Dielectric ceramic composition

A technology of dielectric ceramics and composites, applied in the field of multilayer ceramic substrates, can solve problems such as not found, and achieve the effect of high relative permittivity and low temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

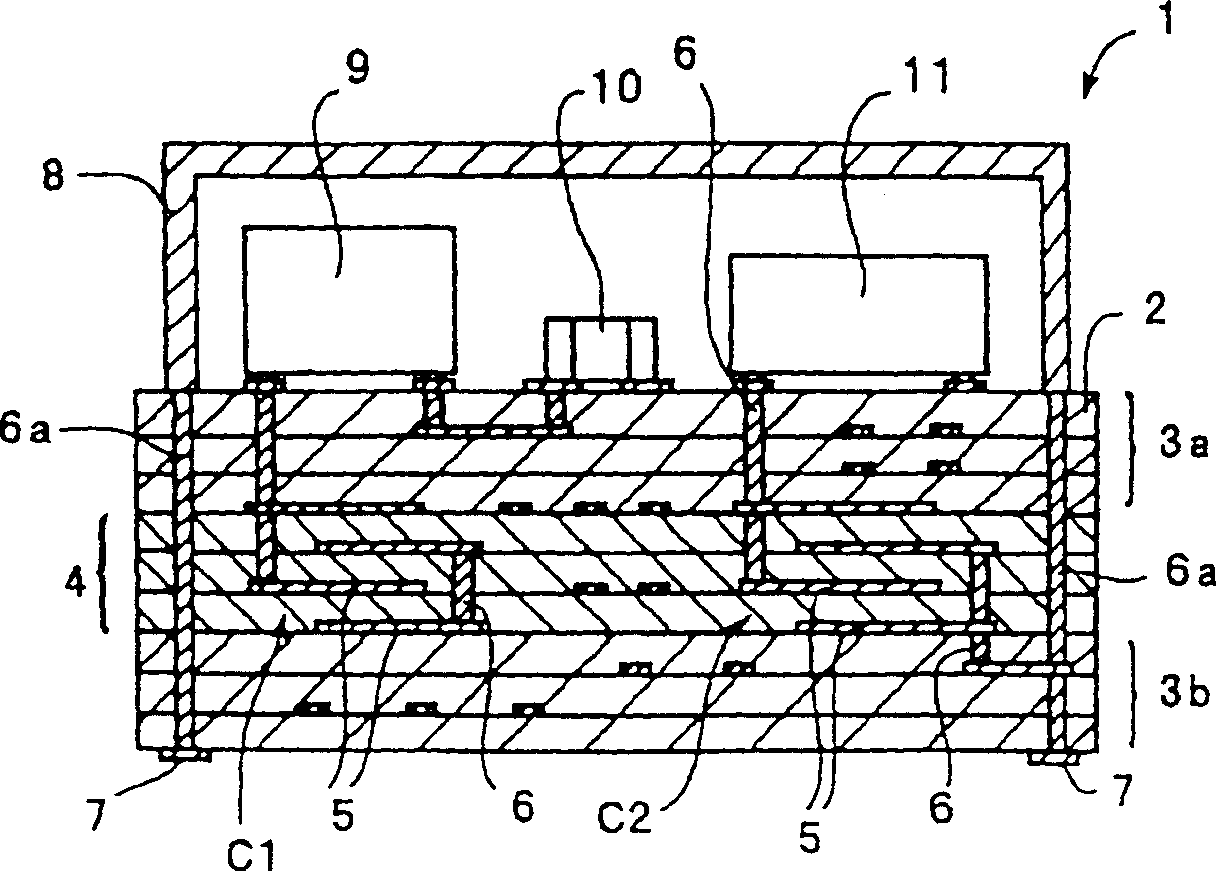

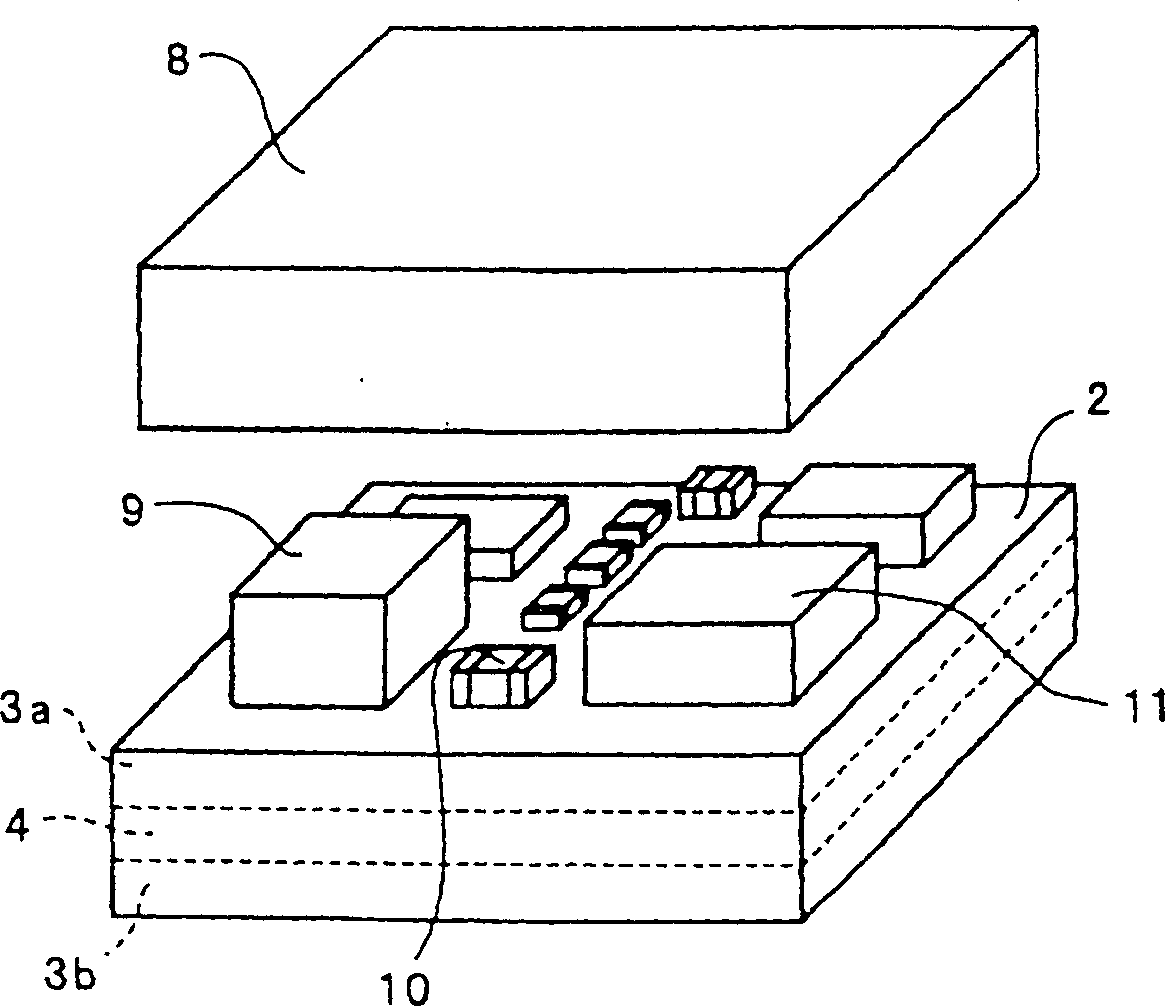

[0018] The present invention will be described in detail below.

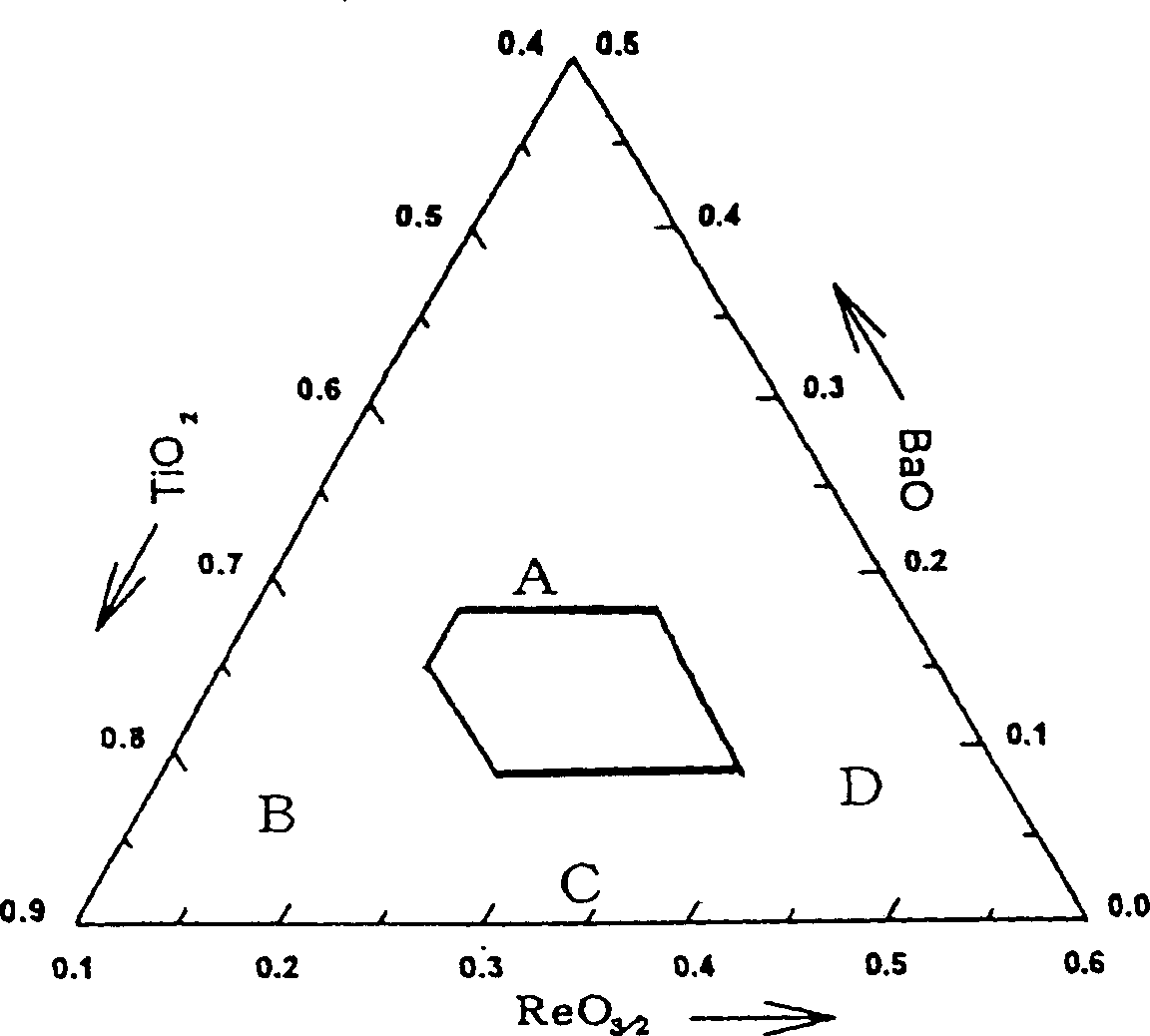

[0019] In the present invention, due to the use of BaO-TiO based 2 -ReO 3 / 2 The formula xBaO-yTiO 2 -zReO 3 / 2 The indicated ceramic components and the above-mentioned special glass components are used as the main components, so as will be demonstrated in the following examples, sintering can be carried out at a low temperature of not more than 1100 ° C, preferably 1000 ° C or lower, thereby enabling Sintering is carried out with metals with good electrical conductivity, such as gold, silver or copper.

[0020] In addition, a dielectric ceramic compact having a low temperature coefficient and a high relative permittivity in a high frequency band (specifically, in a microwave band and a milliwave band) can be produced by sintering the dielectric ceramic composition .

[0021] Furthermore, when a glass component composed of a glass composition is crystallized, or when a BaO-TiO-based 2 -ReO 3 / 2 When the cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com