Multi-tube jetting oscillating refrigerator and its refrigeration method

A multi-tube, refrigerator technology, which is applied in the field of jet engineering and expansion refrigeration of pressurized gas, can solve the problems of reduced bearing pressure capacity and complex structure, and achieves the effects of strong adaptability, energy-saving structure and long operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

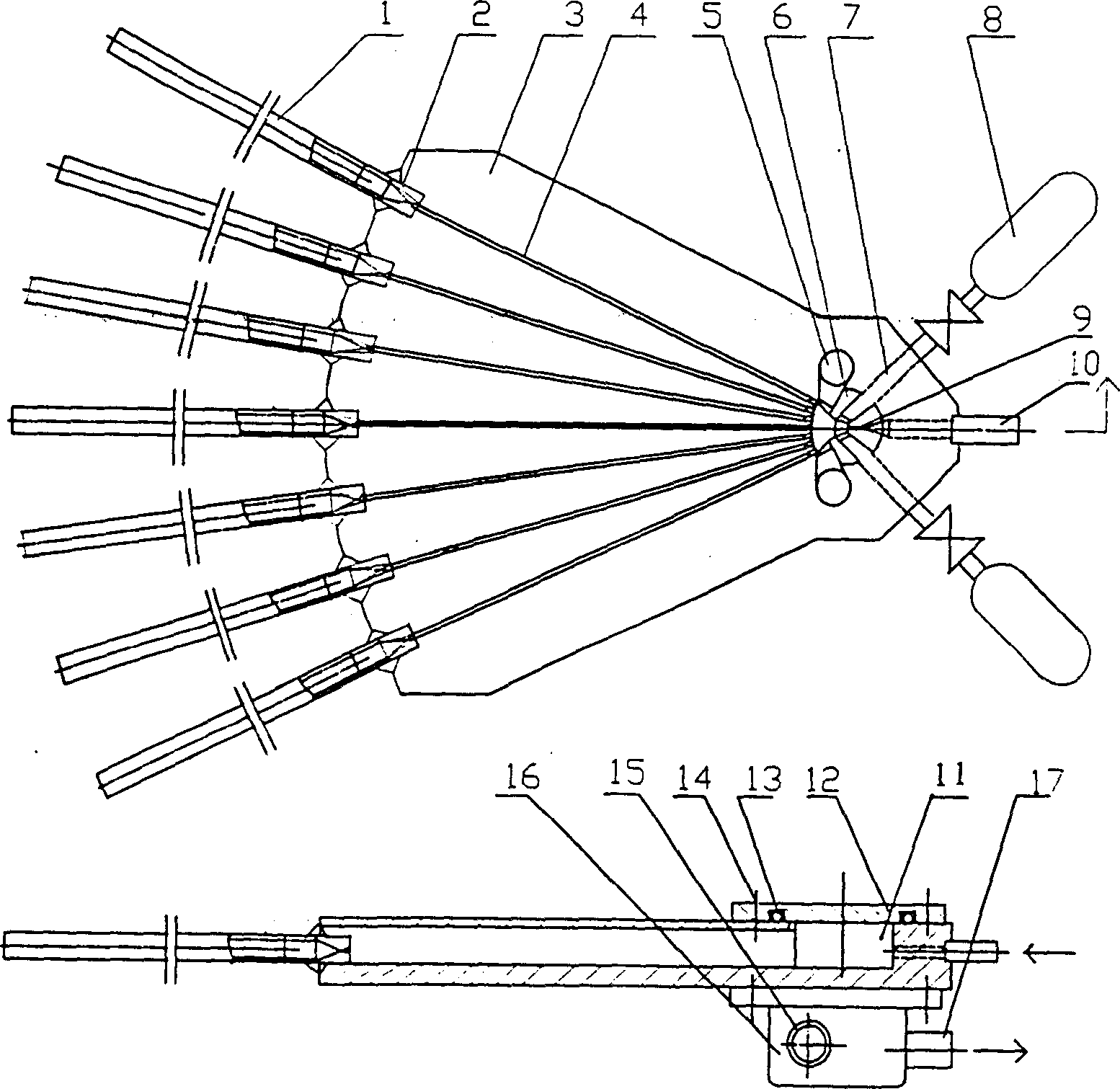

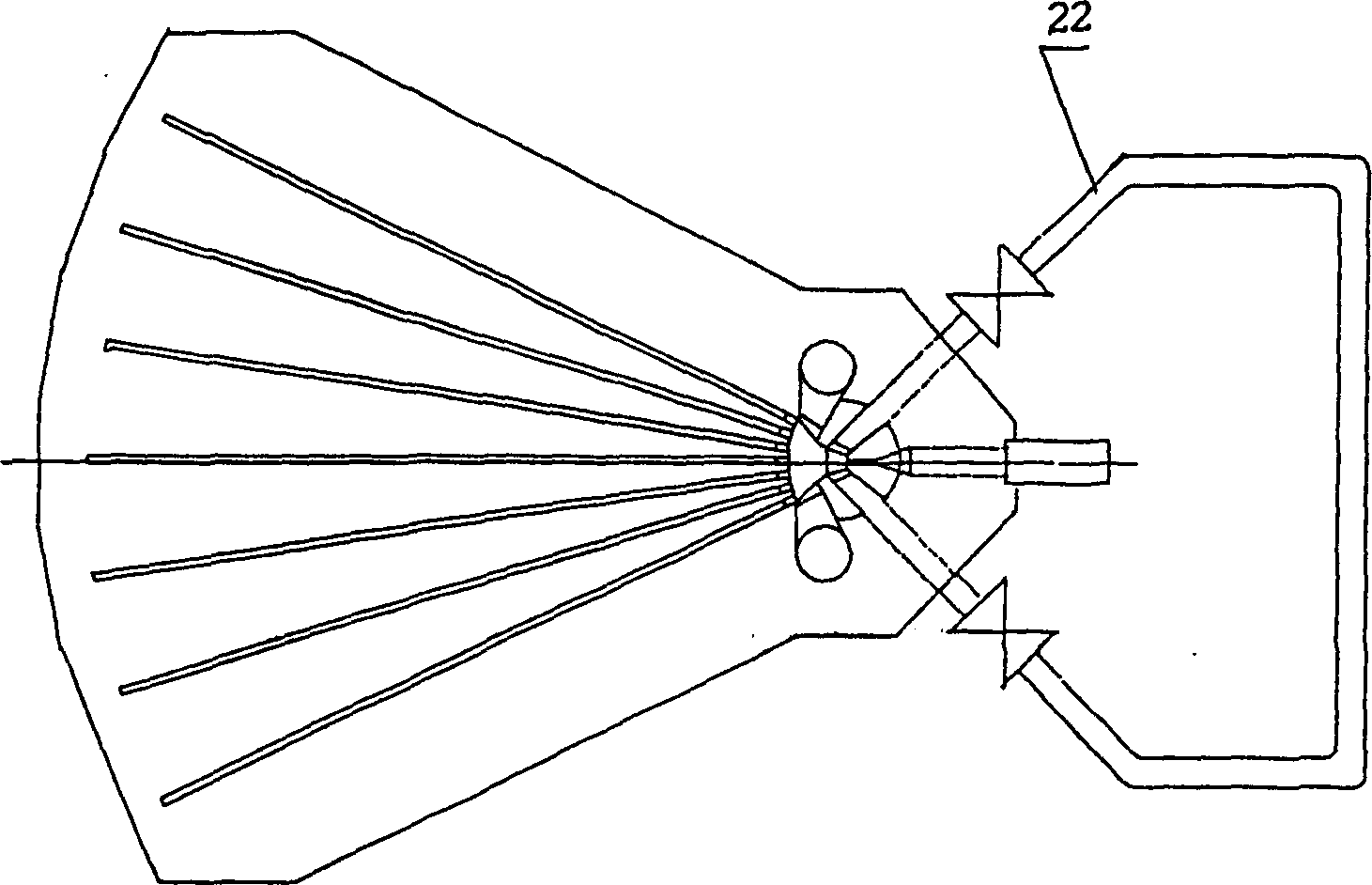

[0049] A multi-tube jet oscillation refrigerator mainly consists of a body (3), an oscillation receiving tube (1), a core (6), an acoustic oscillator (8), a jet nozzle (9) and the like.

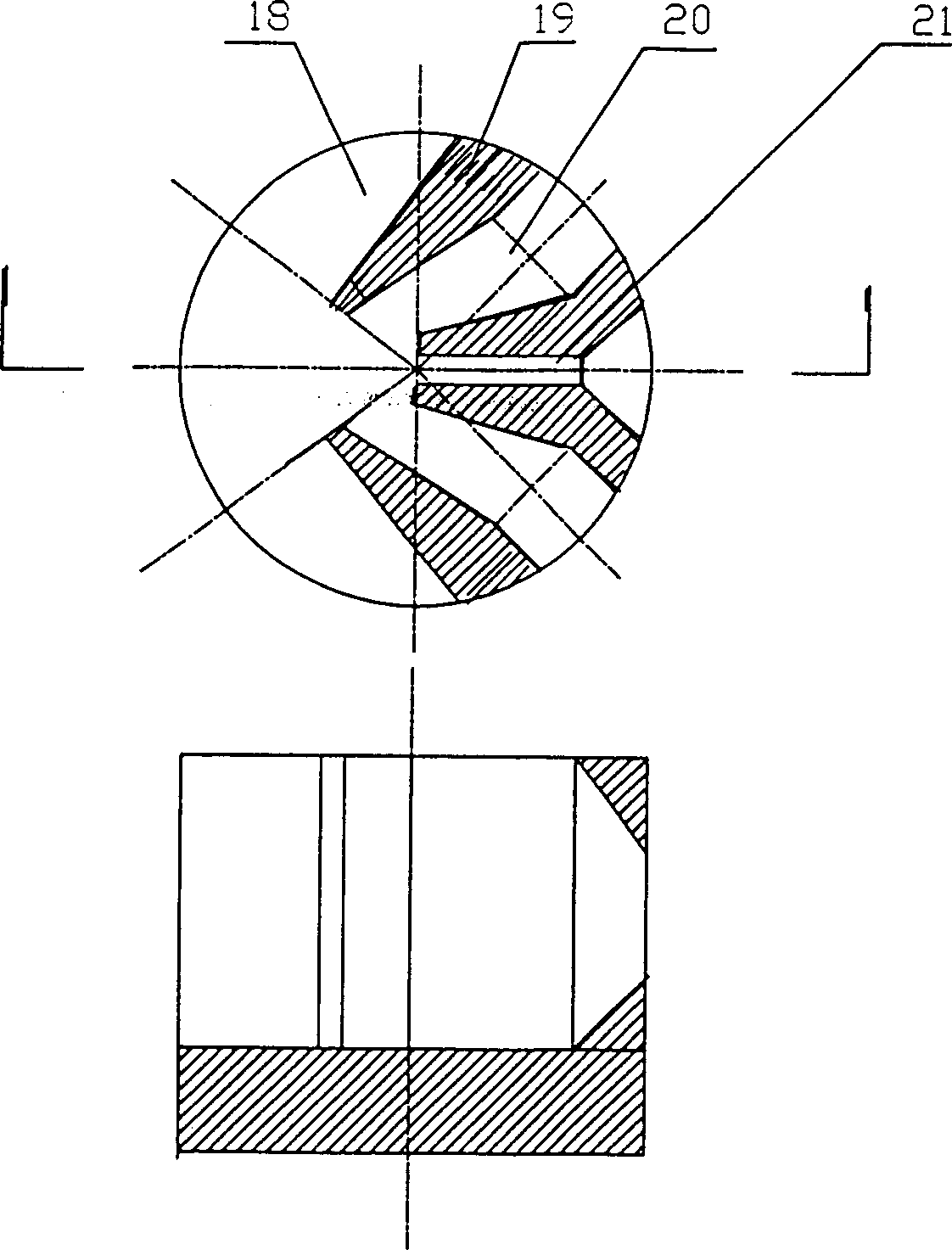

[0050] The body (3) is processed from a metal plate with a size of 100-120mm in thickness, and according to the size of the processing capacity, 3-15 metal plates with a length of 500-600mm, a width of 6-10mm, and a depth of The diameter is 60-80mm, and the cross-section is a rectangular jet flow channel (4). There is a stepped platform processed in the flow channel, which is specially used for positioning the inserts of the welding package flow channel, and to ensure the size of the flow channel. The overall distribution of the runners is divergent, the distance between the runners near the end of the core (6) is tapered, and the distance between the runners at the end of the injection area is generally 2mm, and the runners are sharply narrowed. This will help the jet nozzle (9) to fully unh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com