Production method of transplanting material

A manufacturing method and technology of implant materials, which are applied in the fields of biochemical equipment and methods, medical science, microorganisms, etc., can solve problems such as failure to achieve biological healing, aqueous humor leakage implants, corneal dissolution, etc. Effects of treating refractive errors and increasing corneal thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

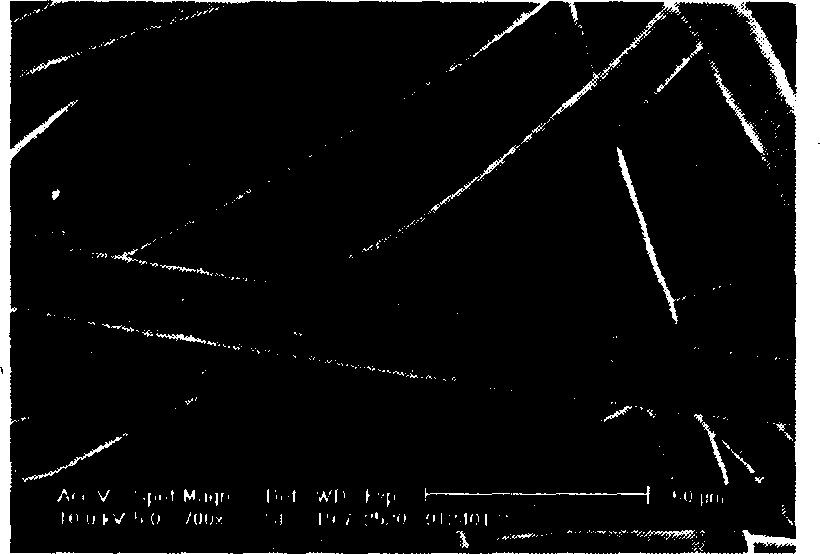

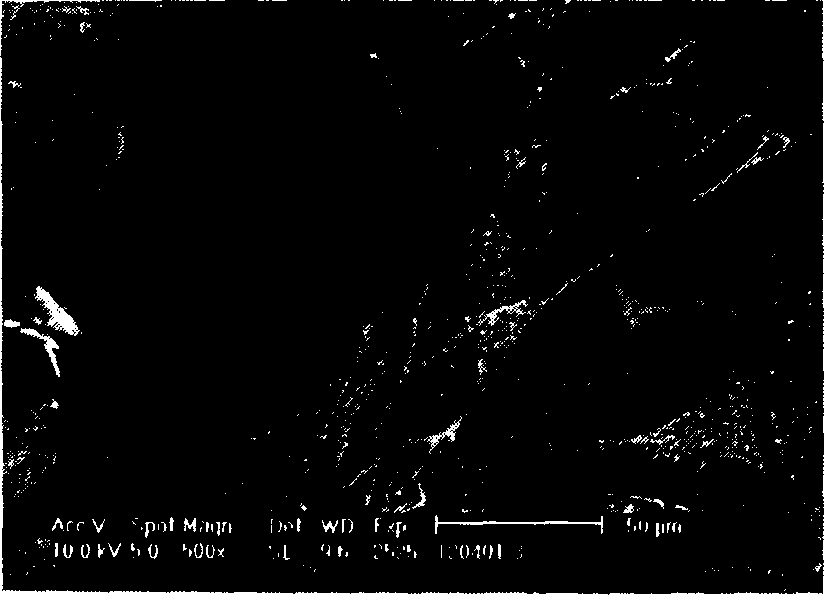

[0031] Now, with reference to the accompanying drawings, the method for manufacturing the graft material used for corneal stromal ring implantation of the present invention will be further described in detail.

[0032]The manufacturing method of the graft material of the present invention mainly includes the following steps: step 1, preparing biological scaffold; step 2, separating and culturing biological corneal stromal cells; and step 3, preparing corneal stromal cell-biological scaffold complex, and prefabricating corneal stromal tissue. The manufacturing method of the graft material of the present invention further includes step 4, implanting the forming cell-biological material compound obtained in step 3 into the corneal stroma lamina of the living body to obtain new tissue-engineered corneal stroma tissue.

[0033] The method for manufacturing graft material of the present invention is described below through specific experiments:

[0034] 20 litters of New Zealand whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com