Method for producing sugar-free tea beverage by using high voltage pulsation electric-field sterilizing technology

A high-voltage pulsed electric field, tea beverage technology, applied in the application, tea extraction, food preservation and other directions, can solve the problems of turbidity of tea beverages, unsatisfactory clarification of tea juice, unable to completely solve the problem of turbidity and sedimentation, and achieve simple process and high-efficiency filtration. Turbidity removal method, good turbidity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 sugar-free green tea beverage preparation

[0026] Because the production processes of green tea, black tea and oolong tea are very similar, and green tea beverages are most prone to browning and turbidity during preparation, the production of green tea beverages is used as an example here.

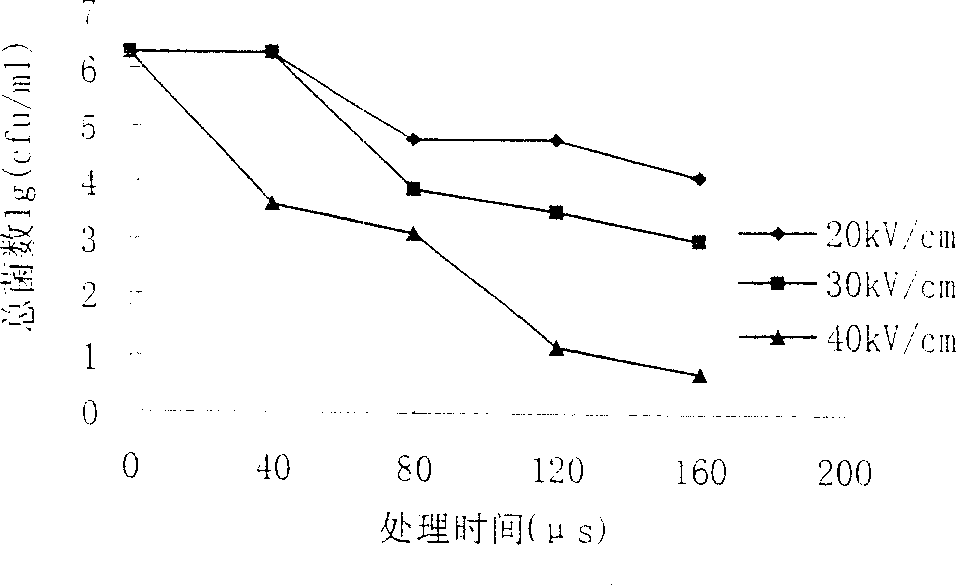

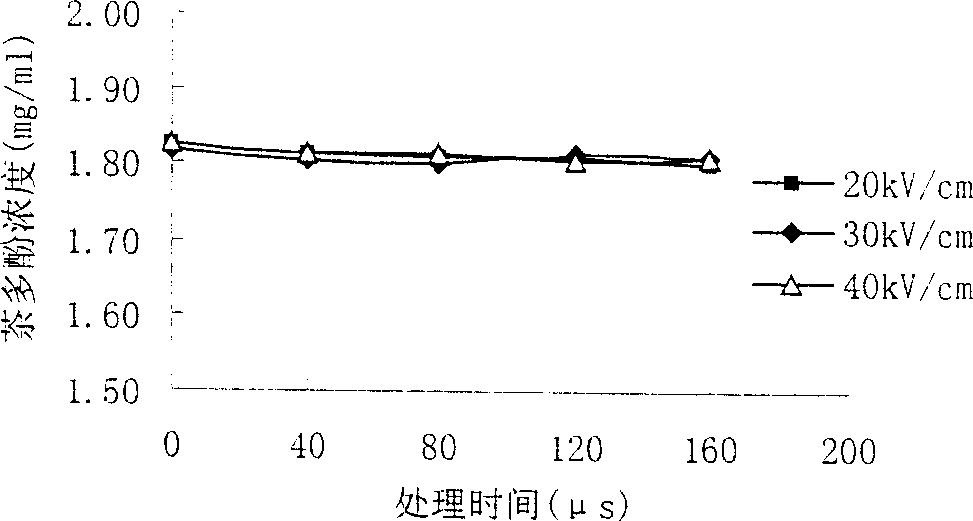

[0027] Using commercially available fried green tea leaves as raw materials, 5ppm Ko-cyclodextrin and 5ppm ZnCl have been added 2 The color-protecting agent was leached in hot water at 50°C for 20 minutes. The extracted tea soup is filtered through a 200-mesh sieve, and then cooled rapidly to below 10°C. The cooled tea soup was centrifuged at 3000r / min for 15min, and suction filtered. Filter the tea soup through a 05 μm microporous filter to obtain a clear and transparent tea soup. Part of the tea soup was inoculated with Escherichia coli, and the bacterial concentration reached 106 level, which was used for bactericidal research. The inoculated and non-inoculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com