Gel coating resin and production thereof

A technology of gel coat resin and manufacturing method, which is applied in the direction of polyester coating, coating, etc., can solve the problem of insufficient thickening and thixotropy of gel coat resin, poor dispersion effect, and poor long-term rheological properties of gel coat resin And other problems, to achieve the effect of high gloss, good practicability, stable weather resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (embodiment 1, gel coat resin)

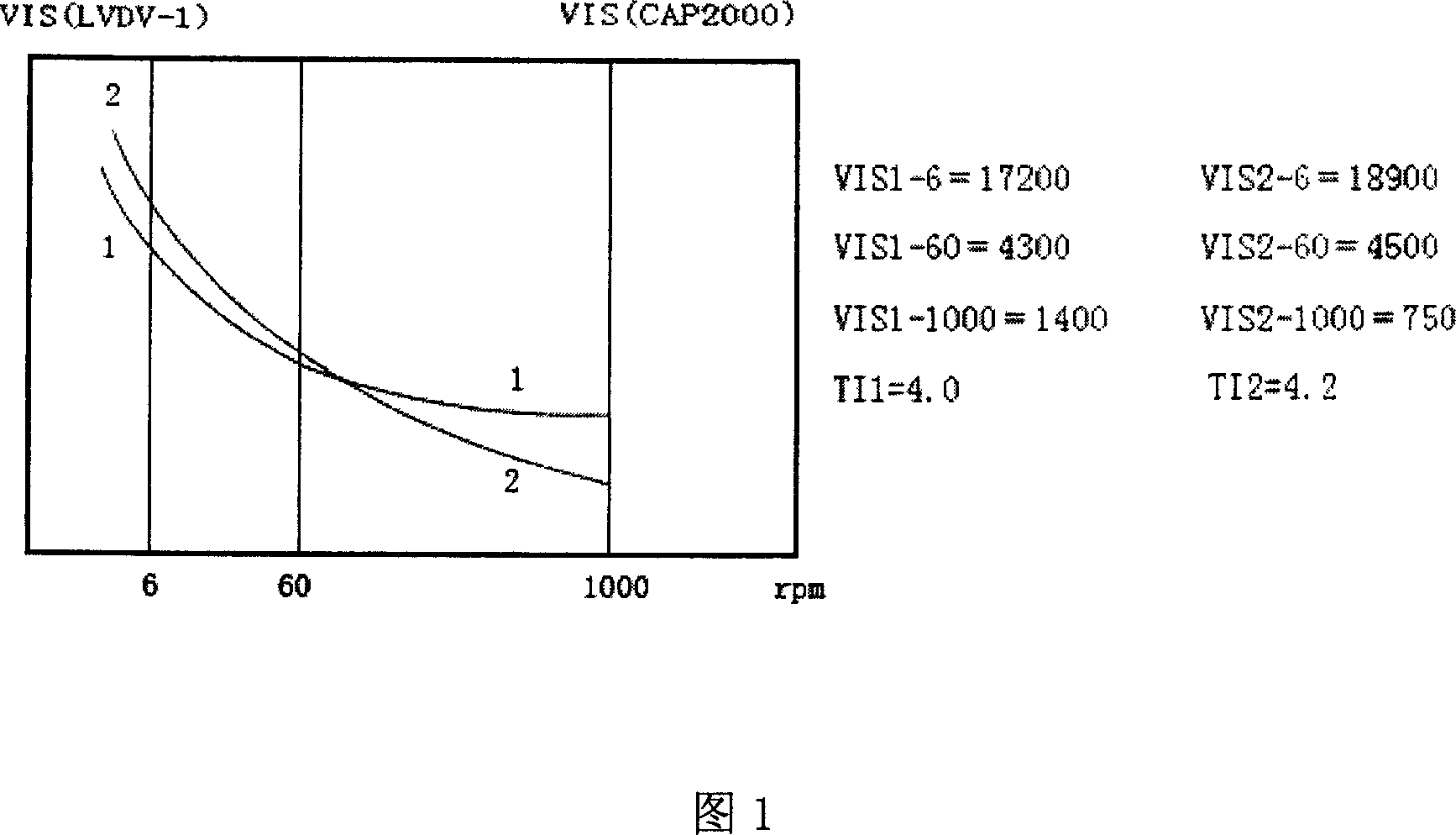

[0036] The gel coat resin in this embodiment is composed of matrix resin, thixotropic agent and liquid additives. Wherein the matrix resin is the ortho-phthalic unsaturated polyester resin in the liquid unsaturated polyester resin, and its brand name, the factory of purchase are shown in Table 2; This unsaturated polyester resin adopts gel permeation chromatography (GPC) to detect, The instrument used is a 515 gel permeation chromatograph (model G02515911M, manufactured by Waters, USA), and the relevant physicochemical parameters obtained are shown in Table 2. The thixotropic agent is powdered fumed silica, which is manufactured by Weikai Company in Germany, and its specific surface area is 210m 2 / g. Liquid additives include defoamers and leveling agents. Among them, the defoaming agent adopts the brand of EFKA2022 liquid organic modified polysiloxane manufactured by Efka Company of the Netherlands, and the leveling agent adopts the ...

Embodiment 2

[0044] (embodiment 2, gel coat resin)

[0045] All the other are identical with embodiment 1, difference is: the specific surface area of used fumed silica is 190m 2 / g, the weight ratio of each component is as follows: 100 parts of liquid matrix resin; 2 parts of powdery fumed silica; 0.1 part of liquid defoamer; 0.1 part of liquid leveling agent. The trade mark, manufacturer and corresponding physicochemical parameters of the matrix resin selected in this embodiment are provided by the corresponding column of table 2; Press GB7193.1-87 measurement method, adopt Brookfield viscometer to measure respectively this gel coat resin at 6rpm / min and the viscosity at 60r / min, the thixotropic index is 4.3; the fineness of the gel coat resin is detected as 20 μm with a scraper fineness meter; the gel coat resin layer obtained after curing and molding is glossy and has a smooth surface without pinholes. The cured and molded gel coat resin layer was tested, and its tensile strength wa...

Embodiment 3

[0046] All the other are identical with embodiment 1, difference is: the specific surface area of used fumed silica is 200m 2 / g, the weight ratio of each component is as follows: 100 parts of liquid matrix resin; 2.2 parts of powdery fumed silica; 0.5 parts of liquid defoamer; 0.5 parts of liquid leveling agent. The grade, manufacturer and corresponding physicochemical parameters of the matrix resin used in this embodiment are provided by the corresponding columns of Table 2; according to the GB7193.1-87 measurement method, the Brookfield viscometer is used to measure the gel coat resin at 6r / min respectively. and the viscosity at 60r / min, the thixotropic index is 4.4; the fineness of the gel coat resin is detected as 10 μm with a scraper fineness meter; the gel coat resin layer obtained after curing and molding is glossy and has a smooth surface without pinholes. The cured and molded gel coat resin layer was tested, and its tensile strength was 70MPa, its elongation was 2.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com