Method for preparing glass optical fiber prefabricated stick

A glass optical fiber, preform technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high production cost, large interface loss, short production time, etc., to avoid secondary wire drawing process, reduce interface loss, improve contact performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method for preparing an optical fiber preform, comprising the following steps:

[0014] (1) The cladding glass is melted by a conventional method, and the hollow tubular optical fiber cladding body is obtained by precision machining after annealing;

[0015] (2) Preheating the hollow tubular optical fiber cladding body at 400°C for 2 hours;

[0016] (3) After the core glass is melted, it is poured into the preheated hollow tubular optical fiber cladding body and annealed to obtain a glass optical fiber preform.

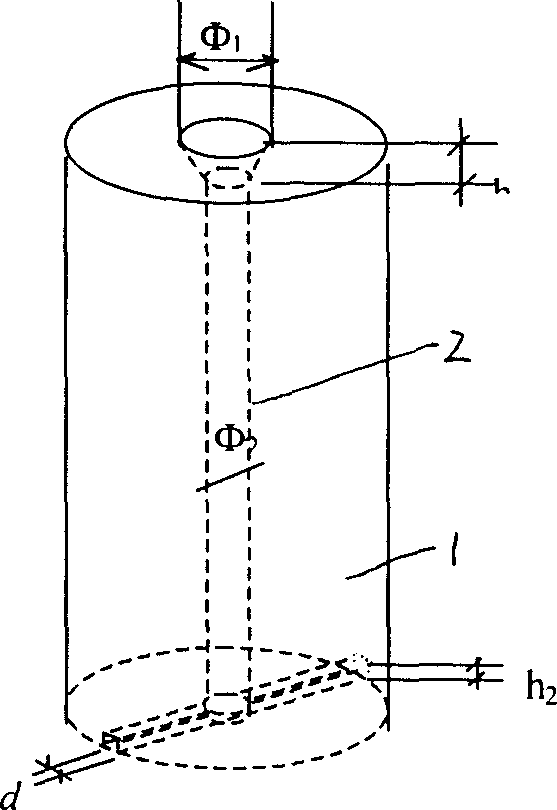

[0017] The hollow tube of the above-mentioned hollow tubular optical fiber cladding body is a top diameter Φ 1 = 8mm, height h 1 = 4mm tapered sprue, the bottom end of the hollow tube is width d = 2mm, height h 2 = 2mm exhaust channel, the middle of the cladding body is diameter Φ 2 = 5 mm hollow tube.

[0018] figure 2 It is the end view of the tellurite optical fiber drawn by the new process of this embodiment. It can be seen that the cladding and th...

Embodiment 2

[0020] A method for preparing an optical fiber preform comprises the following steps: interface loss is the key to reducing optical fiber loss. Moreover, the processing amount of the preform prepared by the tube and rod method is relatively large, which is time-consuming and material-intensive, and the requirements for the mechanical processing performance of the glass are also relatively high. It is difficult to use the tube and rod method to prepare the preform for some brittle and low-hardness glasses. Therefore, it is necessary to find a suitable processing technology to improve the processing efficiency of the preform and improve the effect of the preform processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com