Rear projection screen

A projection screen and projection technology, applied in the field of transmissive screens, can solve problems such as reducing screen performance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

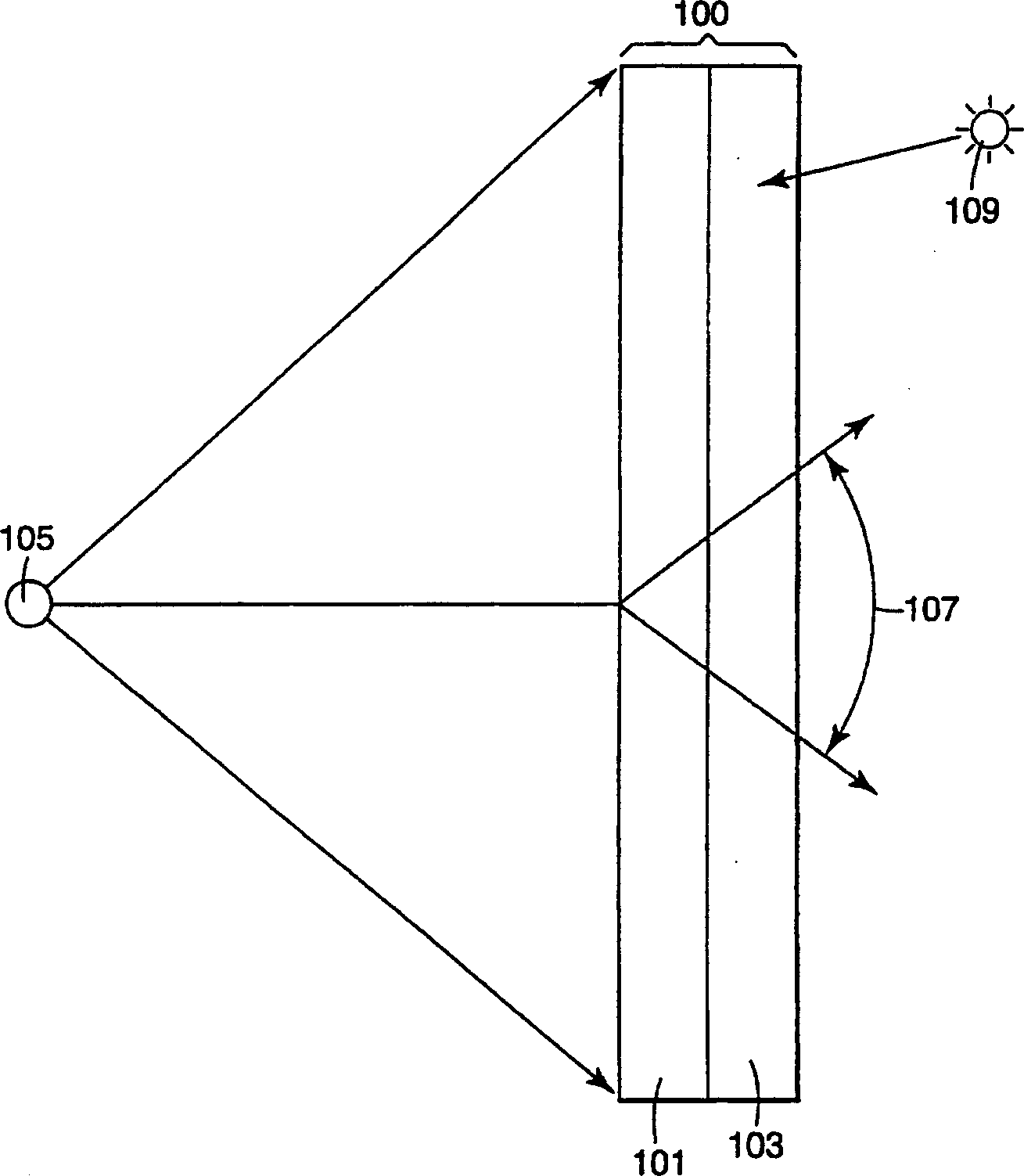

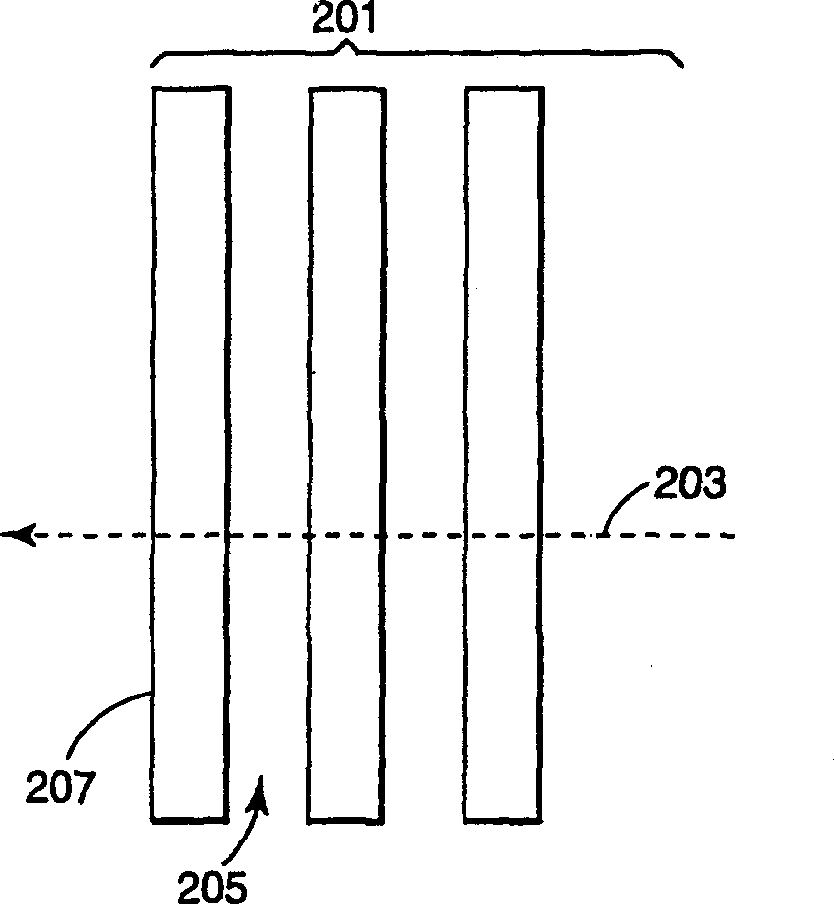

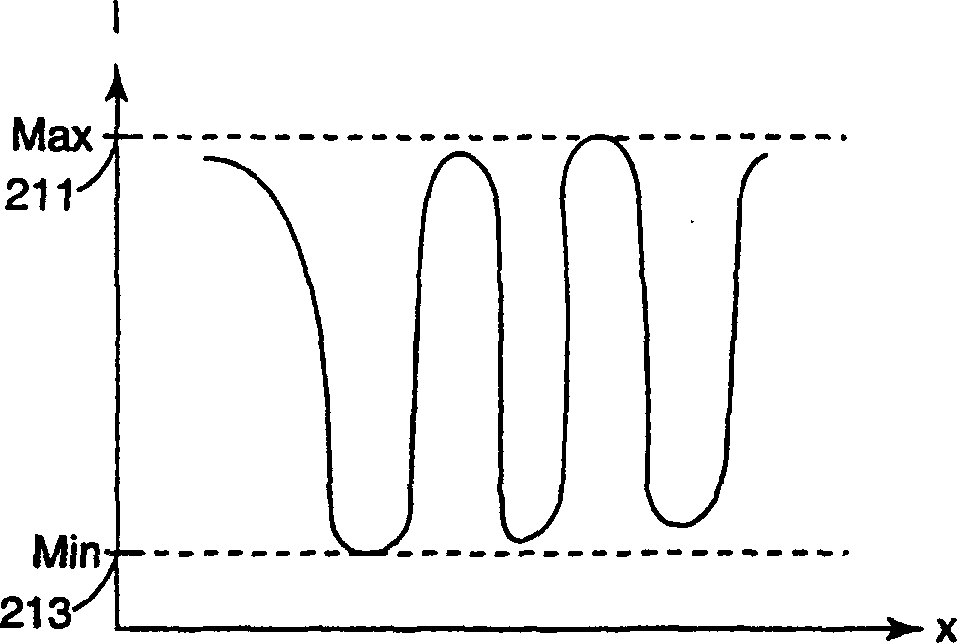

[0077] figure 1 A diffusing element according to the invention and a corresponding increase in modulation depth obtained by combining with a linear polarizer are shown. exist figure 1 In the example of the present invention, the bonding agent is made of 3 kinds of resin components SR9003, SR335 and CN966H90 (Sartomer Company production, Exton, PA) of equal weight plus the photoinitiator (Darocur 4265, Ciba-Geigy Co. .production, Tarrytwon, NY) components. The above resin has a refractive index of about 1.48. Composed of polystyrene and ethylene acrylate copolymers. Particles with a refractive index of 1.54 are dispersed in the resin bond. Particles of the stated type with various refractive indices were produced by Nagase American Corp. (New York, NY). The above mixture was applied to the polycarbonate base to a thickness of approximately 240 μm (9.75 mils). The diffuser element alone has a peak gain of about 0.88, a viewing angle of about 73 degrees and a diffuse reflec...

example 2

[0079] Another embodiment of the invention was made using the mixture described in Example 1. Here, the compound is applied directly to the linear polarizer and cured. The resulting screen assembly has performance comparable to the screen assembly described above, with a similar increase in modulation depth.

example 3

[0081] Eliminate substrates by employing transfer substrates. The transfer substrate was GE8B35 manufactured by General Electric, and included a strong delustering process. A diffuser composition similar to that described in Example 1 was coated on the matte side of a transfer substrate coated with a 2% (IPA) solution of R22764 silicone polyurea fibers (manufactured by 3M Company, St. Paul, MN.). The silicon polyurethane solution has low surface energy and is dried at 70°C before coating the diffuser. After the diffuser was applied to the matte side of the substrate and cured, the assembly was laminated to the linear polarizer and glass support substrate (diffuser side down). The transfer substrate is removed after lamination. After removal of the matte processed transfer substrate, the matte effect remains on the diffuser element. A matte surface means that the specular reflection of the diffusing element is reduced. The overall screen characteristics of the diffuser were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com