Laminated glass material

A glass material and lamination technology, which is applied in the field of laminated glass materials, can solve the problems of not improving the up-conversion luminous intensity of blue-green light, the decrease of up-conversion luminous intensity, and the decrease of blue-green light intensity, so as to improve the up-conversion luminescence Efficiency, significant application prospects, and the effect of avoiding fluorescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

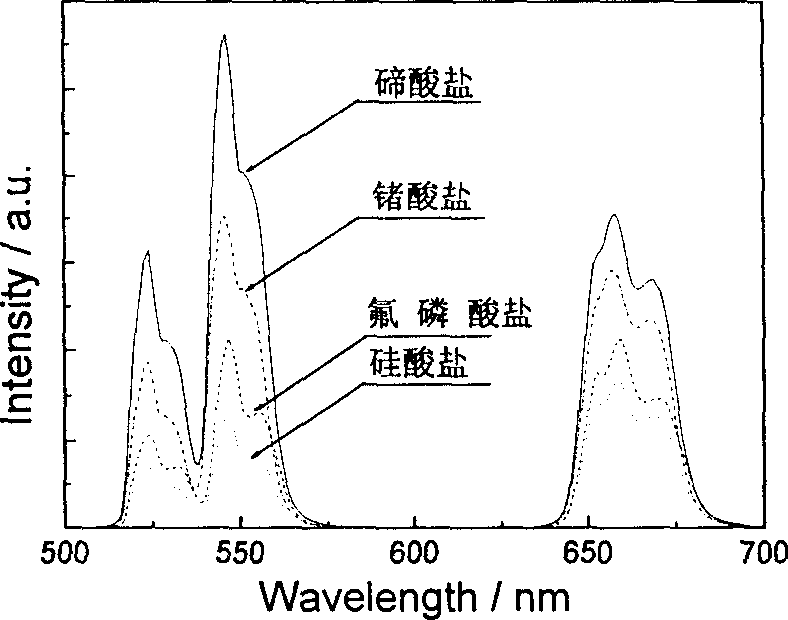

[0022] Matrix glass is 5K 2 O-10ZnO-10BaO-20PbO-20GeO 2 -35TeO 2 (molar parts, the same below)

[0023] The laminated glass material is composed of two glass materials superimposed,

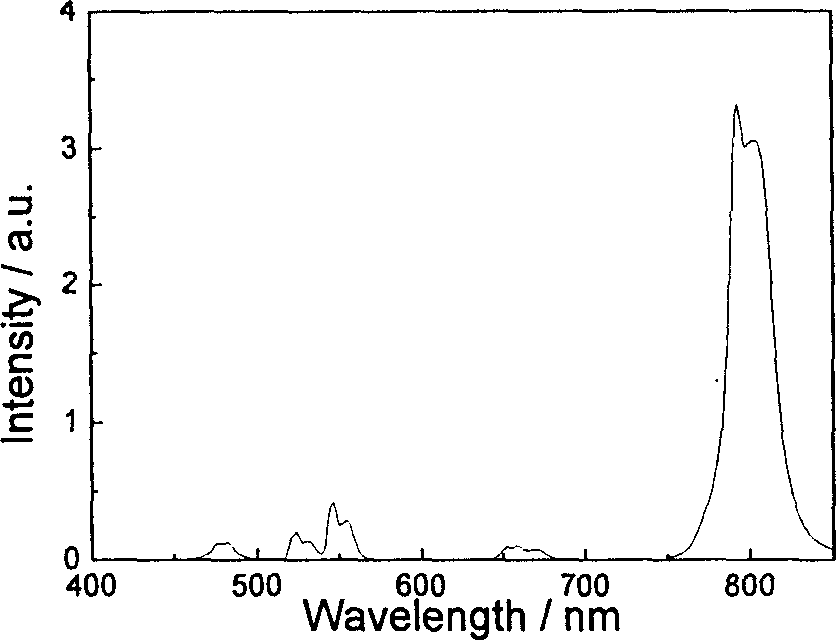

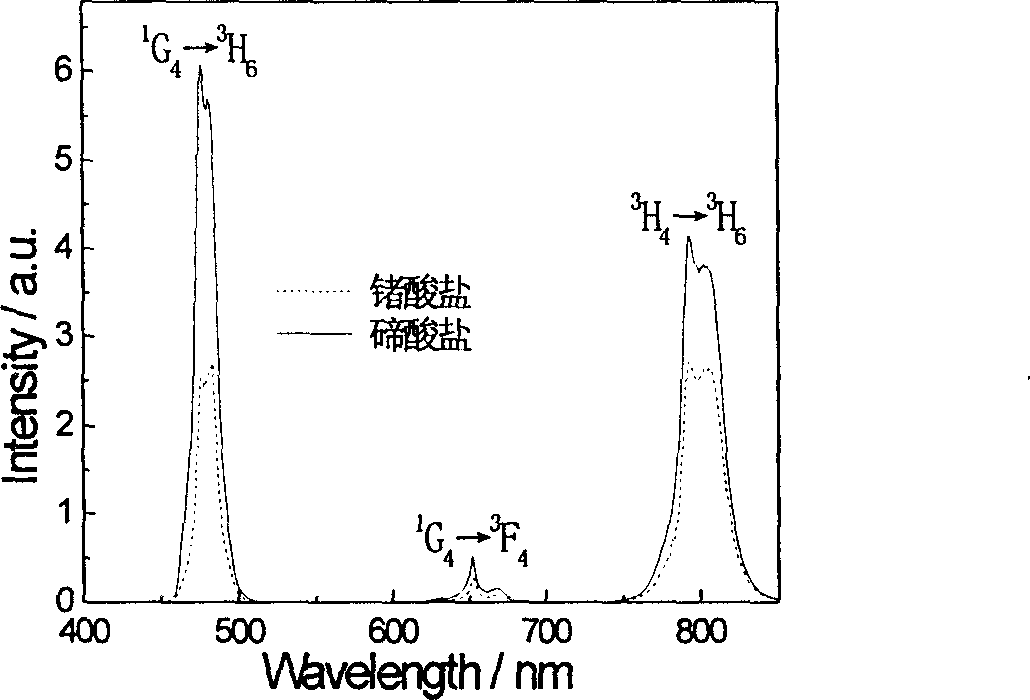

[0024] A piece doped with Yb 3+ / Er 3+ , Yb 3+ Addition amount is 1.4mol, Er 3+ The dosage is 0.2mol;

[0025] The other piece is doped with Yb 3+ / Tm 3+ , Yb 3+ Addition amount is 1.4mol, Tm 3+ The added amount is 0.1 mol.

[0026] The molar addition amount mentioned above is based on 100 mol of matrix glass, and the thickness of each piece of glass is 0.05 mm.

[0027] The preparation process of the laminated glass material is a known technology as described in the technical solution.

Embodiment 2

[0029] Matrix glass is 5K 2 O-10ZnO-10BaO-20PbO-20GeO 2 -35TeO 2 Glass (mole parts)

[0030] The laminated glass material is composed of three glass materials superimposed,

[0031] The first and third glass materials are doped with Yb 3+ / Er 3+ , Yb 3+ Addition amount is 1.4mol, Er 3+ The dosage is 0.2mol;

[0032] The second glass material is doped with Yb 3+ / Tm 3+ , Yb 3+ Addition amount is 1.4mol, Tm 3+ The added amount is 0.1 mol.

[0033]The molar additions mentioned above are based on 100 mole parts of the matrix glass, and the thickness of each piece of glass is 0.3 mm.

[0034] The preparation process of the laminated glass material is a known technology as described in the technical solution.

Embodiment 3

[0036] The matrix glass is 35TeO 2 -20GeO 2 -20BiO 3 / 2 -10BaO-10ZnO-5K 2 O glass.

[0037] The first and third glass materials are doped with Yb 3+ / Er 3+ , Yb 3+ Addition amount is 1.4mol, Er 3+ The dosage is 0.2mol;

[0038] The second and fourth layers of glass materials are doped with Yb 3+ / Tm 3+ , Yb 3+ Addition amount is 1.4mol, Tm 3+ The added amount is 0.1 mol.

[0039] The above molar additions are based on 100 mole parts of the matrix glass, and the thickness of each piece of glass is 0.50 mm.

[0040] The preparation process of the laminated glass material is a known technology as described in the technical solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com