Purifying method for carbon dioxide containing air flow

A technology of carbon dioxide and gaseous state, applied in the direction of organic chemical methods, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the replacement frequency of potassium carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

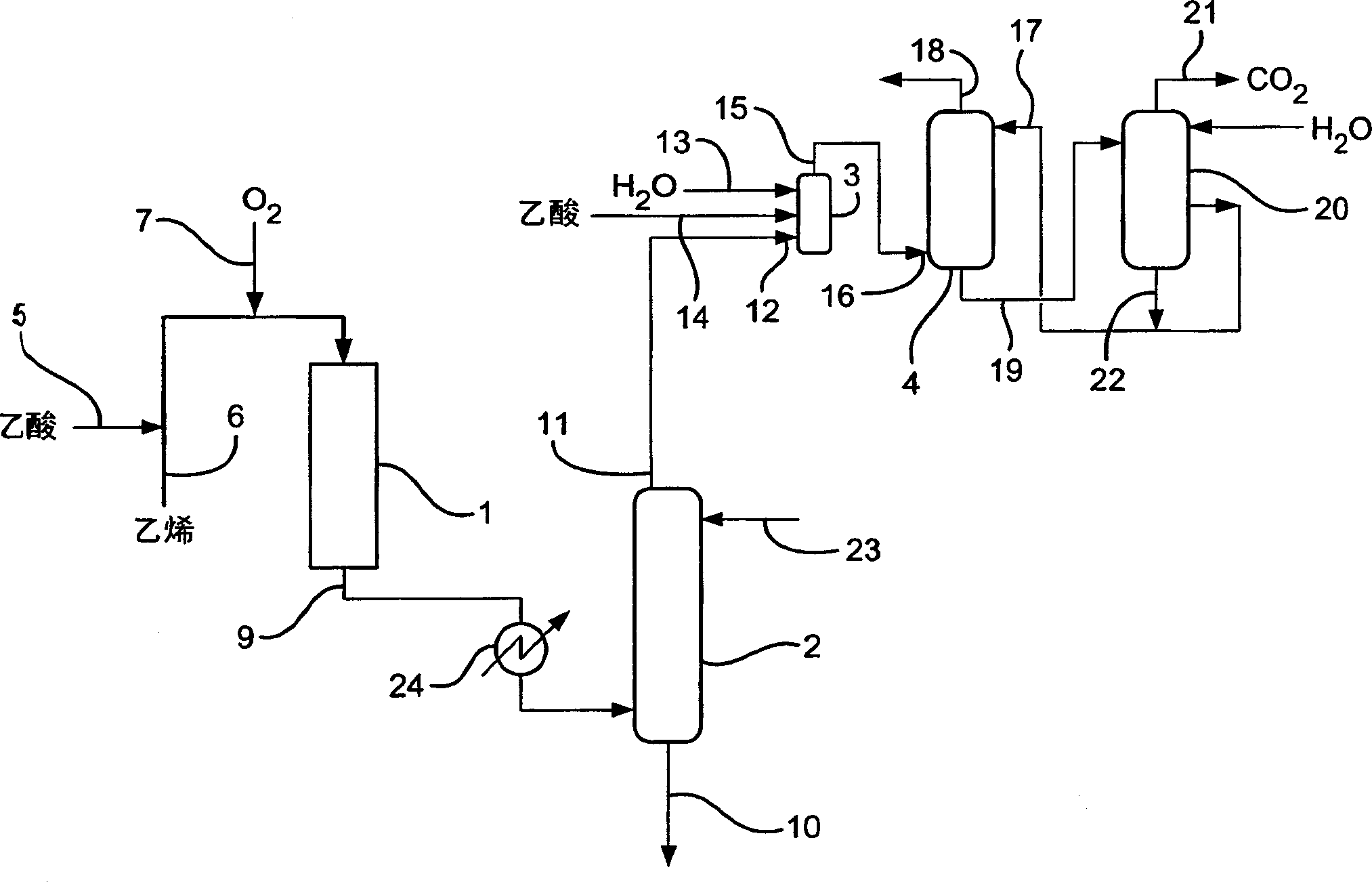

[0043] use as figure 1 As described, but without feeding acetic acid to the scrubber, the reactor was filled with palladium / gold catalyst on silica. A potassium acetate co-catalyst solution was injected from the inlet of the reactor. The reactor was operated at 160°C and 120 psig (8 barg). The mole percentage of the total feed composition entering the catalytic bed is ethylene: oxygen: acetic acid: inert gas 56:5:16:5.

[0044] The gas exiting the reactor was passed to an absorption column operated at 7 barg and 30-40°C and quenched with recycled acetic acid. The gaseous by-products are fed to the scrubber together with 40Kg / hr of water. The scrubbed gaseous fraction was passed to a Benfield carbon dioxide removal unit filled with potassium carbonate solution to remove carbon dioxide. The solution containing absorbed carbon dioxide is passed to a stripper where the carbon dioxide is stripped and evacuated to the atmosphere, and the regenerated potassium carbonate solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com