oxygen removal operation, the temperature was raised to 150°C with an oil bath, and the reaction was carried out for 2h. After the reaction was completed, it was cooled in an ice-...

Embodiment 2

[0029] On the basis of Example 1, adjust SnCl 2 The dosage of bismuth 2-ethylhexanoate is 9.8mmol, and the dosage of bismuth 2-ethylhexanoate is 0.2mmol to obtain an n-type SnSe-based thermoelectric nanomaterial with a Bi-doped molar percentage of 2%.

Embodiment 3

[0031] On the basis of Example 1, adjust SnCl 2 The dosage of bismuth 2-ethylhexanoate is 9.7mmol, and the dosage of bismuth 2-ethylhexanoate is 0.3mmol to obtain an n-type SnSe-based thermoelectric nanomaterial with a Bi-doped molar percentage of 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com