Desulfurization catalyst, its preparation method and use

A technology of desulfurization catalyst and iron oxide, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem of insufficient desulfurization accuracy, insufficient desulfurization accuracy of desulfurizer, and no mention of dicalcium ferrite, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

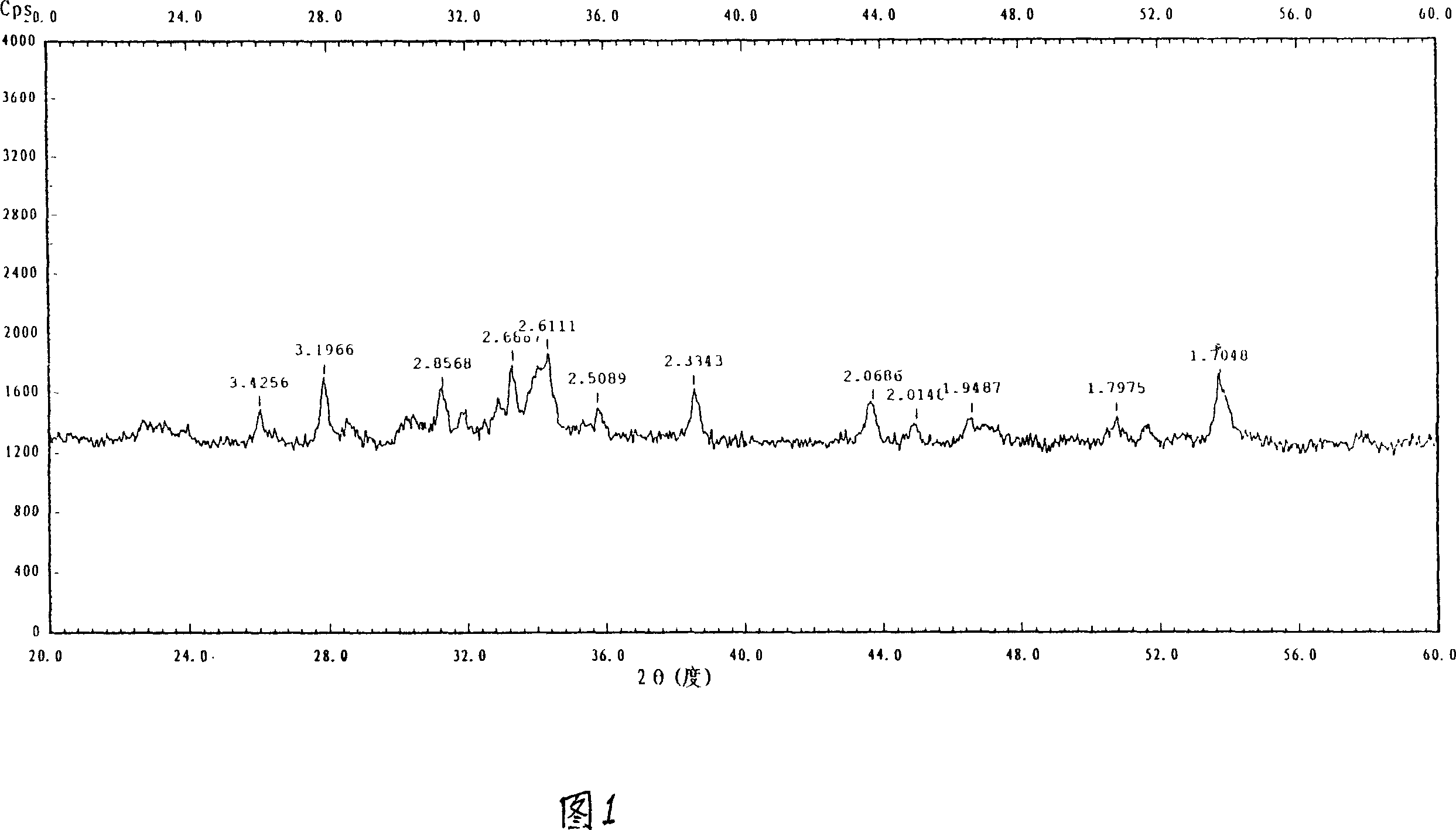

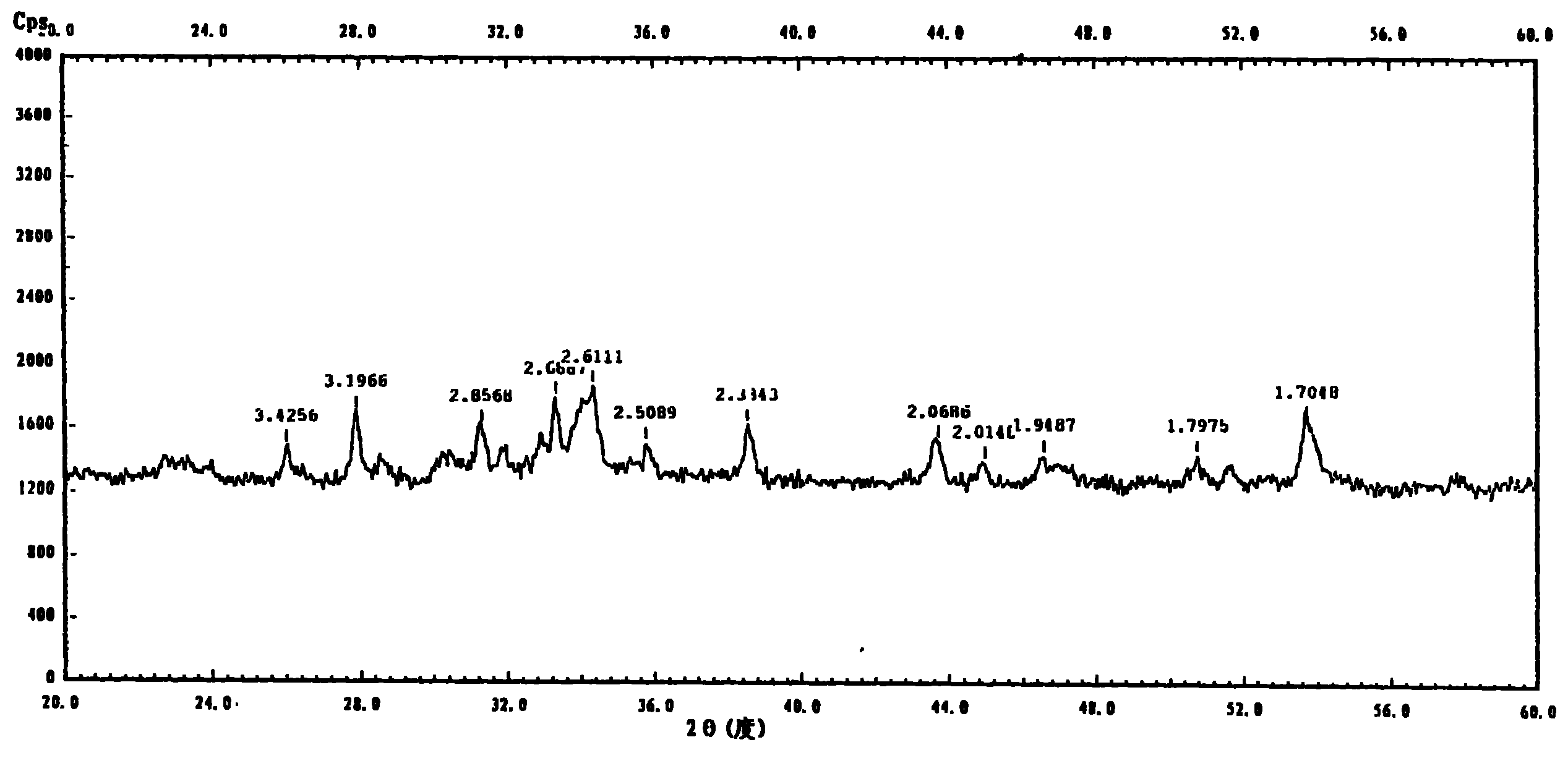

Image

Examples

Embodiment 1

[0033] (Example 1, desulfurization catalyst and preparation method)

[0034] Take Fe 2 o 3 58 grams of powder, 42 grams of CaO powder, add water, stir, knead, extrude, dry at about 100°C for about 2 hours, bake at 900°C in an oxidizing atmosphere for 3 hours, cool and immerse in water for 1 hour, take it out and dry it. Desulfurization catalyst A.

Embodiment 2

[0035] (Example 2, desulfurization catalyst and preparation method)

[0036] Take Fe 2 o 3 48 grams of powder, 50 grams of CaO powder, add water, stir, knead, extrude, dry at about 100°C for about 2 hours, bake at 1000°C in an oxidizing atmosphere for 2 hours, immerse in water for 0.5 hours after cooling, take it out and dry it. Desulfurization catalyst B.

Embodiment 3

[0037] (Example 3, desulfurization catalyst and preparation method)

[0038] Take Fe 2 o 3 61.5 grams of powder, 51 grams of CaO powder, add water, stir, knead, extrude, dry at about 100°C for about 2 hours, bake at 900°C for 3 hours in an oxidative atmosphere, immerse in water for 20 minutes after cooling, take out and dry, Obtain desulfurization catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com