Liquid cooling of mould for making glass utensils

A glassware and mold technology, applied in the field of mold cooling, can solve the problems of lack of thermal conductivity and thermal cycle cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

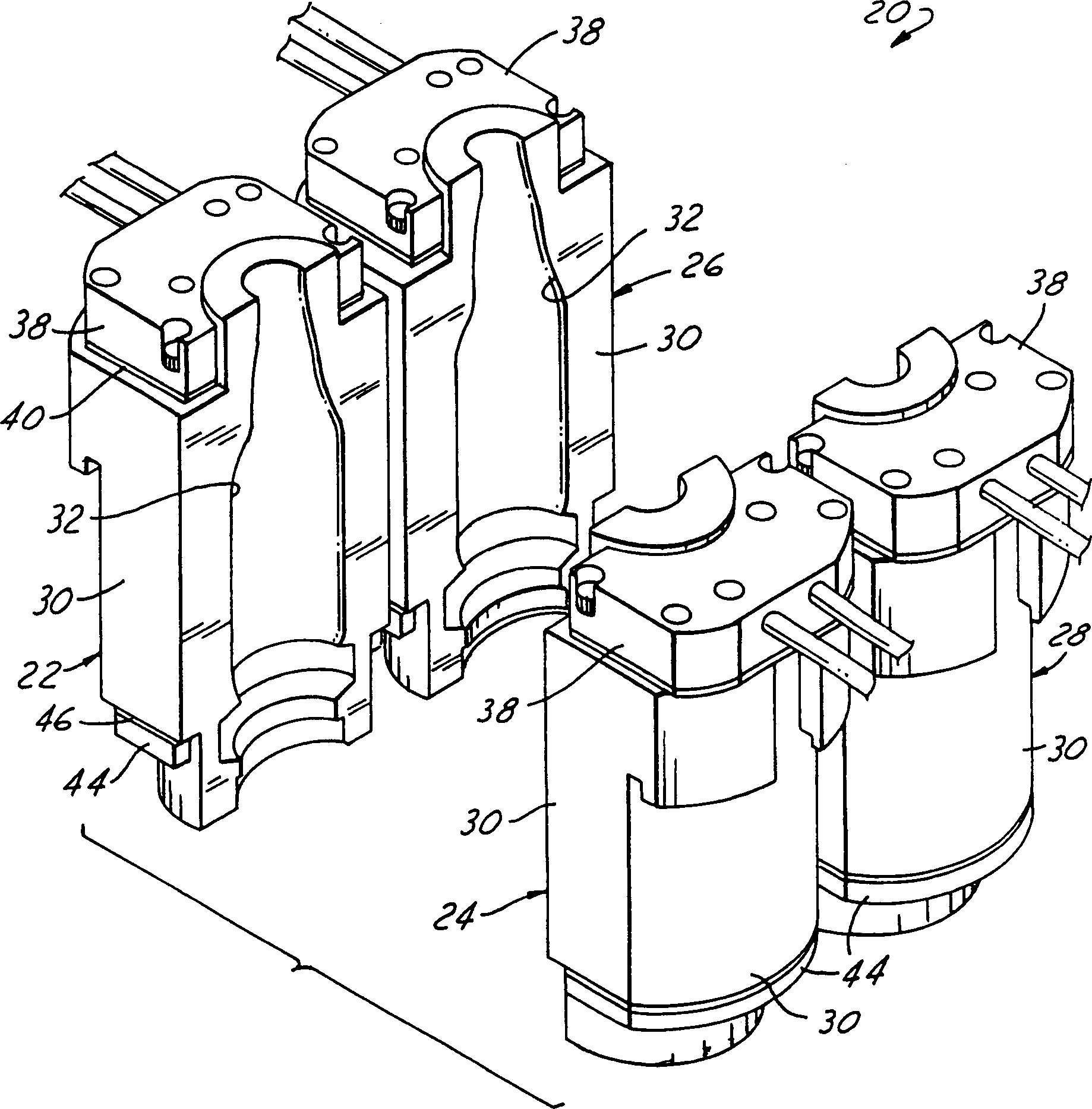

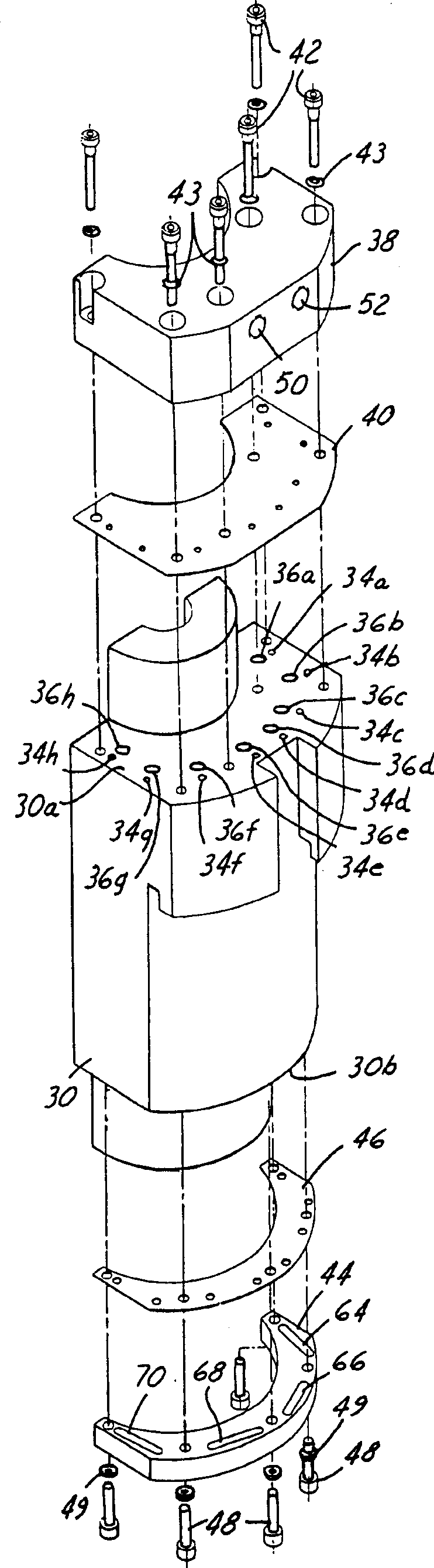

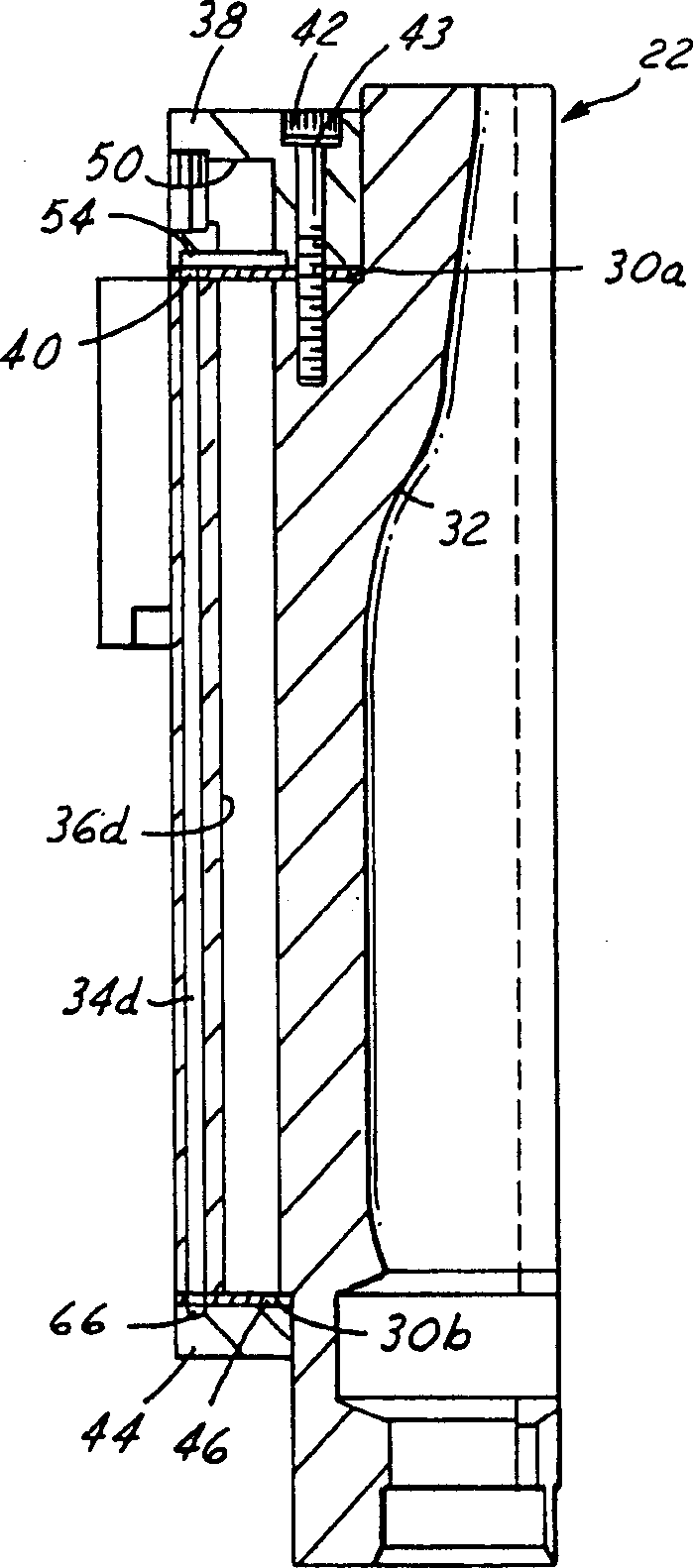

[0027] figure 1 Mold 20 is shown having a first pair of split molds 22, 24 and a second pair of split molds 26, 28, the illustrated modules 22-28 being blow molds for a dual zone bottle making machine (IS) . But the present invention is also equally applicable to the cooling of the blank mold ( Figure 16 ) combined application, and can be equally applied to other types of IS machine or rotary bottle making machine such as single machine, three machines and four machines. Each module 22-28 has a body and two opposing end plates. Combine below Figure 2-7 and 17 detailing module 22, it should be understood that module 26 is identical to module 22 and that modules 24, 28 are mirror images of module 22.

[0028]Mold 22 has a mold body 30 with a forming surface 32 in its central portion which, together with a corresponding forming surface of opposing mold 24, forms a surface for shaping molten glass during a pressing or blowing operation. Thus, the molten glass is in contact ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap