Preparation method of needle coke

A technology for needle coke and coal tar, which is used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of limited use range, single reaction raw materials, and difficult industrial conditions, and achieves the promotion of heat transfer and transfer. quality, good optical structure, the effect of promoting high ordering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

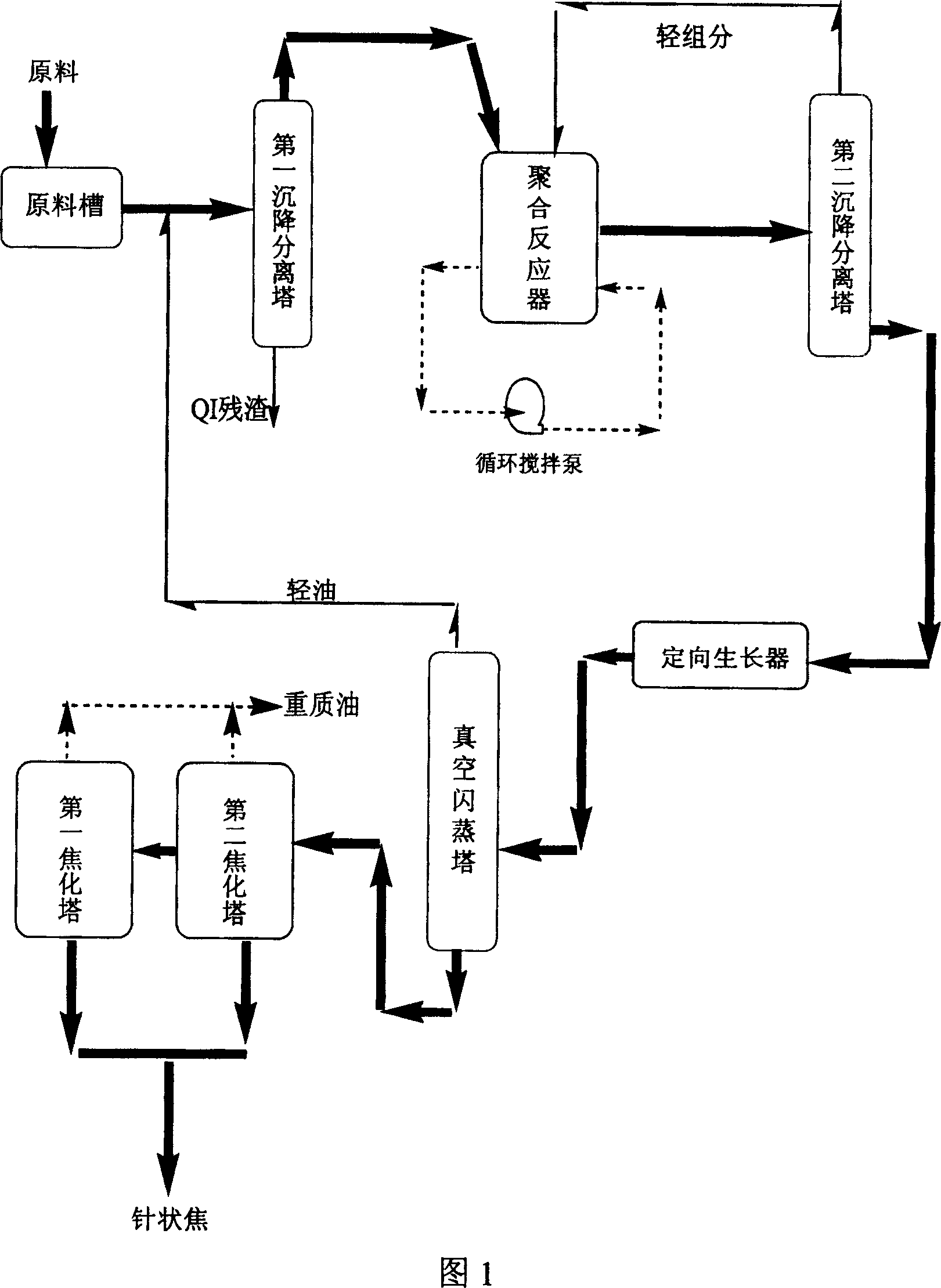

[0021] Below in conjunction with flow chart 1, the present invention is described in further detail: a kind of preparation method of needle coke, operates through the following steps: a. raw material coal tar pitch, soft pitch or coal tar fraction and the light component oil that the vacuum flash tower top condenses according to After mixing in the ratio of 1: (0.5~4), enter the first settling separation tower for static separation, the temperature is controlled at 100~250°C, the residence time of the material in the tower is 0.5~20 hours, and the quinoline-containing insoluble matter is discharged from the bottom of the tower The residue oil of the mixture with the polar easy-to-polymerize component accounts for 5-30% of the feed amount, and the refined asphalt oil containing quinoline insolubles less than 5% flows out from the top of the tower; b. the above-mentioned refined asphalt oil is transported to the polymerization reactor After mixing with the light component oil fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com