Method for preparing polymer gradient material by using electric field

A gradient material and polymer technology, applied in the preparation of polymer mixture gradient materials, in the field of preparation of polymer mixture gradient materials, can solve the problem that the degree of gradient is not easy to control, and achieve the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

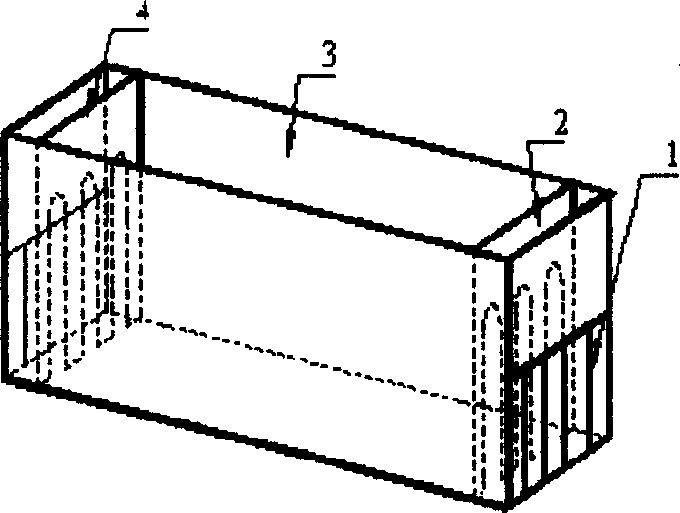

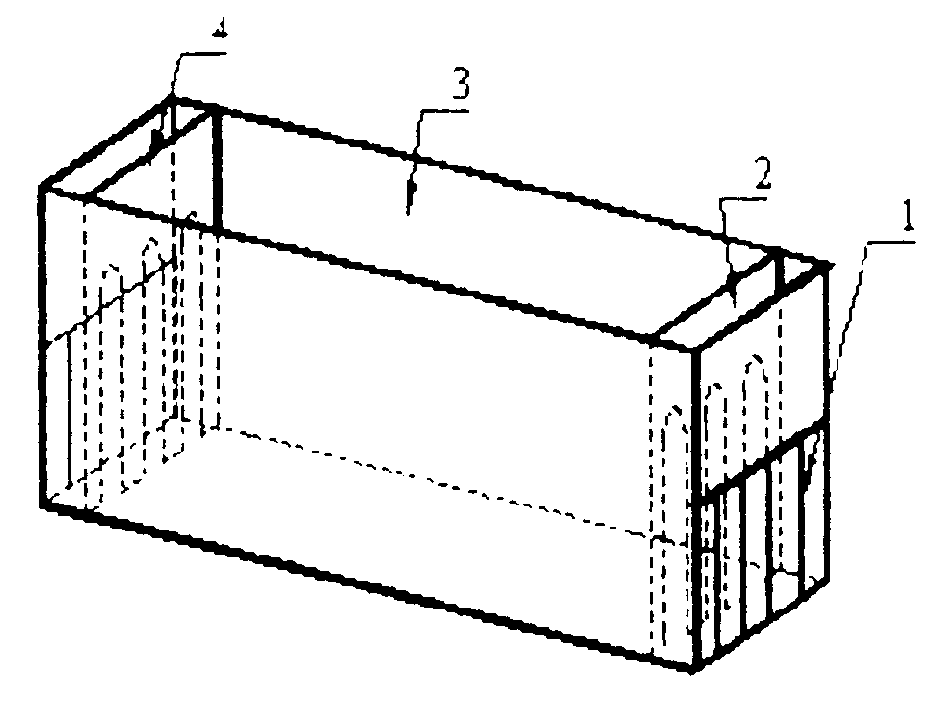

[0017] Mix polyvinyl alcohol (PVA) and polyacrylic acid (PAA) (or polyacrylate partially neutralized with NaOH solution) in various proportions to make a 2% (g / g) aqueous solution, and pour a certain amount into the electrode material In the self-made electrolytic cell of Pt (the schematic diagram of the electrolytic cell is as figure 1 ). Place the electrolytic cell in a constant temperature box at 50°C, and apply a DC voltage of 40V between the two electrodes.

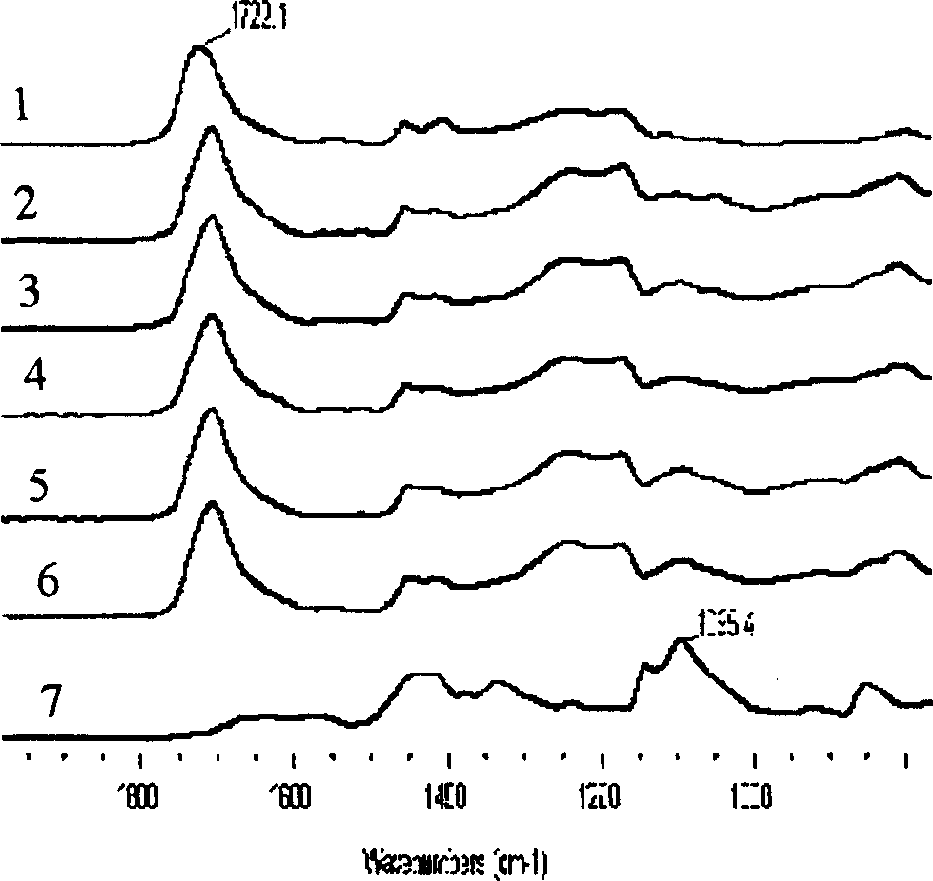

[0018] After 16 hours, the sample solvent was evaporated to dryness, then the power was cut off and dried. The blend film was taken out and the composition of the sample was tested at multiple points along the direction of the electric field by infrared reflection, and an obvious and continuous composition gradient was found. figure 2 It is the reflection infrared spectrogram of the PVA / PAA (70 / 30) blend aqueous solution solvent evaporated and dried, the obtained blend film from the electric field negative electro...

Embodiment 2

[0021] Prepare polyvinylpyrrolidone (PVP) and polystyrenesulfonic acid (or partially neutralized polystyrenesulfonate with NaOH solution) (70 / 30) into an 8% (g / g) aqueous solution, take a certain amount and pour Into the self-made electrolytic cell whose electrode material is Pt (the schematic diagram of the electrolytic cell is shown in figure 1 ). Place the electrolytic cell in a constant temperature box at 30°C, and apply a DC voltage of 70V between the two electrodes. The solvent is gradually evaporated and electrolyzed. After the solvent is completely evaporated to dryness, the power is turned off and dried to obtain a blend film with a gradient composition of polyvinylpyrrolidone and polystyrenesulfonic acid.

Embodiment 3

[0023] Polyvinyl alcohol (PVA) and polyethyleneimine hydrochloride (60 / 40) were formulated into a 2% (g / g) aqueous solution, and a certain amount was poured into a self-made electrolytic cell whose electrode material was Pt. Place the electrolytic cell in a constant temperature box at 60°C, and apply a DC voltage of 30V between the two electrodes. The solvent is gradually evaporated and electrolyzed. After the solvent is completely evaporated to dryness, the power is turned off and dried to obtain a blend film with a gradient composition of polyvinyl alcohol (PVA) and polyethyleneimine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com