Fuel battery

A fuel cell and fuel gas technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as complex sealing structures, achieve uniform flow rates, improve power generation performance, and improve power collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

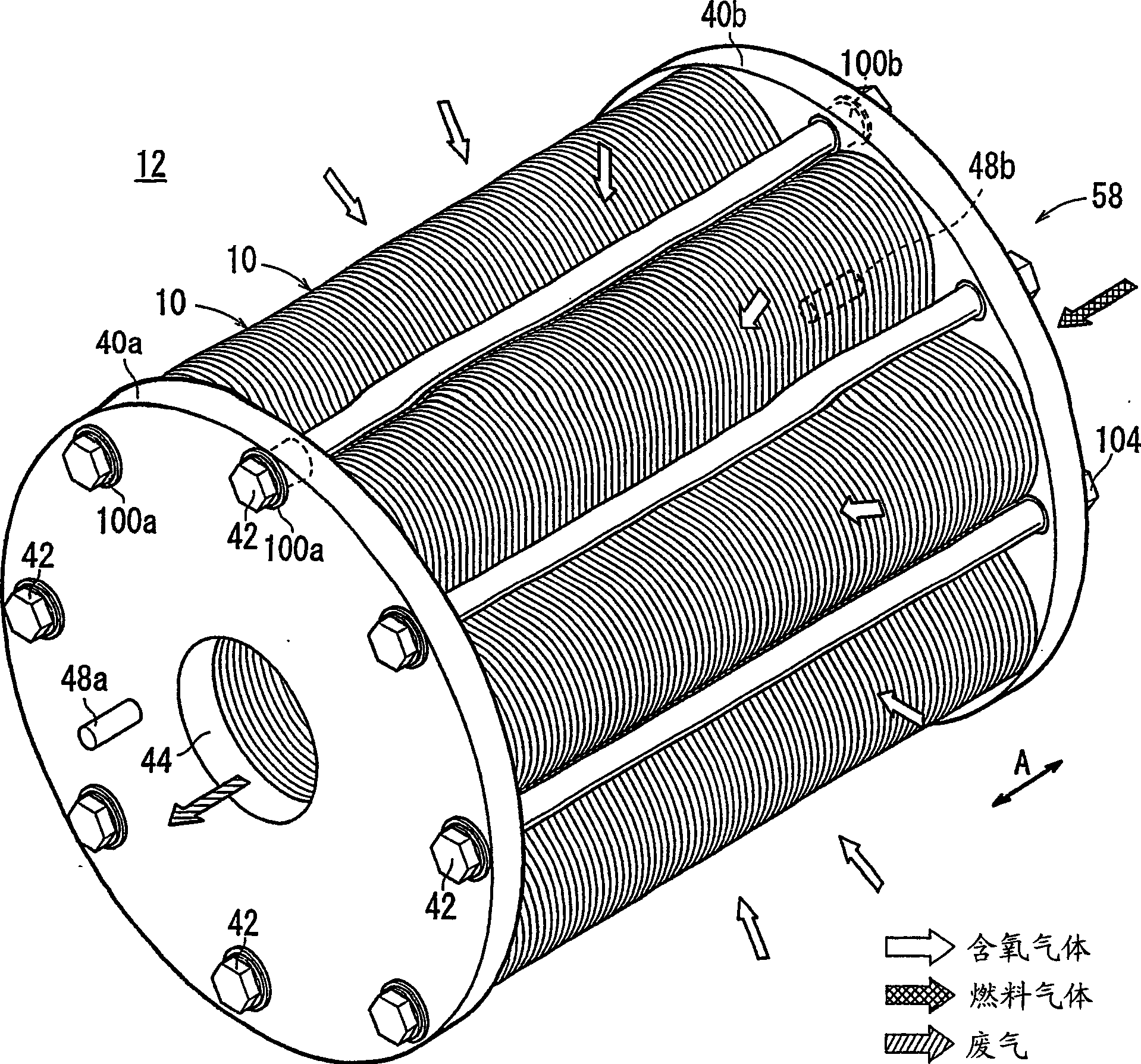

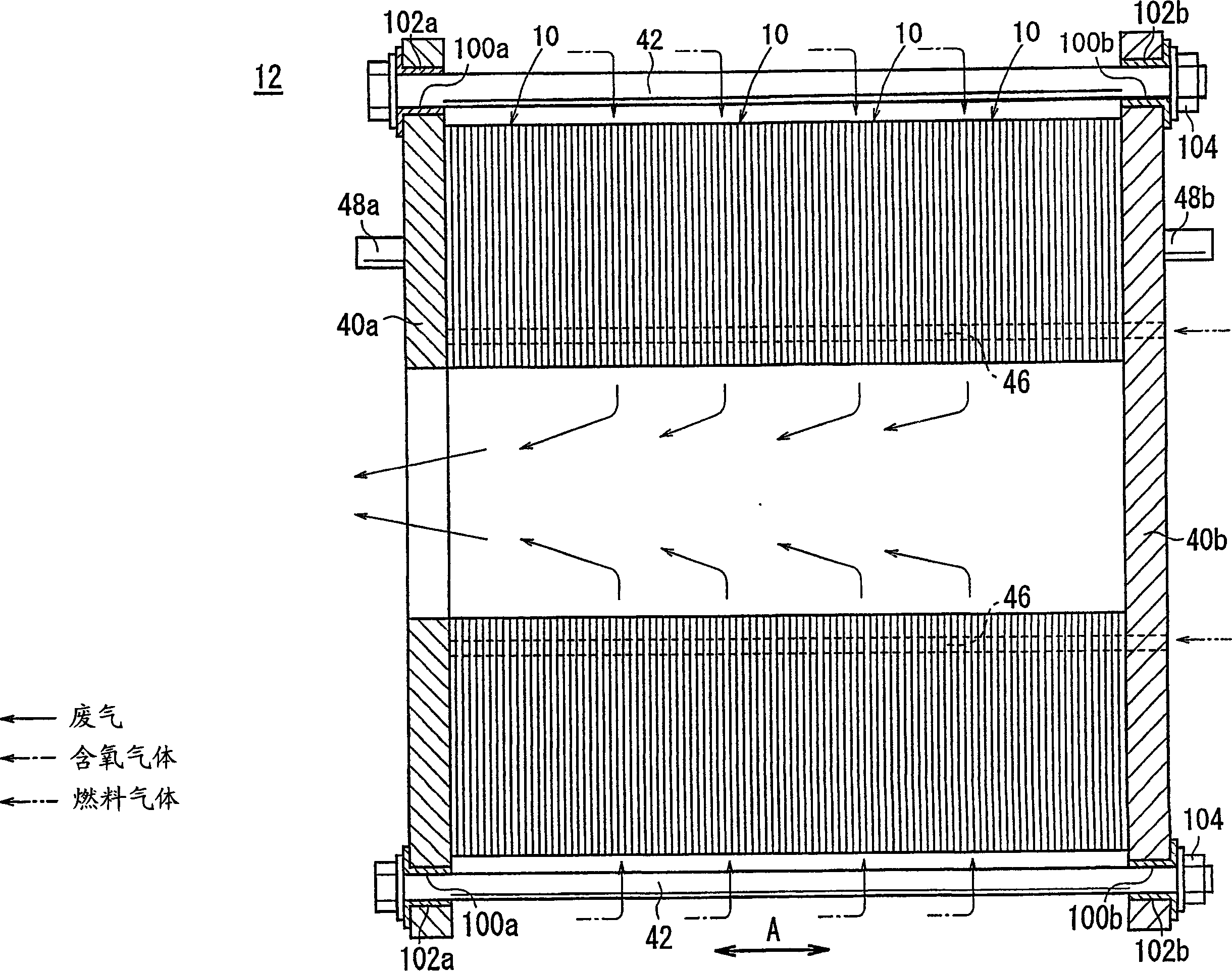

[0042] figure 1 is a perspective view schematically showing a fuel cell stack 12 formed by stacking a plurality of fuel cells 10 according to an embodiment of the present invention, and figure 2 A cross-sectional view of a part of the fuel cell stack 12 is shown.

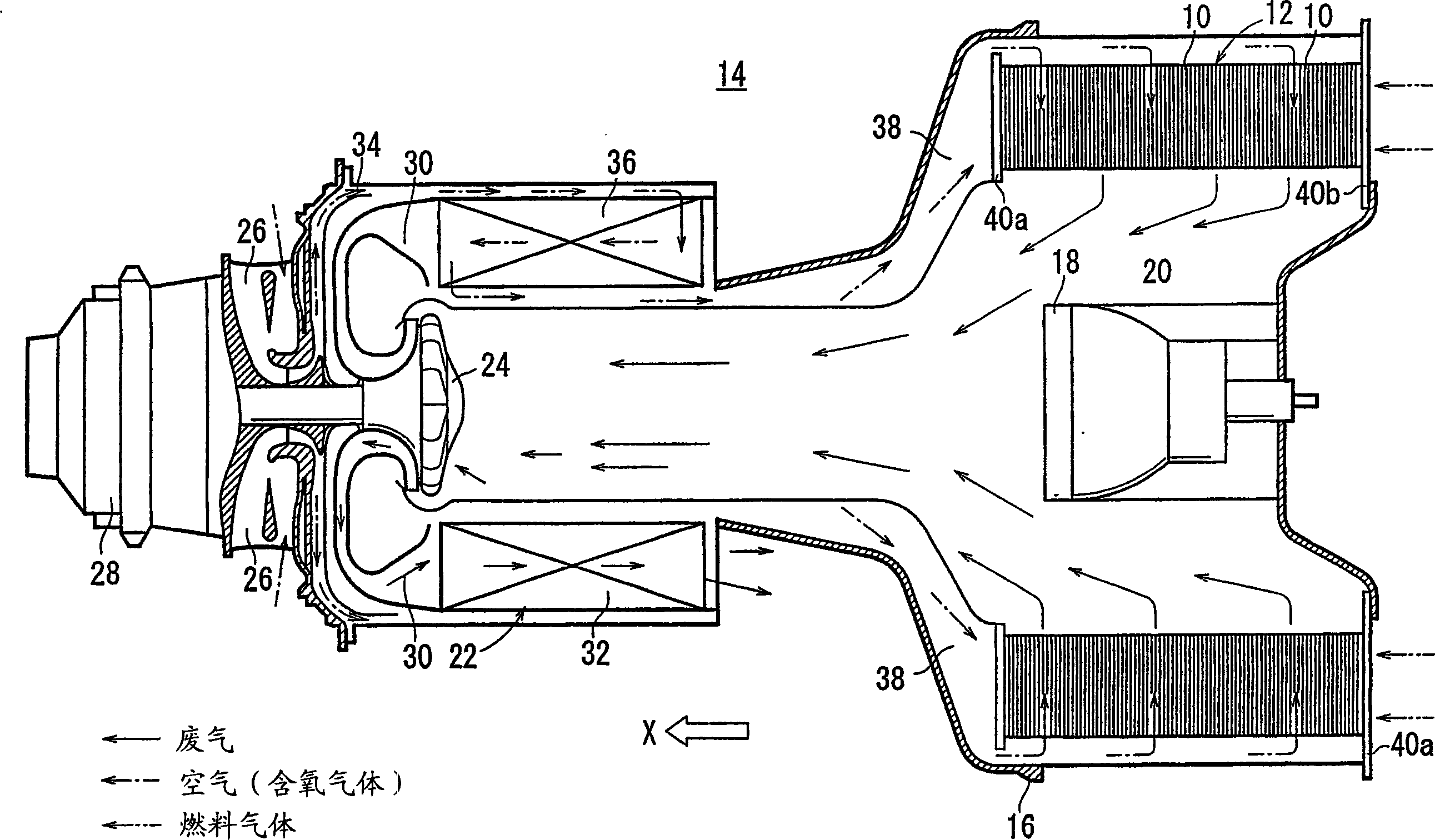

[0043] Fuel cell 10 is a solid oxide fuel cell (SOFC) for stationary and mobile equipment. For example, this fuel cell 10 is mounted on a motor vehicle. exist image 3 In the example of embodiment shown in , the fuel cell stack 12 is used in a gas turbine 14 . exist image 3 , the shape of the fuel cell stack 12 is the same as figure 1 and 2 The ones in are different, but the structure is basically the same.

[0044] The fuel cell stack 12 is disposed within a casing 16 of a gas turbine 14 . The burner 18 is provided at the center of the fuel cell stack 12 . The fuel cell stack 12 discharges the mixed gas of the fuel gas and the oxygen-containing gas after reaction into the chamber 20 toward the burner 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com