Thin film piezoelectric resonator, thin film piezoelectric device, and manufacturing method thereof

a piezoelectric device and thin film technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostriction/magnetostriction machines, electrical apparatus, etc., can solve the problems of large insertion loss of thin film piezoelectric devices prepared by combining a plurality of fbar resonators, long complicated steps are required, and the planar shape of the diaphragm is preferably optimized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

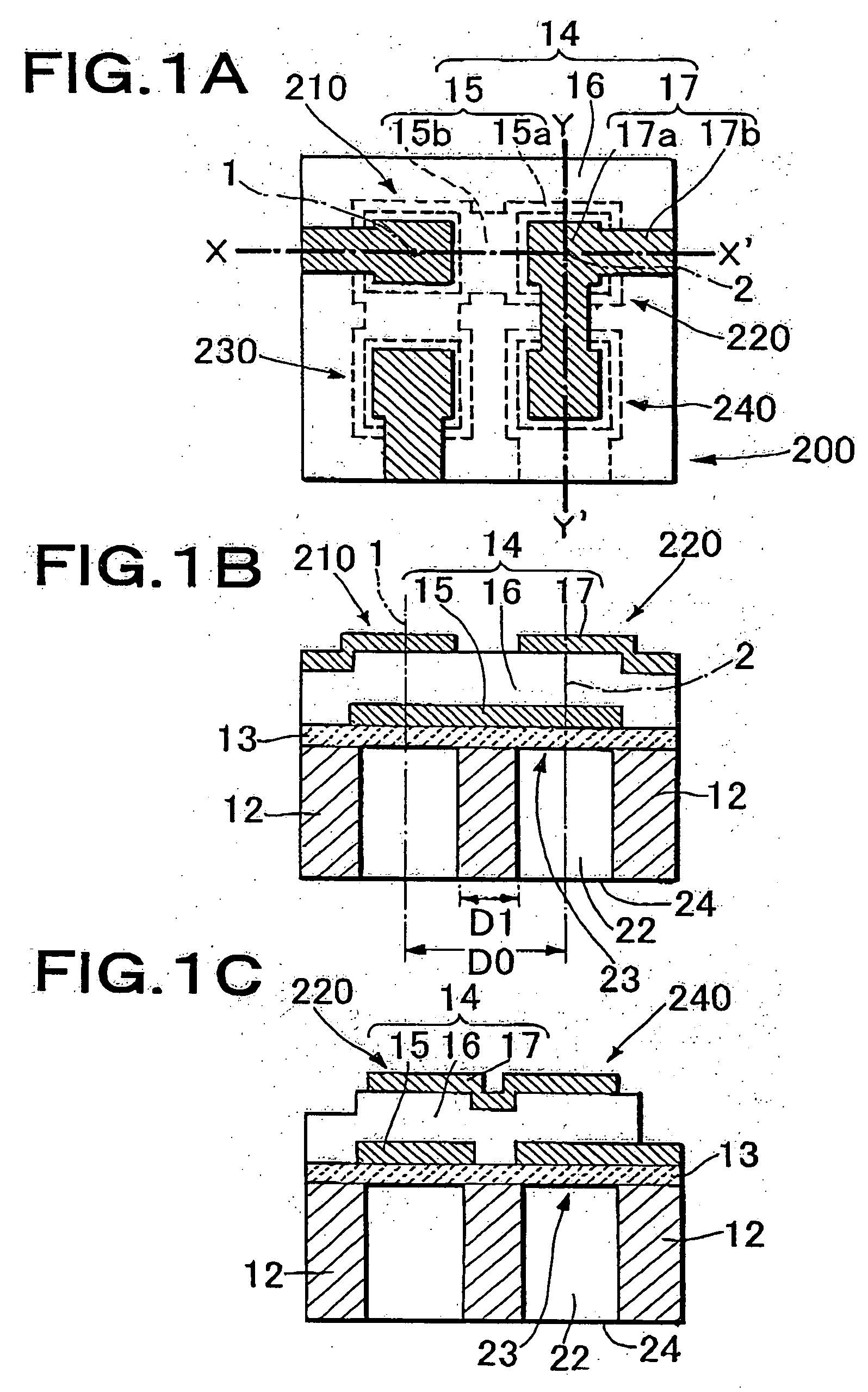

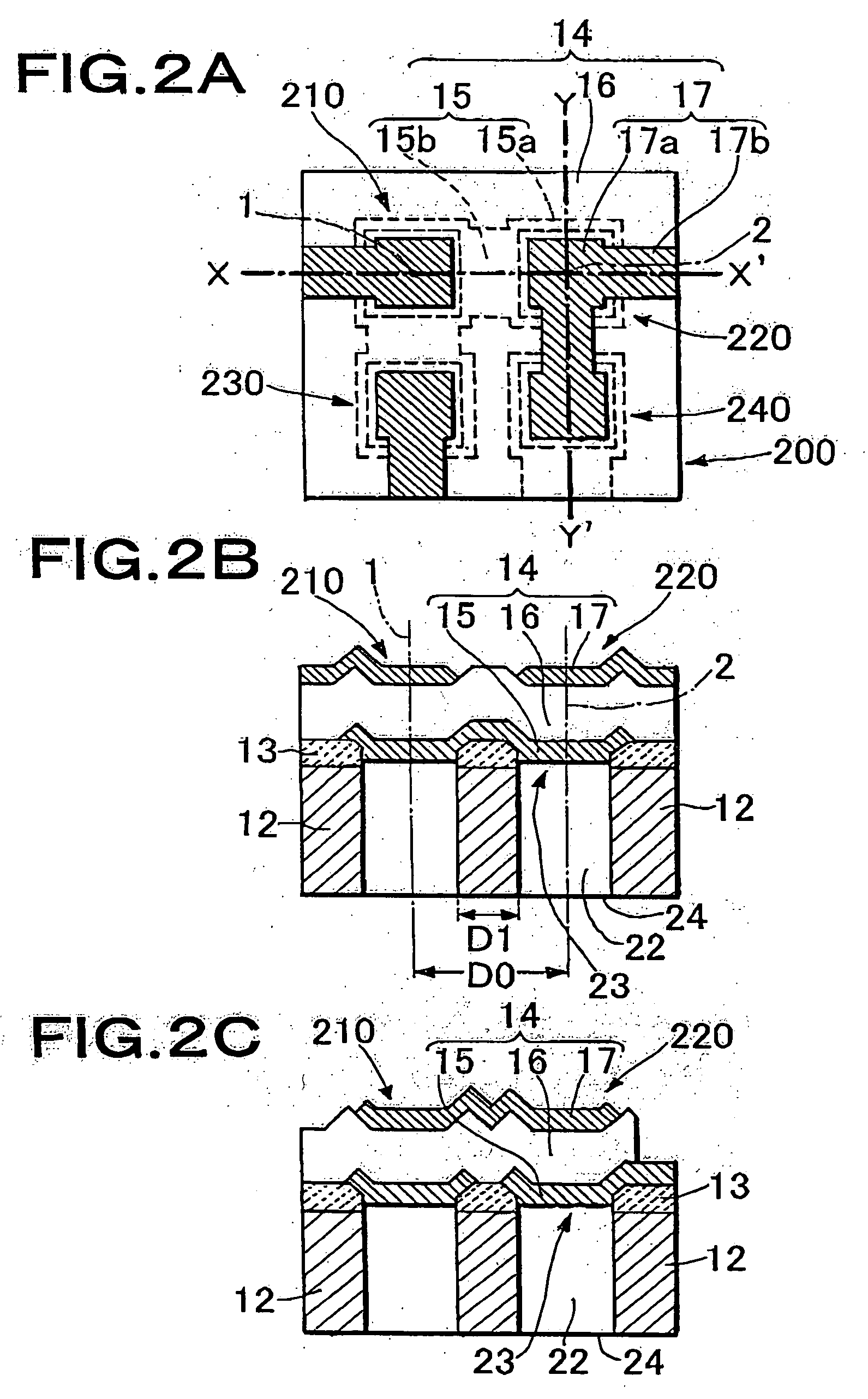

[0111] In the present example, a thin film piezoelectric filter shown in FIGS. 2A to 2C was prepared as follows.

[0112] That is, the upper surface of a (100) Si substrate 12 having a thickness of 250 μm was patterned and etched into a desired shape by photolithography, so that a depression was disposed in periphery thereof in such a manner that a flat base having a nearly rectangular shape with a height of 3.0 μm and a planar dimension of about 140×160 μm was left. It is to be noted that the base was formed in a position corresponding to a diaphragm of an resonator to be formed. After forming SiO2 layers each having a thickness of 1.0 μm on opposite upper / lower surfaces of a substrate by a thermal oxidation method, an SiO2 layer having a thickness of 3.5 μm was deposited on the upper surface of the substrate at 450° C. by a thermal CVD method using tetraethoxy silane (Si(O(C2H5)4) in a raw material, and annealed at 1000° C. Next, the SiO2 layer on the upper surface of the substrate ...

example 2

[0121] In the present example, a thin film piezoelectric filter having the structure (the diaphragm 23 is trapezoidal) shown in FIG. 2 was prepared as follows.

[0122] That is, an procedure similar to that of Example 1 was repeated to prepare the thin film piezoelectric filter comprising the ladder type circuit except that a Ti metal layer (adhesive layer), a Pt metal layer (intermediate layer), and a Mo metal layer (main electrode layer) were deposited as a lower electrode in this order to form a Mo / Pt / Ti lower electrode 15 having a material and thickness described in Table 1, a Ti metal layer (adhesive layer) and a Mo metal layer (main electrode layer) were deposited as an upper electrode in this order to form a Mo / Ti upper electrode 17 having a material and thickness described in Table 1, and the planar shape of a via hole fabricated by deep RIE was formed to be trapezoidal to thereby form a diaphragm 23 into a trapezoidal shape. The above described D1 / D0 of the present example wa...

example 3

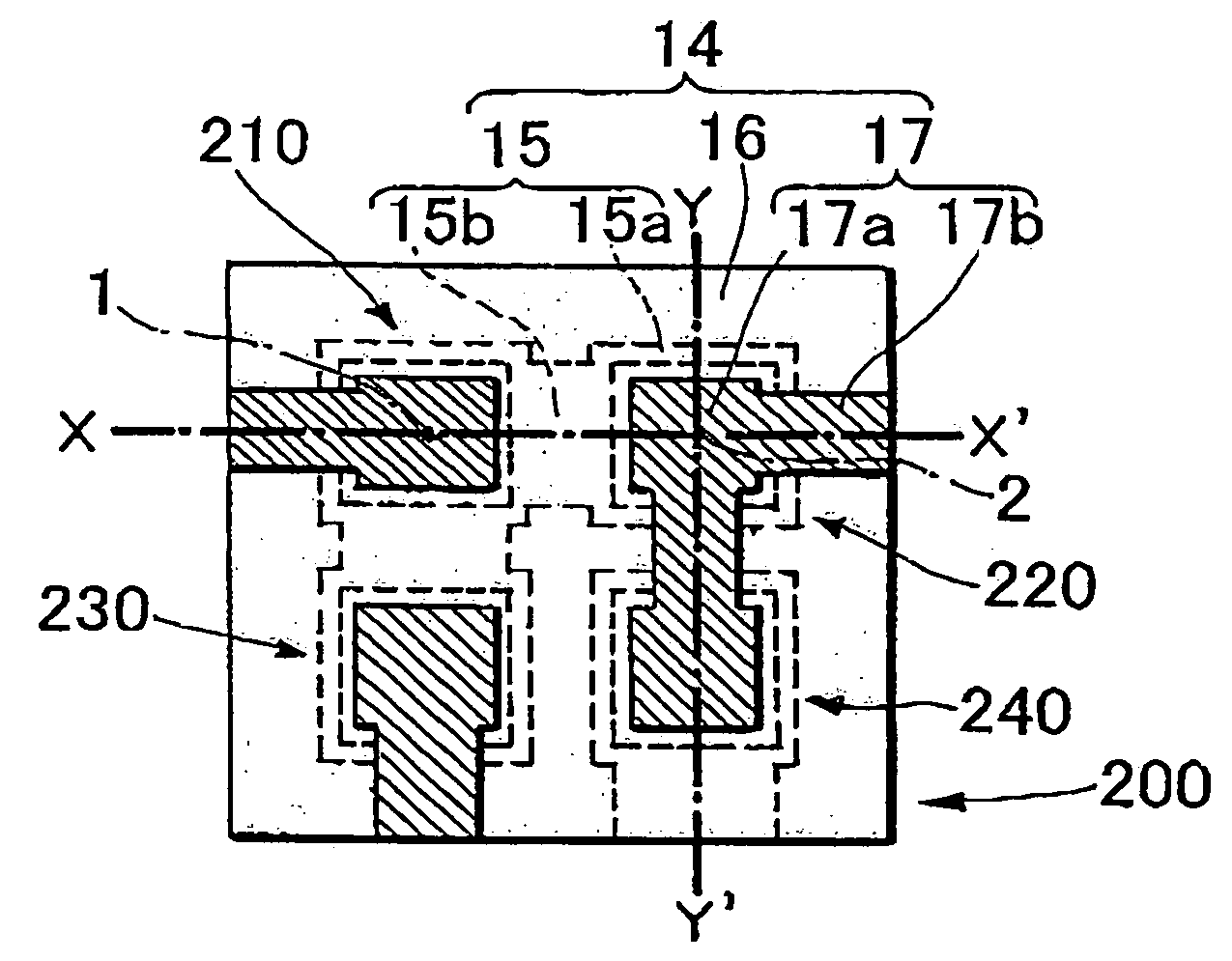

[0126] In the present example, a thin film piezoelectric filter having the structure (the diaphragm 23 was trapezoidal) shown in FIG. 1 was prepared as follows.

[0127] That is, after forming SiO2 layers each having a thickness of 1.2 μm on opposite upper / lower surfaces of a (100) Si substrate 12 having a thickness of 250 μm by a thermal oxidation method, the only SiO2 layer on the upper surface was etched to adjust the thickness of the SiO2 layer on the upper surface, and an insulating layer 13 made of SiO2 and having a thickness value described in Table 1 was formed. A Ti metal layer (adhesive layer), an Au metal layer (intermediate layer), and a Mo metal layer (main electrode layer) were deposited on the upper surface of the insulating layer 13 in this order by a DC magnetron sputtering method, and patterned into a desired shape by photolithography to form a Mo / Au / Ti lower electrode 15. A main body portion 15a of the lower electrode 15 was formed into a nearly rectangular shape. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com