Anti-ultraviolet hardened film

A UV protection and hardening film technology, applied in the direction of radiation-absorbing coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problem of reducing the light transmittance and clarity of the hardened film, changing the color of the hardened film, and easily releasing small molecules, etc. problem, to achieve the effect of reducing the UV protection effect and stabilizing the weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072]

[0073]

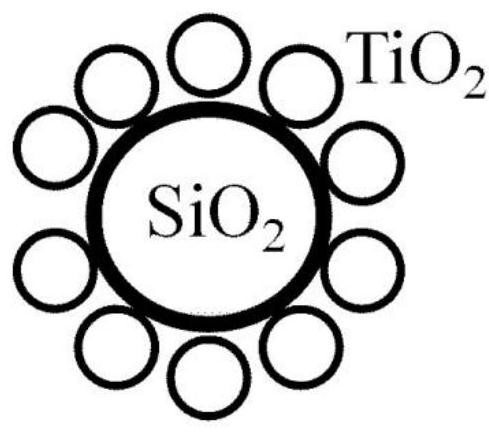

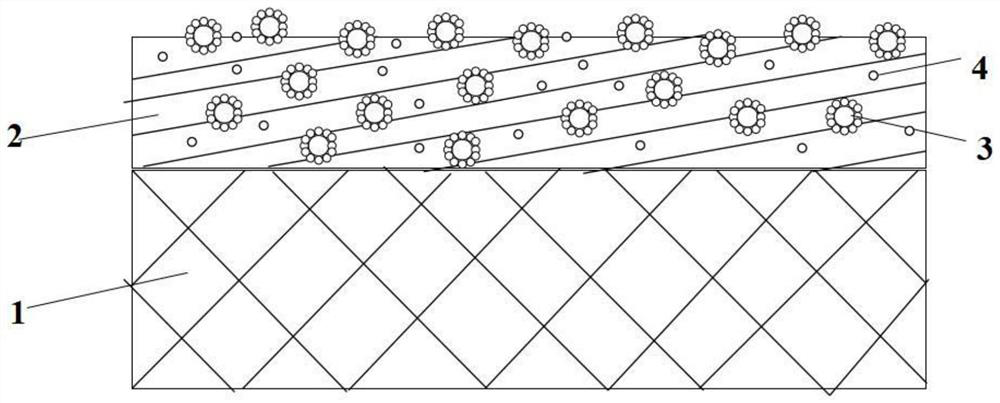

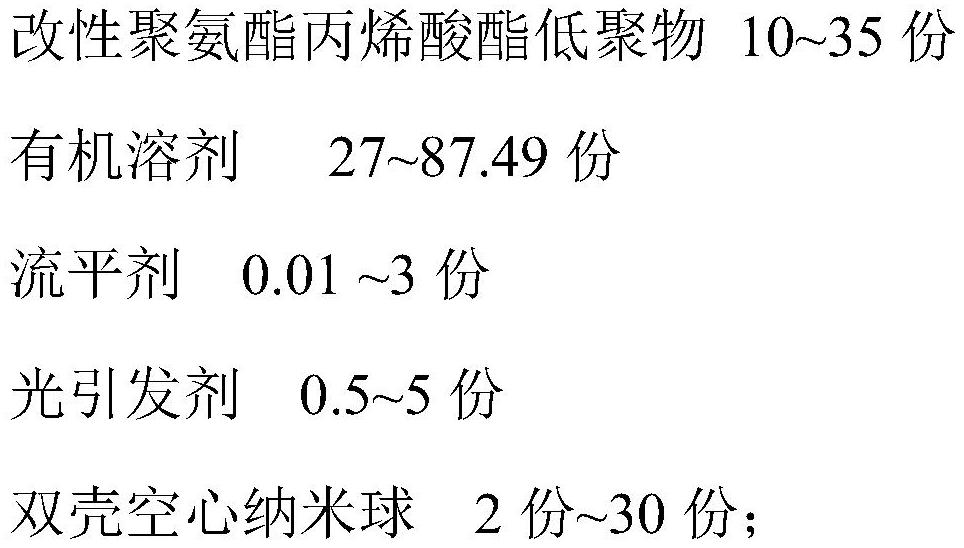

[0074]After modifying 20 parts by weight of urethane acrylate UVU6906 of Xilaiwu Company, add it to 87.49 parts by weight of mixed solvent to swell and stir evenly. The mixed solvent is 35 parts by weight of methyl isobutyl ketone, 35 parts by weight of ethyl acetate and 17.49 parts by weight. parts by weight toluene. Add 0.01 parts by weight of polyether silicone leveling agent (BYK-378 from Sapphire) into the solution, continue to add 0.5 parts by weight of photoinitiator 1-hydroxycyclohexyl phenyl ketone, and stir for 20 minutes. Finally, 2 parts by weight of double-shell hollow nanosphere particles composed of silicon dioxide and titanium dioxide were added for 30 minutes of high-speed stirring and dispersion at a stirring speed of 1200 r / min.

[0075] Use a wire bar coater to coat the coating solution on one side of an optical-grade polytriacetate cellulose film (TAC film) with a thickness of 80 μm, dry it in an oven at 60 ° C for 3 min, and irradi...

Embodiment 2

[0077]

[0078] 15 parts by weight of urethane acrylate UVU6208 of Xilaiwu Company are modified and then added to 62 parts by weight of mixed solvent to swell and stir evenly. The mixed solvent is 24 parts by weight of methyl isobutyl ketone, 24 parts by weight of ethyl acetate and 14 parts by weight parts by weight toluene. Add 1.5 parts by weight of polyether silicone leveling agent (BYK-399 from Sapphire) into the solution, continue to add 1.5 parts by weight of photoinitiator 1-hydroxycyclohexyl phenyl ketone, and stir for 20 min. Finally, 20 parts by weight of double-shell hollow nanosphere particles composed of silicon dioxide and titanium dioxide were added for 40 minutes of high-speed stirring and dispersion at a stirring speed of 1200 r / min.

[0079] Use a wire bar coater to coat the coating solution on one side of an optical-grade polytriacetate cellulose film (TAC film) with a thickness of 80 μm, dry it in an oven at 60 ° C for 3 min, and irradiate it with ultrav...

Embodiment 3

[0081]

[0082] After modifying 15 parts by weight of DSM's polyurethane acrylate Agisyn 670A2, add it to 77 parts by weight of mixed solvent to swell and stir evenly. The mixed solvent is 30 parts by weight of methyl isobutyl ketone, 30 parts by weight of ethyl acetate and 17 parts by weight toluene. Add 1.5 parts by weight of polyether silicone leveling agent (BYK-3751 from Sapphire) into the solution, continue to add 1.5 parts by weight of photoinitiator 1-hydroxycyclohexyl phenyl ketone, and stir for 20 min. Finally, 5 parts by weight of double-shell hollow nanosphere particles composed of silicon dioxide and titanium dioxide were added for 20 minutes of high-speed stirring and dispersion at a stirring speed of 1200 r / min.

[0083] Use a wire bar coater to coat the coating solution on one side of an optical-grade polytriacetate cellulose film (TAC film) with a thickness of 80 μm, dry it in an oven at 60 ° C for 3 min, and irradiate it with ultraviolet light to dry it. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com