Organic/laminated, layer-chain clay mineral nano composite energy-storage material and its preparing method

A clay mineral and nanocomposite technology, applied in the field of energy storage materials, can solve the problems of low energy storage density and achieve stable energy storage performance, convenient operation, and high phase change enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, the layered or layered chain clay mineral is organic montmorillonite, the organic solid-liquid phase change energy storage material is paraffin, and the weight ratio of paraffin in the composite energy storage material is not more than 60%.

[0019] The preparation process is:

[0020] a. Add 14g of paraffin to 10g of organic montmorillonite with a particle size of <76μm, and mix well;

[0021] b. Heat to 80°C to make the paraffin wax melt, and keep stirring in this state to fully mix it until it is completely compounded;

[0022] c. Cool to room temperature to obtain the paraffin / montmorillonite composite energy storage material.

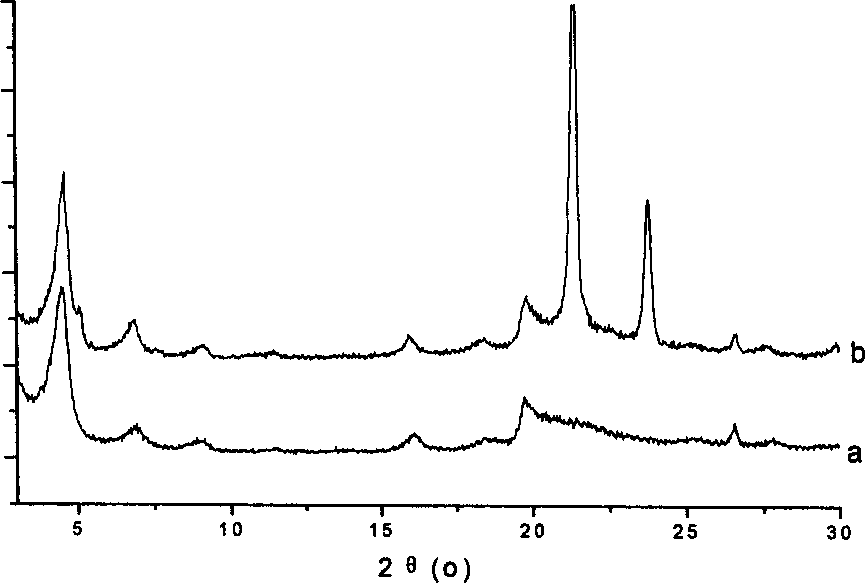

[0023] As shown in Figure 1, comparing the X-ray diffraction patterns of paraffin / montmorillonite composite energy storage materials and organic montmorillonite, it can be seen that after intercalation compounding, the interlayer distance of montmorillonite changes from 19.708 Ȧ to 19.447 Ȧ, which is It shows that the p...

Embodiment 2

[0028] In this embodiment, the organic clay mineral is organic montmorillonite, the organic solid-liquid phase change energy storage material is stearic acid, and the weight ratio of stearic acid in the composite energy storage material is not more than 75%.

[0029] The preparation process is:

[0030] a. Add 25g of stearic acid to 10g of organic montmorillonite with a particle size of <76 μm, and mix well;

[0031] b. Heat to 80°C to make the stearic acid melt, and keep stirring in this state to make it fully mixed until it is completely compounded;

[0032] c. Cool to room temperature to obtain the stearic acid / montmorillonite composite energy storage material.

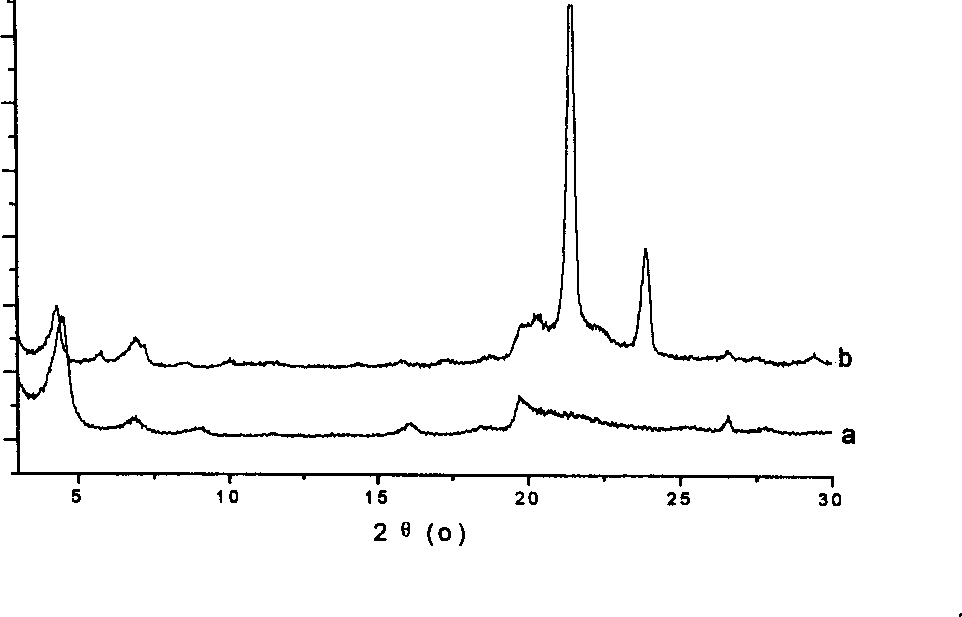

[0033] X-ray diffraction pattern such as figure 2 shown by figure 2 It can be seen that after intercalation compounding, the interlayer spacing of montmorillonite changes from 19.708 Ȧ to 20.532 Ȧ, which indicates that stearic acid molecules enter the interlayer of montmorillonite, causing the interlayer spacing...

Embodiment 3

[0038] In this embodiment, the organic clay mineral is organic montmorillonite, the organic solid-liquid phase change energy storage material is lauric acid, and the weight ratio of lauric acid in the composite energy storage material is not more than 70%.

[0039] The preparation process is:

[0040] a. Add 24g of lauric acid to 10g of organic montmorillonite with particle size <76μm, and mix well;

[0041] b. Heat to 70°C to make the lauric acid melt, and keep stirring in this state to make it fully mixed until it is completely compounded;

[0042] c. Cool to room temperature to obtain the lauric acid / montmorillonite composite energy storage material.

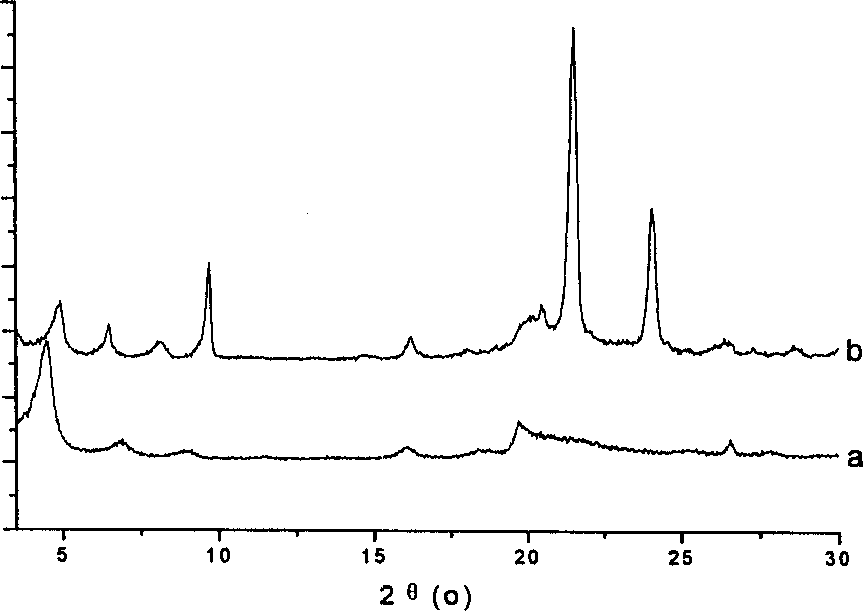

[0043] Its X-ray diffraction pattern is as image 3 shown, from image 3 It can be seen that after intercalation compounding, the interlayer spacing of montmorillonite changes from 19.708 Ȧ to 17.946 Ȧ, which indicates that lauric acid molecules enter the interlayer of montmorillonite, causing the interlayer spacing to cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com