Static relay and communication device using static relay

A relay and electrostatic technology, applied in the field of electrostatic relays, can solve the problems of increased contact resistance between contacts, decreased contact force between contacts, and reduced electrostatic attraction, etc., to achieve reduced insertion loss, easy processing, and good high-frequency characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

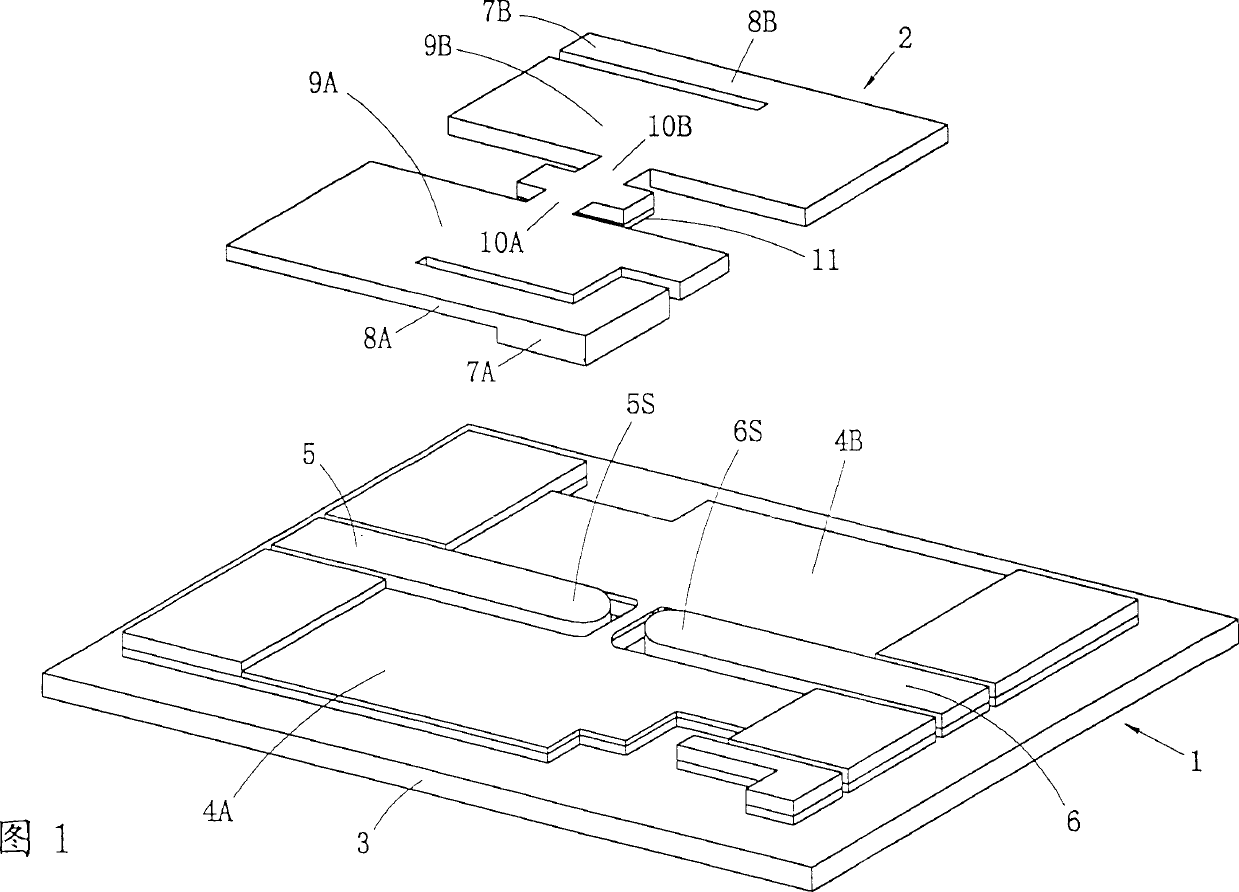

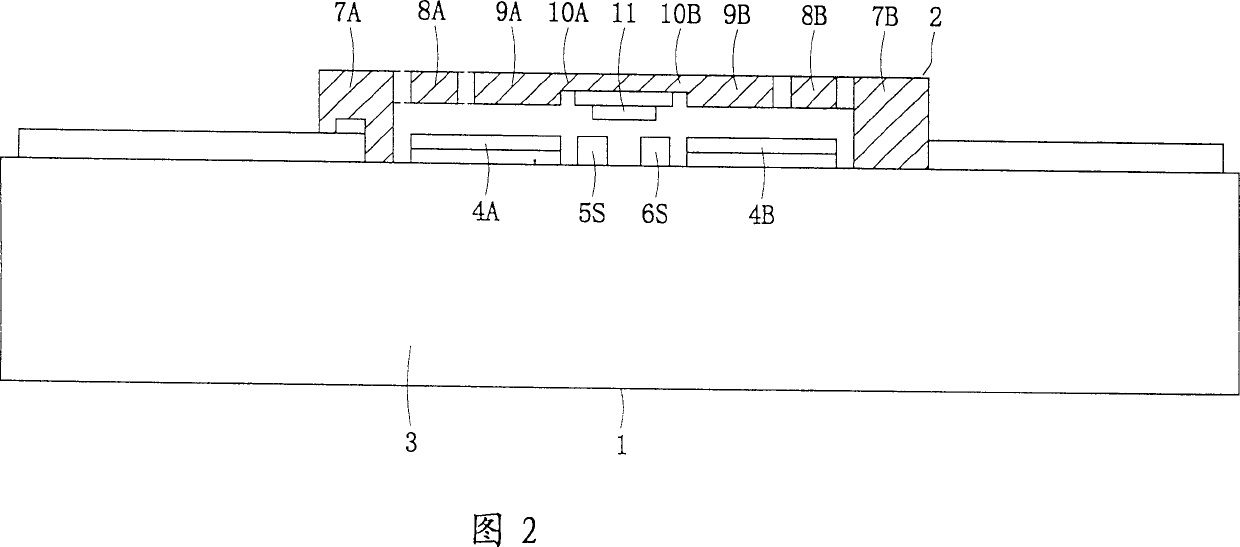

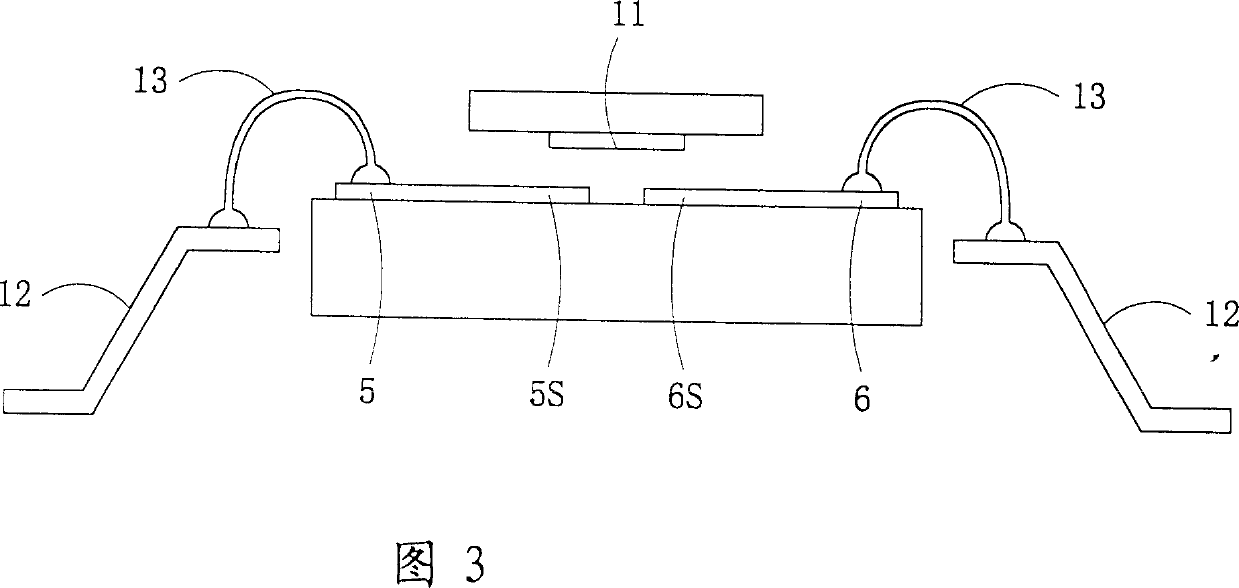

[0065] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0066] Fig. 4 is an exploded oblique view of the structure of an electrostatic micro-relay according to an embodiment of the present invention. Fig. 5 is a step-by-step sectional view taken along line X-X in Fig. 4 . This electrostatic micro-relay is mainly made of fixed substrate 20, movable substrate 40 and cap 50, and movable substrate 40 is installed on the top of fixed substrate 20 for integration, and the top of fixed substrate 20 and movable The substrate 40 is sealed between the fixed substrate 20 and the cap 50 . FIG. 6 is a perspective view seen from the back side of this fixing substrate 20, and FIG. 7 is a perspective view seen from the back side of the cap 50. As shown in FIG.

[0067] As shown in FIG. 4, the above-mentioned fixed substrate 20 is a substrate in which fixed electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com