Method for continuous preparation of nanometer-sized hydrous zirconia sol

A technology of hydrated zirconia and zirconium sol, which is applied in the field of junction and can solve the problem of not being able to provide hydrated zirconia sol and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

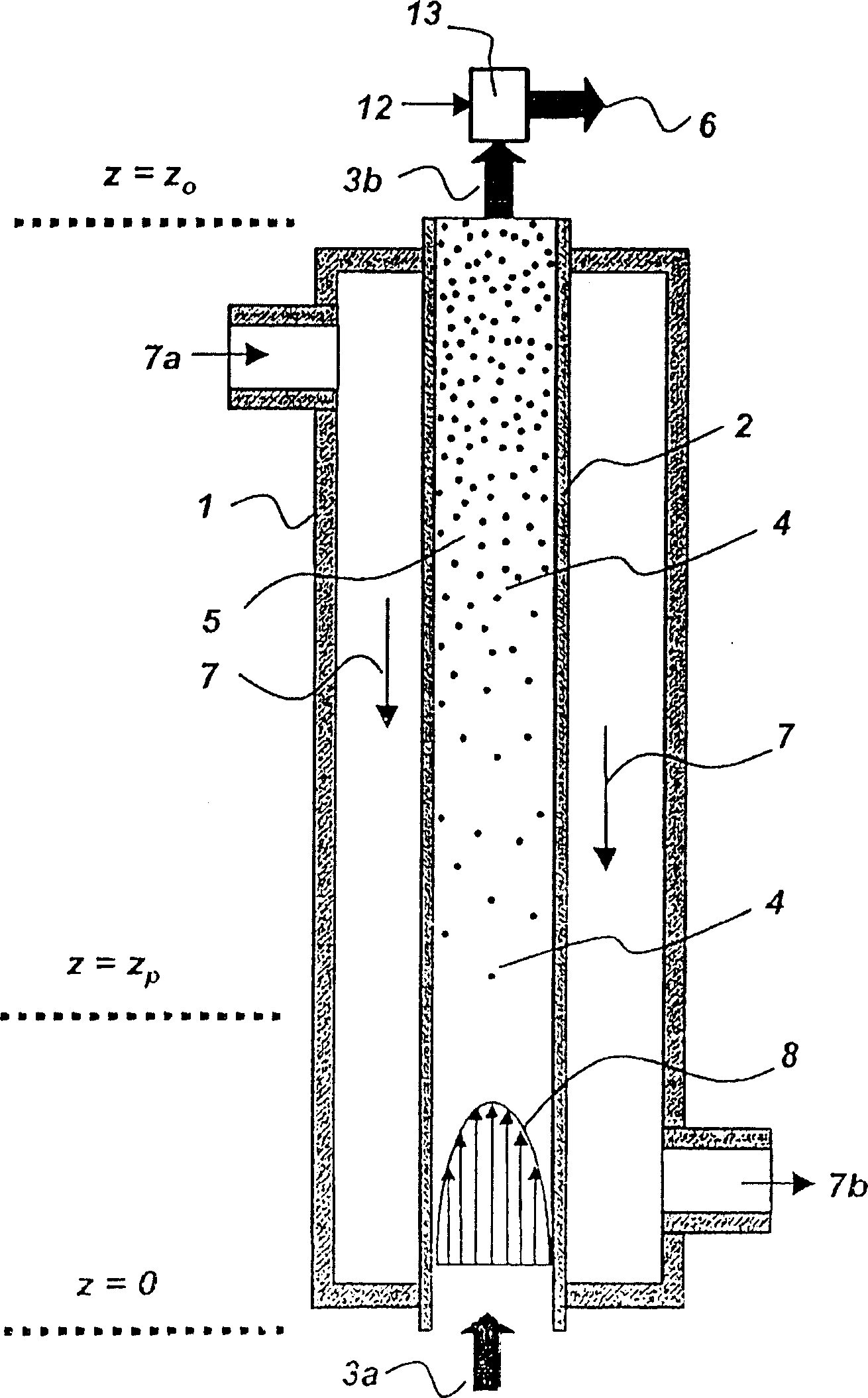

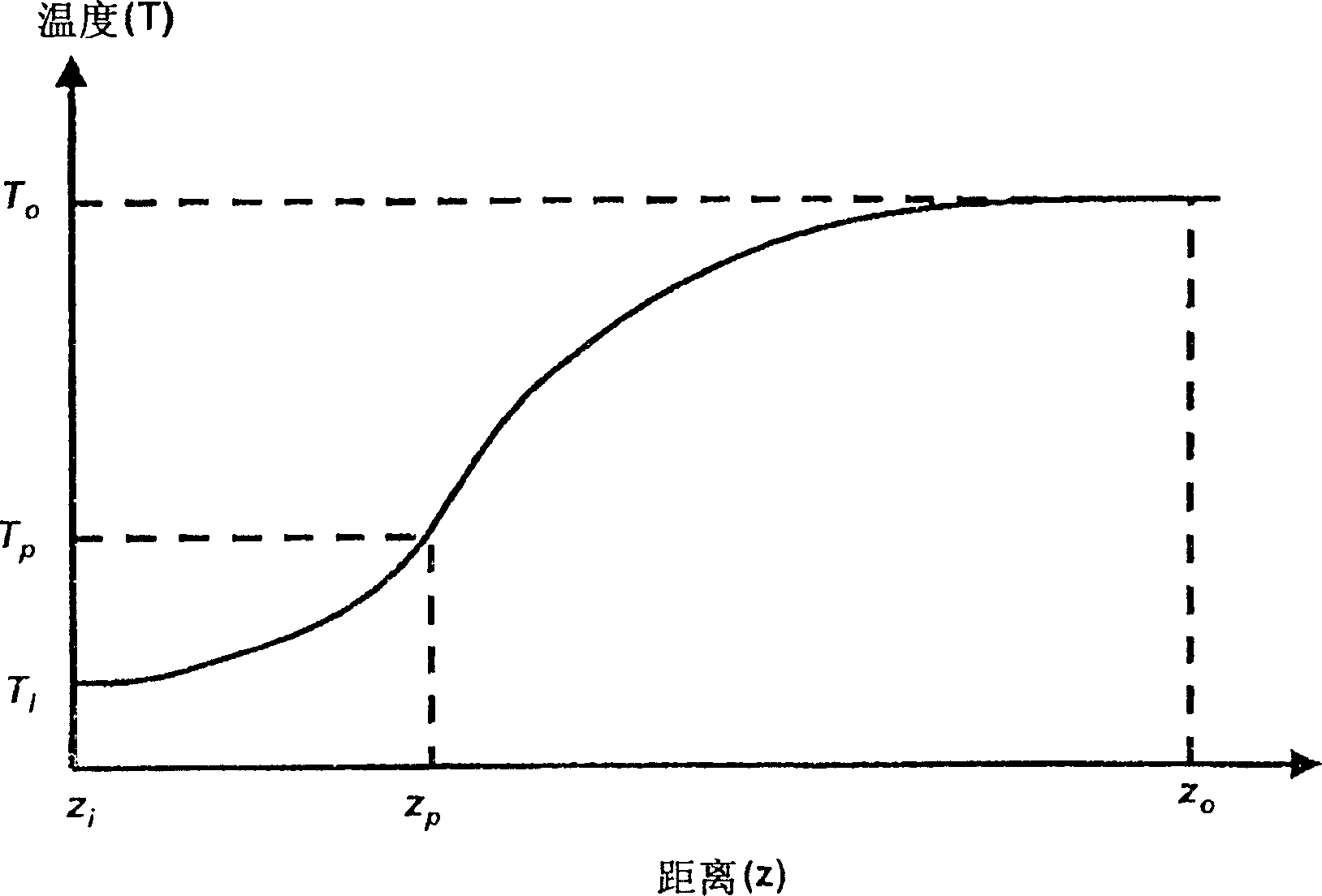

Method used

Image

Examples

Embodiment 1

[0103] 0.2 mol of zirconium oxychloride and 1 g of hydroxypropylmethylcellulose were dissolved in 1 liter of a solvent mixture of 2-propanol and water (molar ratio 0.94) to prepare a zirconium saline aqueous solution. Such as Figure 5b As shown, two spiral type reaction tubes each having an inner diameter of 9.5 mm and a length of 5 m and composed of Pyrex glass were installed in a stainless steel vessel to form a condenser type tube reactor. The zirconium salt aqueous solution was supplied to the reaction tube at a flow rate of 403 cc / min at a temperature of about 10°C. A vapor-phase heating medium composed of hot water and ethanol (molar ratio 1:1) was supplied to the inside of the reactor (outside of the reaction tube) at a temperature of 98°C, and then condensed there. As a result, the outlet temperature of the reaction tube could be 74°C. The pH value of the suspension discharged from the outlets of the two reaction tubes was controlled to 9.1 by adding 0.8 N ammonia w...

Embodiment 2

[0108] 0.04 mol of zirconium oxychloride and 0.6 g of hydroxypropyl cellulose were dissolved in 1 liter of a solvent mixture of 1-propanol and water (1.7 molar ratio) to prepare a zirconium salt aqueous solution. Such as Figure 7a As shown, a 37 stainless steel reaction tube with an inner diameter of 3.37 mm and a length of 500 mm forms a shell-tube heat exchange type tubular reactor. An aqueous zirconium salt solution was fed to the reaction tube at a total flow rate of 1150 cc / min at a temperature of about 8°C. A vapor-phase heating medium obtained by heating 2-propanol was supplied to the shell (outside of the reaction tube) of the reactor at a temperature of 84° C., and then condensed there. As a result, the outlet temperature of the reaction tube could be 78°C.

[0109] The hydrated zirconia sol was continuously prepared by adding and mixing 2.0N ammonia water in the discharge pipe of the suspension mixer to control the pH to 5.6.

[0110] Five (5) drops of the result...

Embodiment 3

[0112] 0.2 mol of zirconium oxychloride and 7 g of polyvinyl alcohol were dissolved in 1 liter of a solvent mixture of 2-propanol and water (0.94 molar ratio) to prepare a zirconium salt aqueous solution. Such as Figure 4 As shown, the tubular reactor used had three (3) straight stainless steel tubes of concentric annular cross-section, 300 mm in length, and gauges of 1 / 4 inch, 3 / 8 inch, and 3 / 4 inch, respectively. The zirconium salt aqueous solution was fed to the concentric annulus of the 1 / 4 inch and 3 / 8 inch reaction tubes at a temperature of about 8°C at a flow rate of 30 cc / min. The hydrocarbon-based heat carrier oil heated to 95°C is simultaneously fed into the 1 / 4 inch pipe and between the 3 / 8 inch pipe and the 3 / 4 inch pipe against the flow direction of the zirconium salt aqueous solution, so as to have a concentric The temperature of the suspension at the outlet of the reaction tube of circular cross-section may be 82°C. The suspension was contacted with ammonia g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com