Preparation technology of azo active dye

A reactive dye and preparation process technology, applied in the field of dye preparation technology, can solve the problems of unattainable, low absolute dye fixation rate, etc., and achieve the effects of high reactivity, good fixation ability, and excellent performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

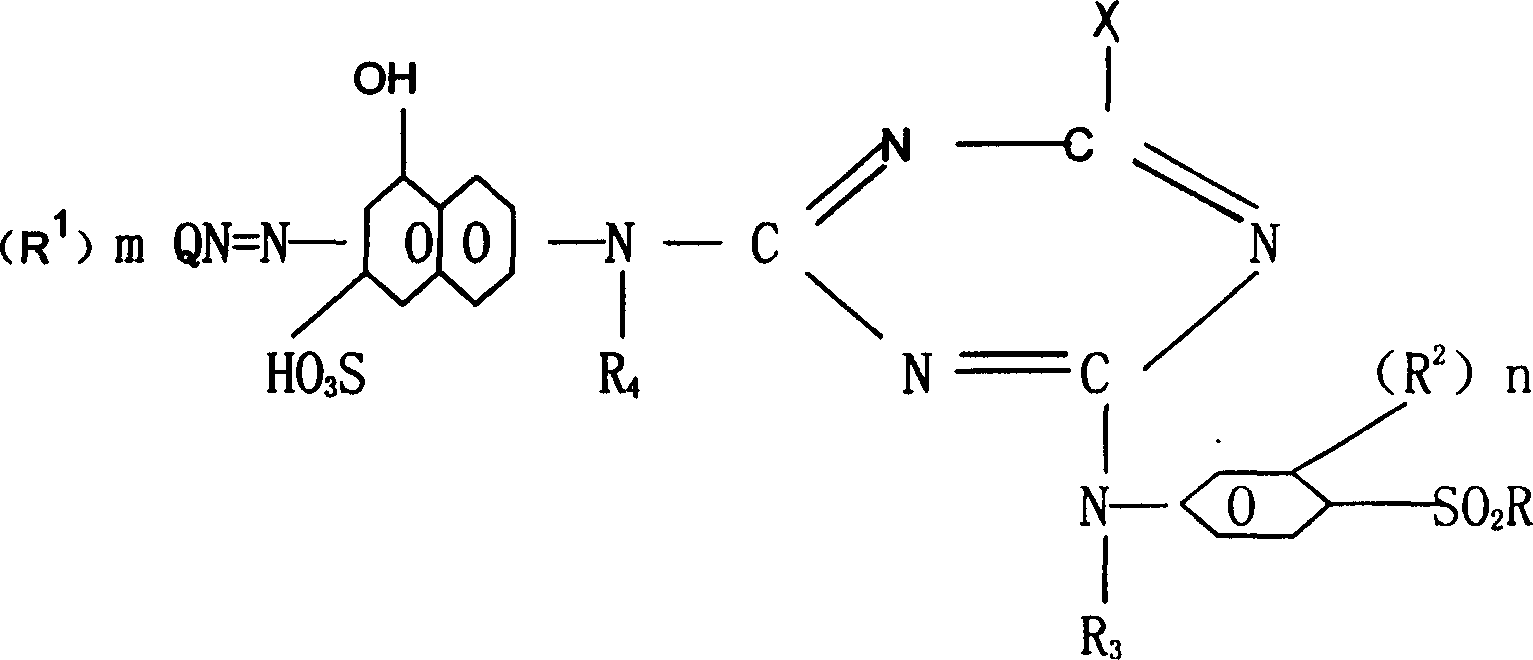

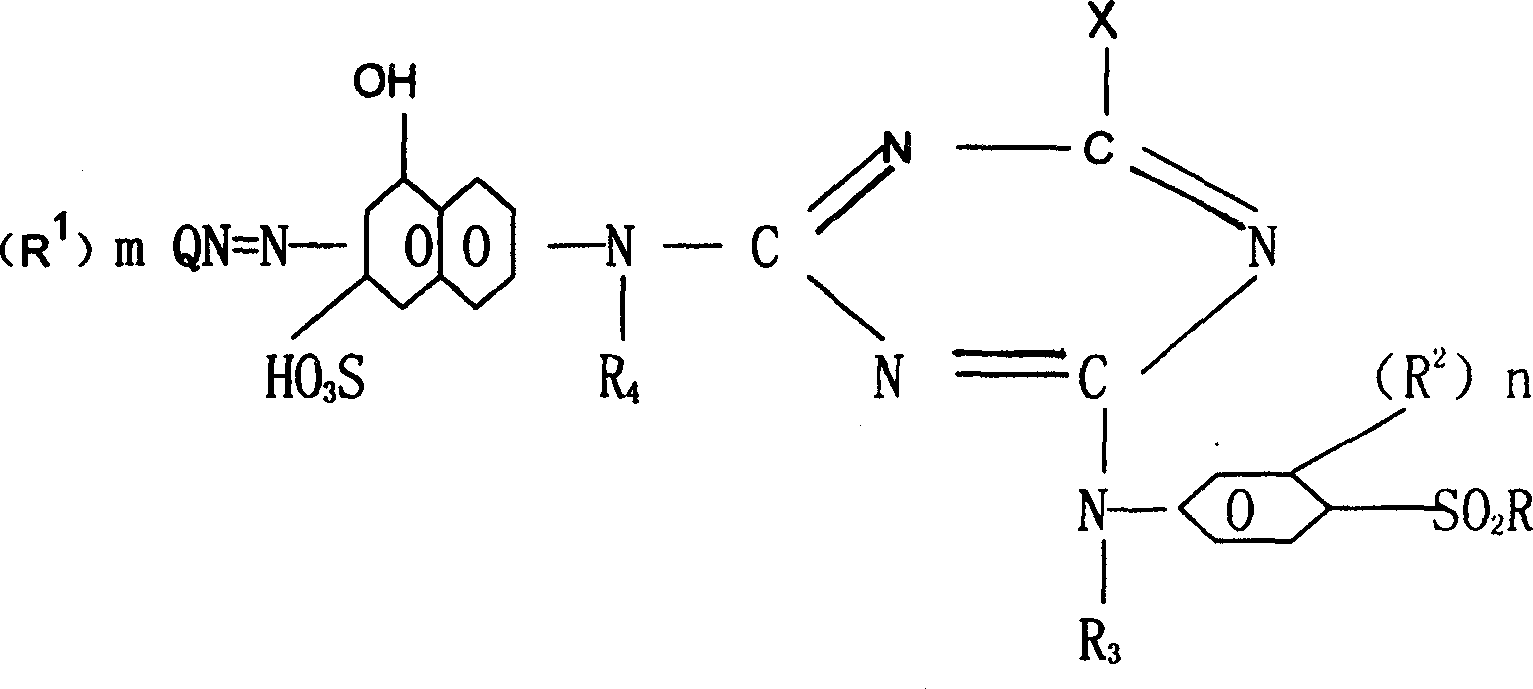

Image

Examples

Embodiment Construction

[0027] The following examples serve to illustrate the invention, temperatures are in degrees Celsius, and parts and percentages are by weight unless otherwise stated.

[0028] A kind of preparation technology of azo reactive dye, it comprises the following steps

[0029] 27-30.3 parts by weight of 2-amino-1,5-naphthalene disulfonic acid is added to form a diazonium salt component after adding 30-36.5 parts of hydrochloric acid and 5.4-6.9 parts of sodium nitrite;

[0030] 18-20 parts by weight of cyanuric chloride, 50 parts of water, 5 parts of disodium hydrogen phosphate, fully mixed with 0.1 part of wetting agent (wetting agent can effectively disperse and penetrate, such as SBO, acetone, etc.) To form a suspension, add 27 to 28.1 parts of 4-(β-hydroxyvinylsulfone sulfate) aniline solution dropwise to the suspension, and then add dilute sodium hydroxide solution to the suspension to keep the pH value of the suspension Between 3.5 and 4, keep reacting until the unreacted 4-(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com