Fire-resisting sound-insulating safety door and its production method

A technology for safety doors and door shafts, which is applied to fire doors, soundproof doors/windows, etc., can solve the problems of overall strength decline, impact resistance, and insufficient safety, and achieve the effect of fast and convenient construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

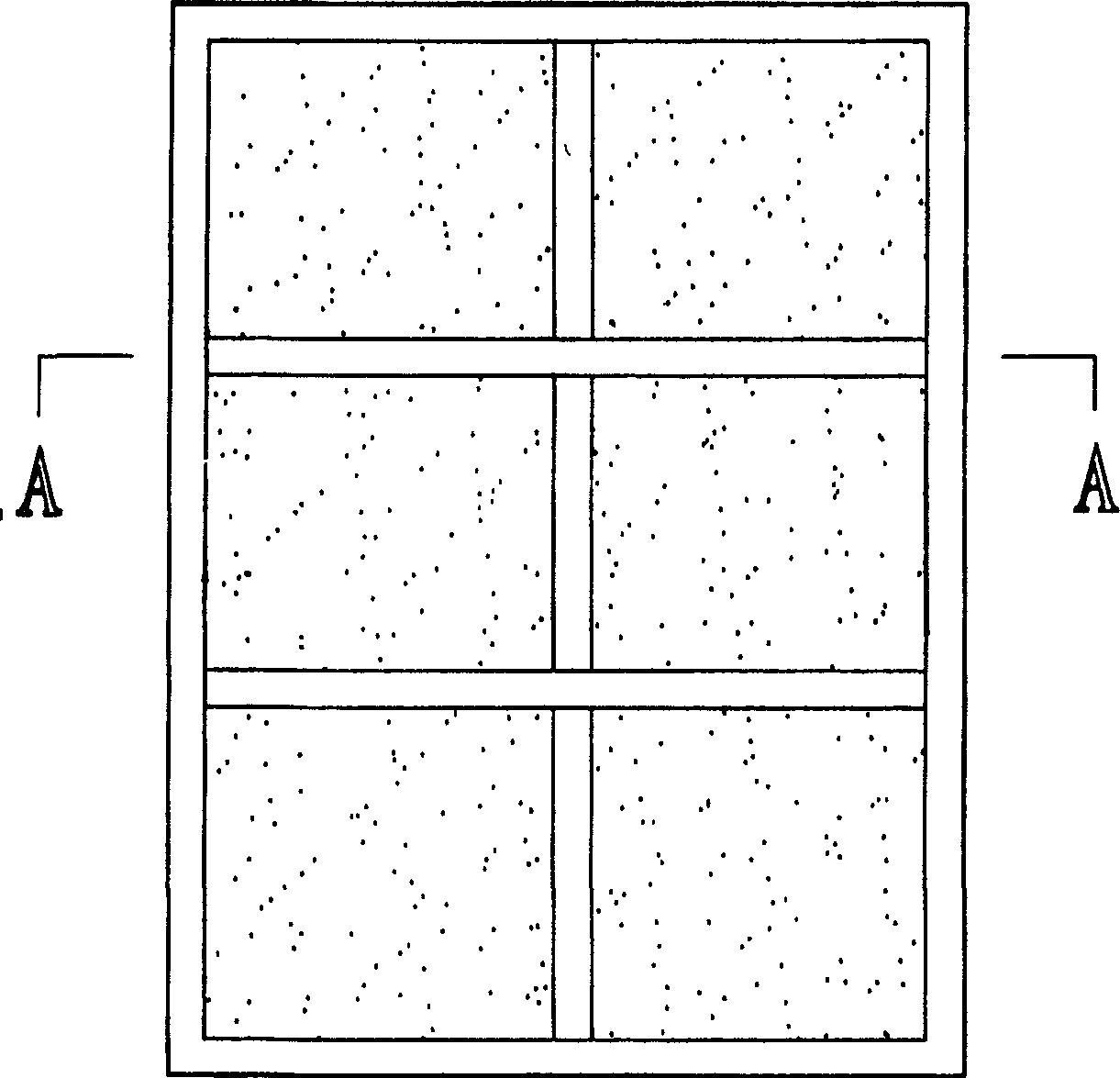

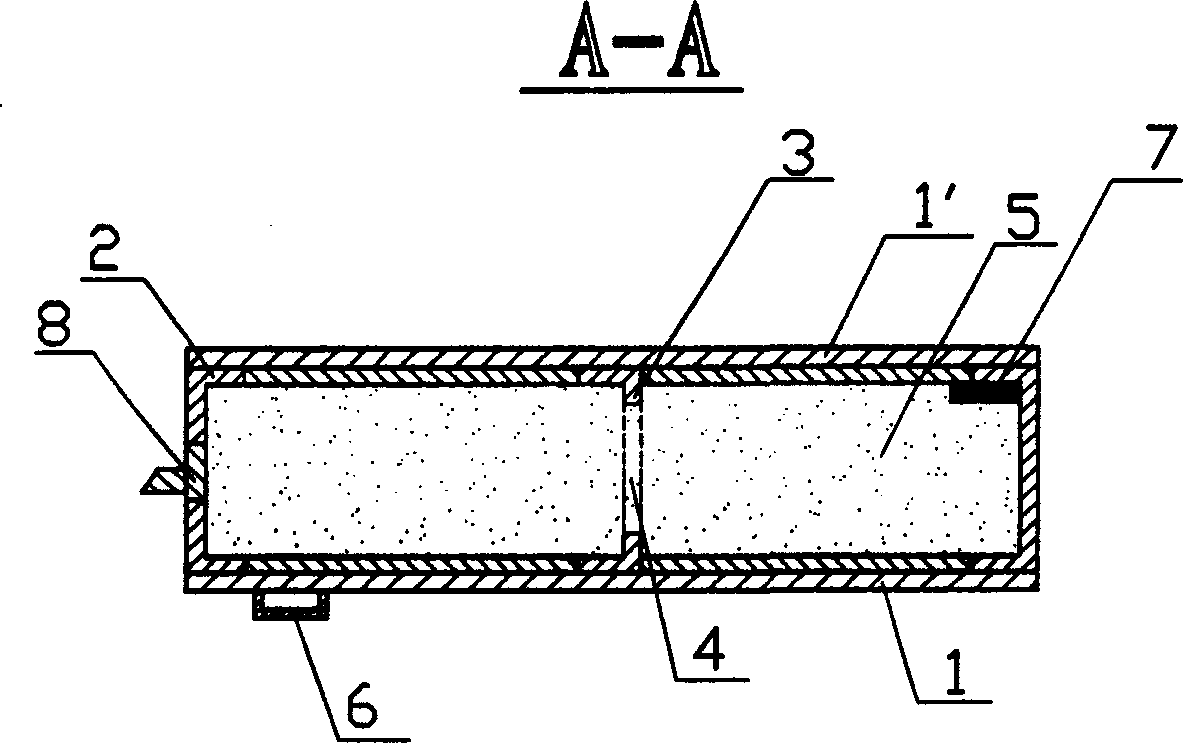

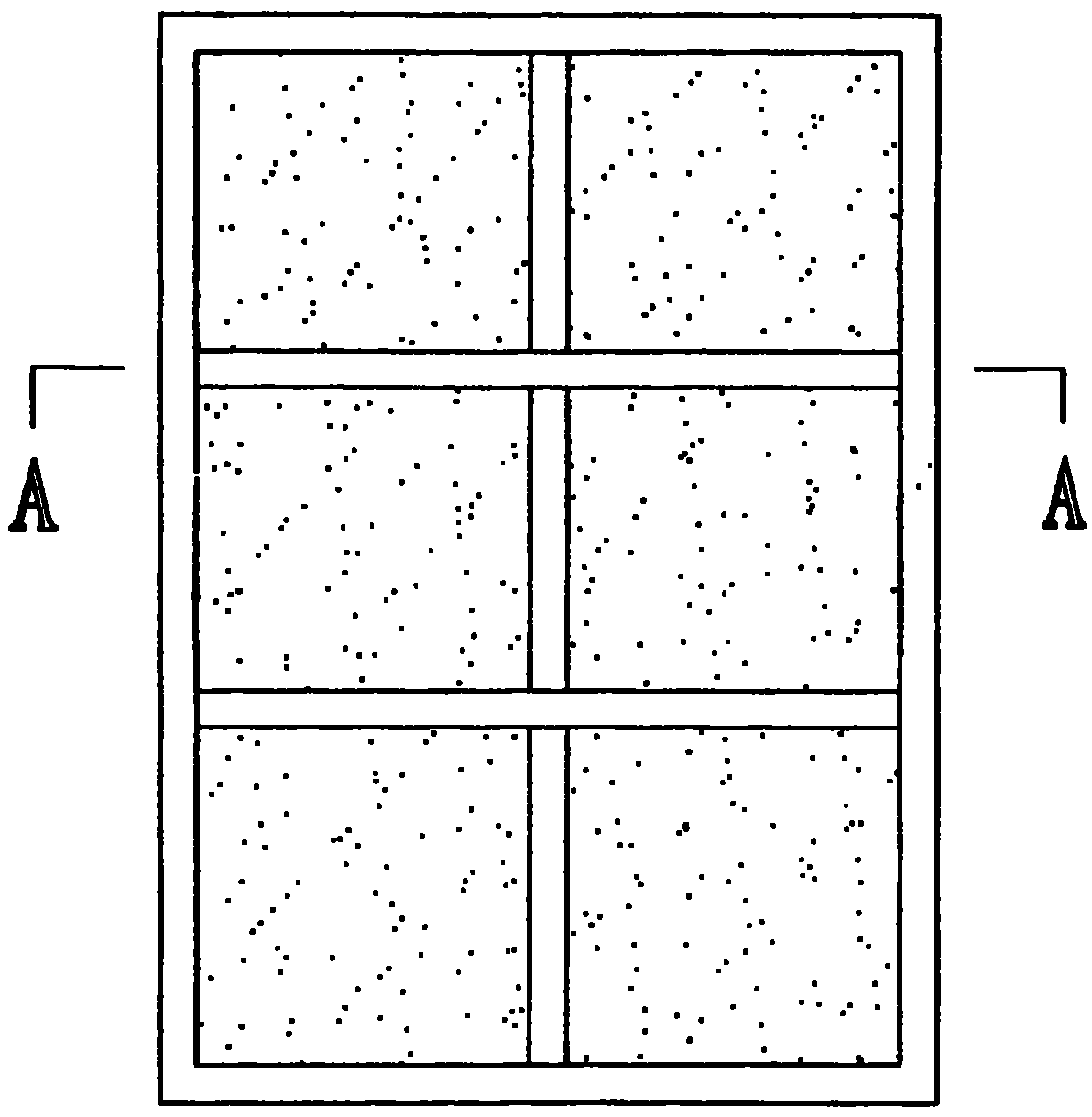

[0030] Such as figure 1 , figure 2 As shown, the fireproof and soundproof safety door of the present invention mainly consists of steel plates 1, 1 ', steel frame 2 and reinforcing rib 3, and is characterized in that two steel plates 1, 1 ' are arranged on both sides of the steel frame 2; And there are several reinforcing ribs 3 between the two steel plates 1, 1', and they are firmly connected with the steel plates as a whole; on the reinforcing ribs 3, there are several foam cement penetrable A hole 4; a foam cement filler 5 is provided in the steel frame; a door handle 6 and a door shaft reinforcement 7 are provided on the safety door; and a door lock device 8 is provided.

[0031] The manufacturing method of the present invention comprises:

[0032] 1. First connect the steel frame 2, two steel plates 1, 1' and the reinforcing rib 3 with the hole 4 firmly into a whole; and place it on the mold;

[0033] 2. After stirring the cement slurry evenly according to a certain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com