Method for preparing functionalized carbon-coated magnetic nanoparticles

A magnetic nanoparticle, carbon coating technology, applied in the fields of magnetic materials, nanotechnology, nanotechnology, etc., can solve the problems of poor product size uniformity, complex synthesis method, glued together, etc., to achieve good stability and simple process. , the effect of response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 0.30g of ferrocene and dissolve it in 30mL of acetone, and ultrasonicate for 10min to form a uniform solution;

[0032] (2) Add 0.0015g of polyacrylic acid to the above solution, and fully magnetically stir for 20min at 500rpm to form a precursor;

[0033] (3) The precursor was transferred to a stainless steel autoclave with a sealed polytetrafluoroethylene liner, and reacted at 200 °C for 18 h.

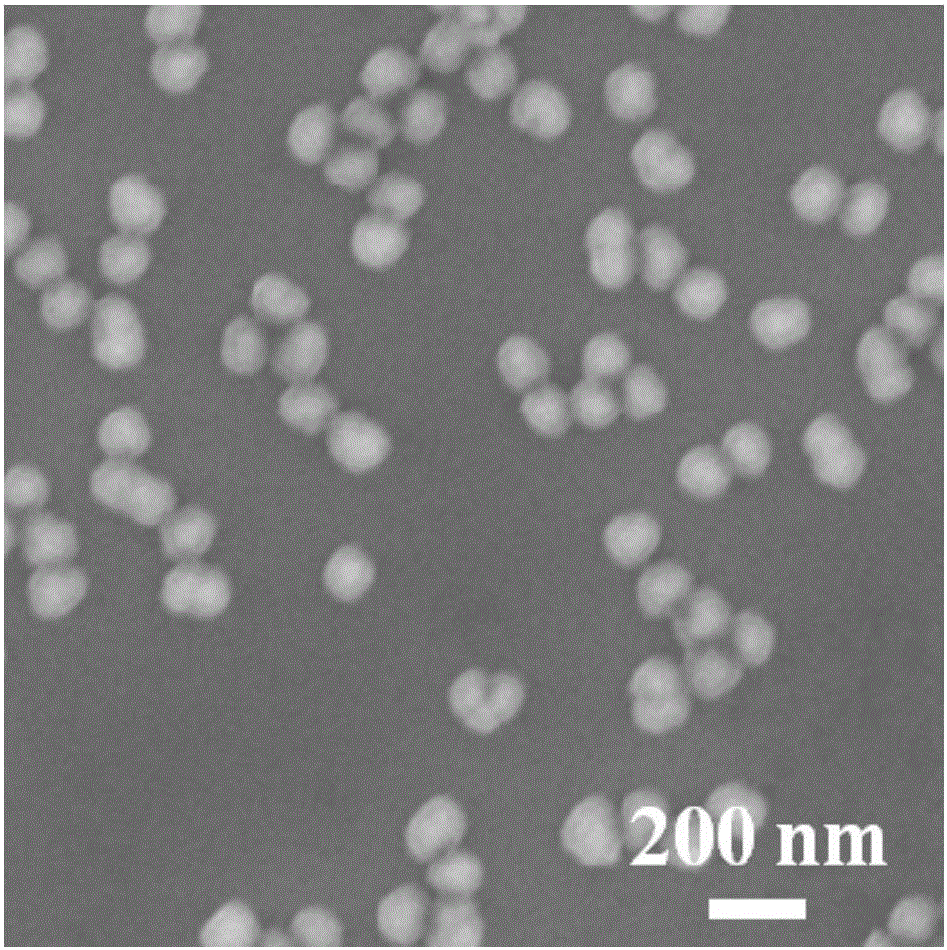

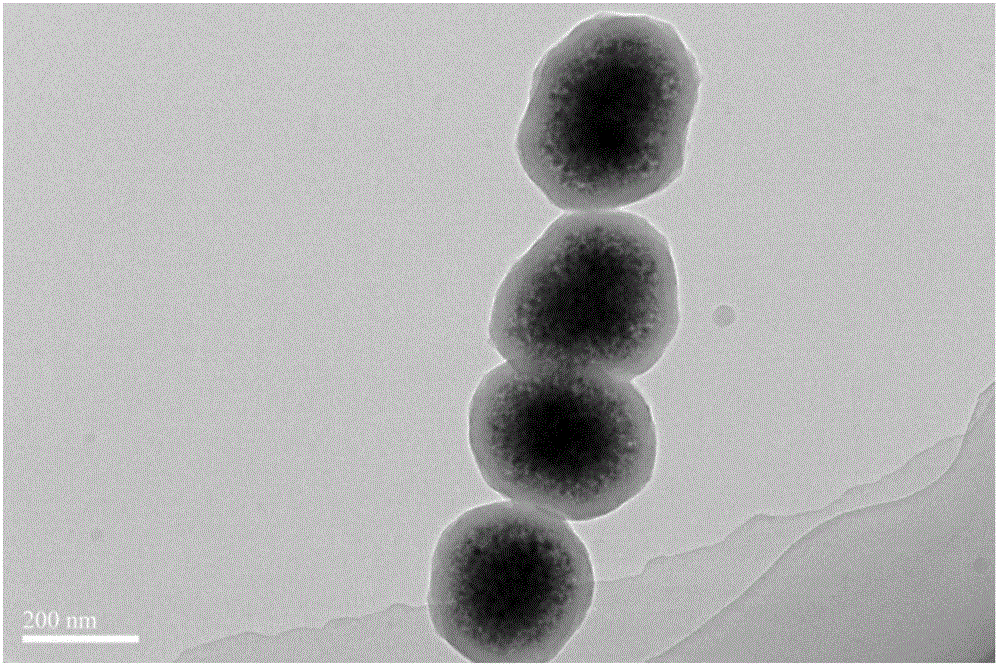

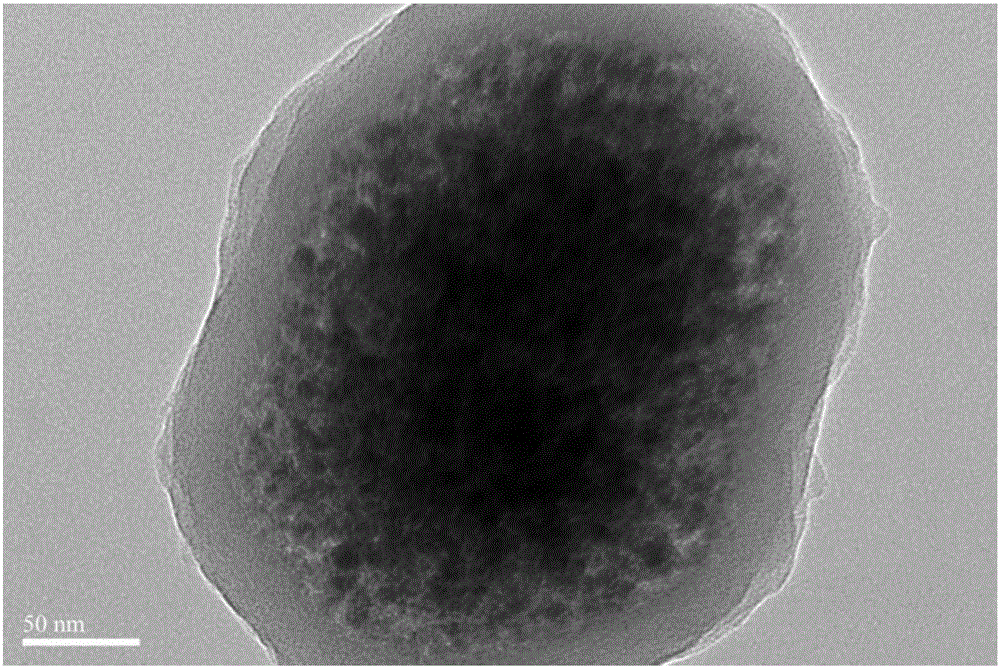

[0034] The magnetic particles prepared above are detected, figure 1 The scanning electron microscope of the magnetic particles prepared in this embodiment shows that the particle size is uniform, the dispersion is good, and there is no agglomeration phenomenon. figure 2 , image 3 and Figure 4 The transmission electron micrograph of the magnetic particles prepared in this example shows that the magnetic particles are uniformly dispersed and have good dispersibility, and each magnetic particle is formed by stacking smaller nanoparticles. The carbon layer coated on...

Embodiment 2

[0036] (1) Weigh 0.20g of ferrocene and dissolve it in 30mL of acetone, and ultrasonicate for 10min to form a uniform solution;

[0037] (2) Add 0.001g of polyacrylic acid to the above solution, and fully magnetically stir at 500rpm for 20min to form a precursor;

[0038] (3) The precursor was transferred to a stainless steel autoclave with a sealed polytetrafluoroethylene liner, and reacted at 200 °C for 18 h.

[0039] After testing, the obtained functionalized carbon-coated magnetic nanoparticles are carbon-coated Fe with uniform size, uniform shape and uniform dispersion. 3 o 4 magnetic nanoparticles.

Embodiment 3

[0041] (1) Weigh 0.35g of ferrocene and dissolve it in 30mL of acetone, and ultrasonicate for 10min to form a uniform solution;

[0042] (2) Add 0.0015g of polyacrylic acid to the above solution, and fully magnetically stir for 20min at 500rpm to form a precursor;

[0043] (3) The precursor was transferred to a stainless steel autoclave with a sealed polytetrafluoroethylene liner, and reacted at 200 °C for 18 h.

[0044] After testing, the obtained functionalized carbon-coated magnetic nanoparticles are carbon-coated Fe with uniform size, uniform shape and uniform dispersion. 3 o 4 magnetic nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com