Manufacture of erbium dosed phosphate two step ion exchange optical waveguide

A technology of ion exchange and erbium phosphate, which is applied in the field of optical communication, can solve the problems of large transmission loss of optical waveguide, stagnation, and complex experimental equipment, etc., and achieves short process cycle, good stability, and symmetrical refractive index distribution Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

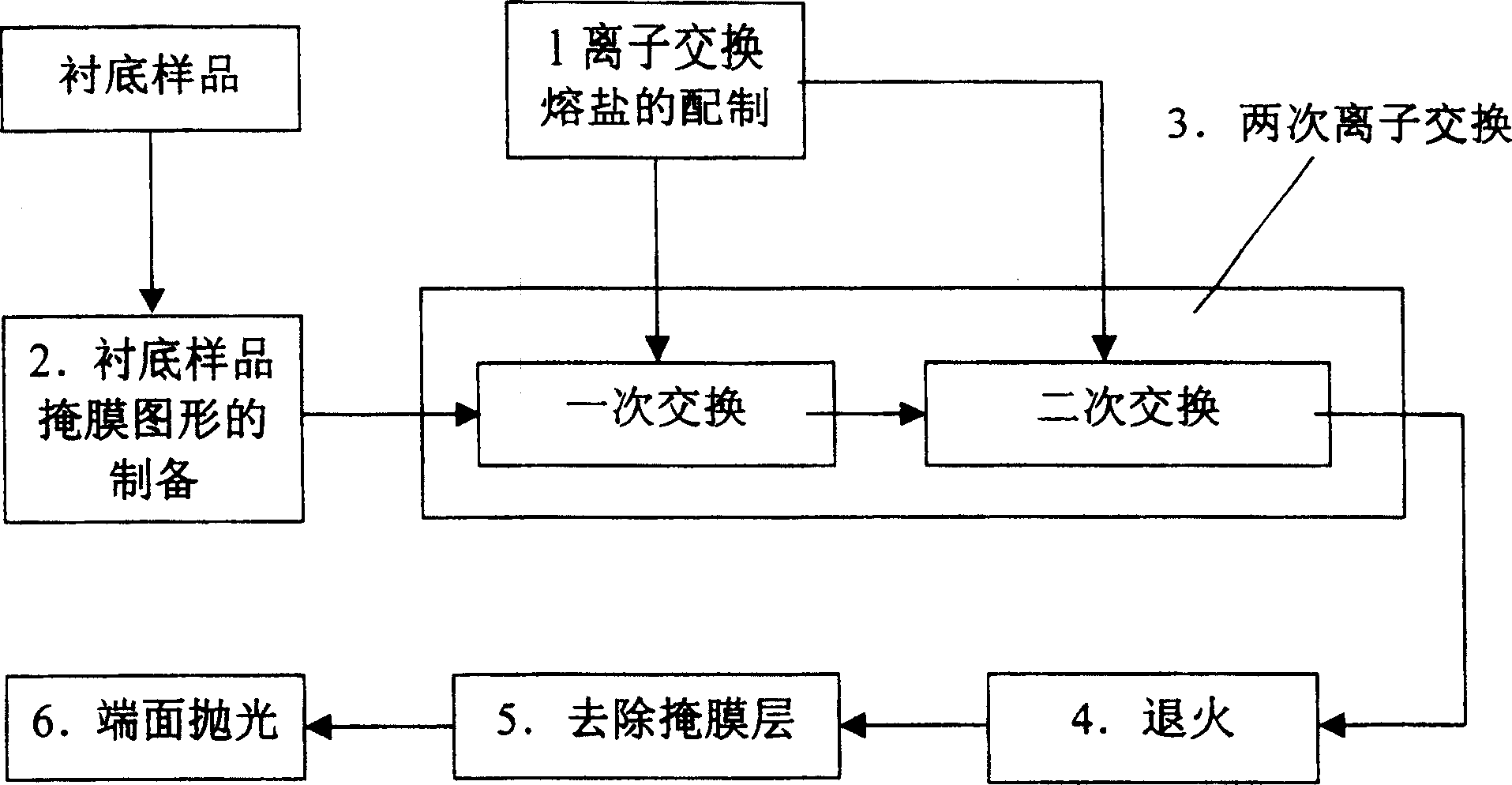

Method used

Image

Examples

Embodiment 1

[0021] No. 1 salt bath: 10% silver nitrate, 90% potassium nitrate; No. 2 salt bath: 10% potassium nitrate, 90% sodium nitrate, with a mask thickness of 1200 angstroms. Put the salt and the sample in a constant temperature furnace to preheat to the primary exchange temperature of 330 degrees Celsius, then immerse the sample in the No. Take out the salt bath reaction for 30 minutes, then adjust the furnace temperature to 340 degrees Celsius, keep it for 20 minutes, turn off the power, let it cool naturally, and then take out the sample. After the aluminum film on the surface was dissolved with hot phosphoric acid, the sample was washed and finally polished. According to the obtained results, the waveguide with a width of 6.5 microns has a transmission loss of 1.2dB / cm and a PDL<0.3dB; the waveguide with a width of 6 microns has a transmission loss of 0.70dB / cm and a PDL<0.3dB. The rest of the waveguide width cannot be measured due to damage during the process.

Embodiment 2

[0023] No. 1 salt bath: 8% silver nitrate, 92% potassium nitrate; No. 2 salt bath: 100% sodium nitrate. The primary exchange temperature is 335 degrees Celsius, and the reaction time is 100 minutes; the secondary exchange temperature is 320 degrees Celsius, the reaction time is 25 minutes, and the annealing temperature is 345 degrees Celsius. Others are the same as in Example 1. The obtained results: 7.0 micron width waveguide: transmission loss 0.57dB / cm, PDL<0.2dB; 6 micron width waveguide, transmission loss 0.72dB / cm, PDL<0.2dB.

Embodiment 3

[0025] No. 2 salt bath: 5% potassium nitrate, 95% sodium nitrate, mask thickness 1500 angstroms, primary exchange temperature 340 degrees centigrade, reaction time is 90 minutes; secondary exchange temperature 325 degrees centigrade, reaction time 20 minutes, all the other are the same as embodiment 1 , The results obtained: 7.0 micron width waveguide: transmission loss 1.1dB / cm, PDL<0.2dB; 6 micron width waveguide, transmission loss 0.83dB / cm, PDL<0.2dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com