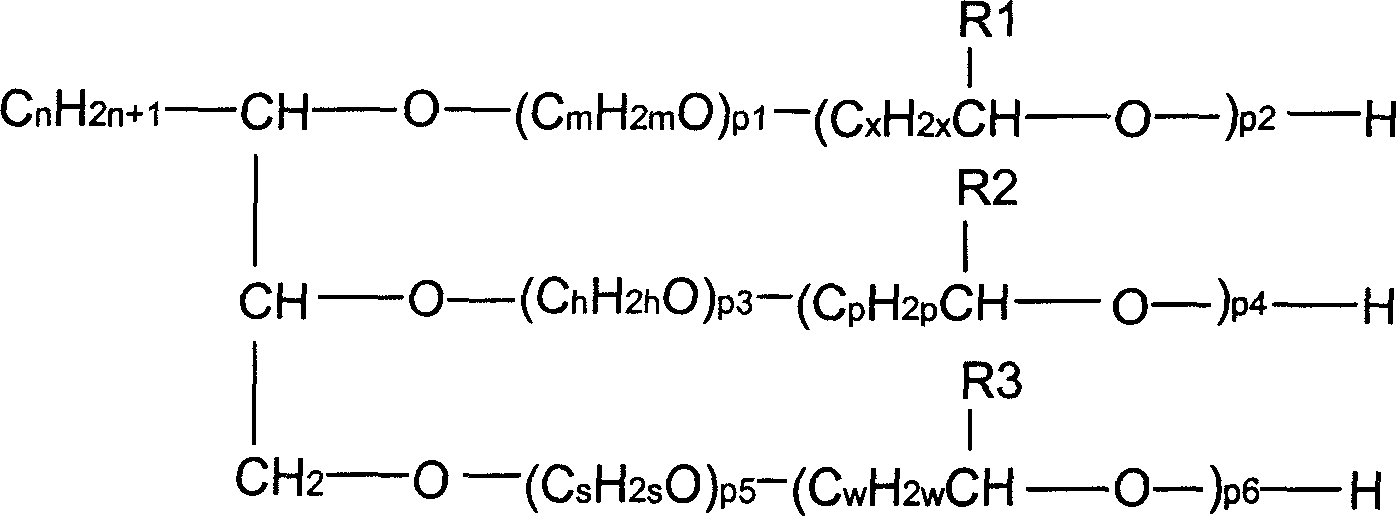

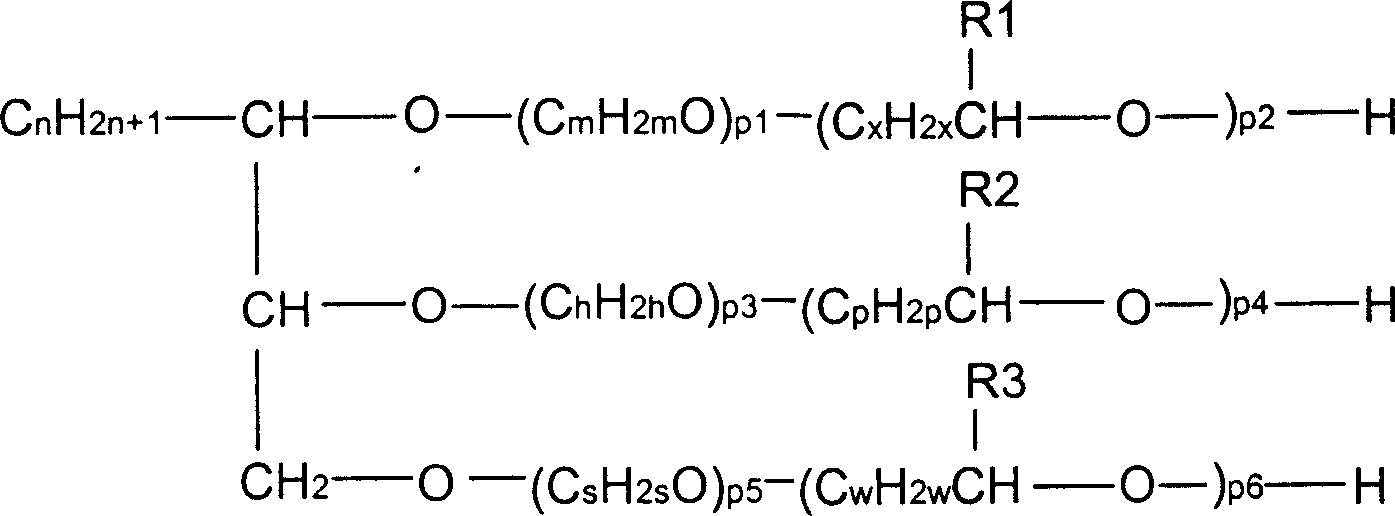

Method of removing micro C1-C7 low carbon component in polyether poly hydric alcohol

A polyether polyol, C1-C7 technology, applied in the field of removing trace C1-C7 low-carbon components in polyether polyol, can solve the problems of adverse effects on drilling fluid performance, increased analysis results, interference with geological logging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Pump the polyether polyol material into the reactor, turn on the vacuum system, control the temperature at 110°C, the pressure at 0.02Mpa, and the time for 6 hours to remove a small amount of C1-C7 components in the material, and then lower the temperature to 40°C. Outgoing packaging. According to the Petroleum and Natural Gas Industry Standard of the People's Republic of China SY5259-91 "Gas Chromatographic Analysis Method for Light Hydrocarbons in Debris Tank Top Gas", the light hydrocarbon samples naturally desorbed from the material are separated in the chromatographic column and detected by a hydrogen flame detector. After data processing, the content of each component of C1-C7 light hydrocarbons was obtained.

[0021] Test results: methane 12.42 μL / L, ethane 32.45 μL / L, propane 46368.23 μL / L, others were not detected, the total amount was 46413.1 μL / L. The fluorescence of 2% polyether polyol lubricant aqueous solution was measured by YZ-1 petroleum fluorescence a...

Embodiment 2

[0023] The polyether polyol material is pumped into the reactor, nitrogen gas with a purity of 99.99% is introduced into the reactor system, the vacuum system is turned on, the temperature is controlled at 100°C, the pressure is 0.04Mpa, the time is 3 hours, and the flow rate of the inert gas is 7 kg / hour to remove traces of C1-C7 components in the material, then cool down to 40°C, and pack out the material. According to the Petroleum and Natural Gas Industry Standard of the People's Republic of China SY5259-91 "Gas Chromatographic Analysis Method for Light Hydrocarbons in Debris Tank Top Gas", the light hydrocarbon samples naturally desorbed from the material are separated in the chromatographic column and detected by a hydrogen flame detector. After data processing, the content of each component of C1-C7 light hydrocarbons was obtained.

[0024] Test results: methane 32.48 μL / L, ethane 28.43 μL / L, propane 19185.79 μL / L, others were not detected, the total amount was 19246.7 ...

Embodiment 3

[0026] The polyether polyol material is pumped into the reactor, nitrogen gas with a purity of 99.9% is introduced into the reactor system, the vacuum system is turned on, the temperature is controlled at 120°C, the pressure is 0.06Mpa, the time is 2 hours, and the inert gas flow rate is 8 kg / hour, to remove trace C1-C7 components in the material, then cool down to 30°C, and pack out the material. According to the Petroleum and Natural Gas Industry Standard of the People's Republic of China SY5259-91 "Gas Chromatographic Analysis Method for Light Hydrocarbons in Debris Tank Top Gas", the light hydrocarbon samples naturally desorbed from the material are separated in the chromatographic column and detected by a hydrogen flame detector. After data processing, the content of each component of C1-C7 light hydrocarbons was obtained. Test results: Propane 312.96 μL / L, others were not detected, the total amount was 312.96 μL / L. The fluorescence of 2% polyether polyol lubricant aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com